End cover structure capable of preventing oil seal from being separated out

An end cap and oil-proof technology, applied in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of increasing the pressure output of the oil seal, difficulty in assembly, and increasing the pressing force of the oil seal, so as to increase the resistance and improve the Product quality, the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail below in conjunction with accompanying drawing:

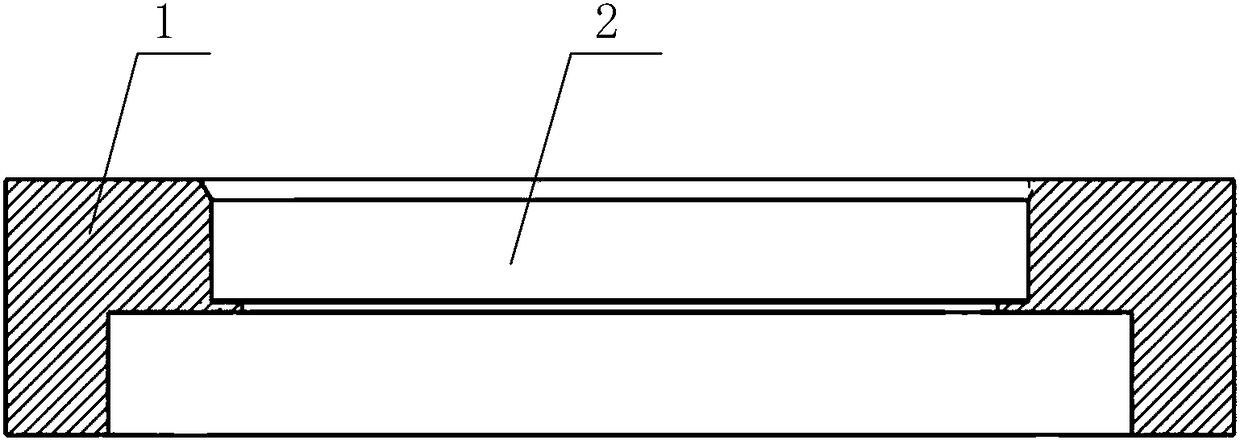

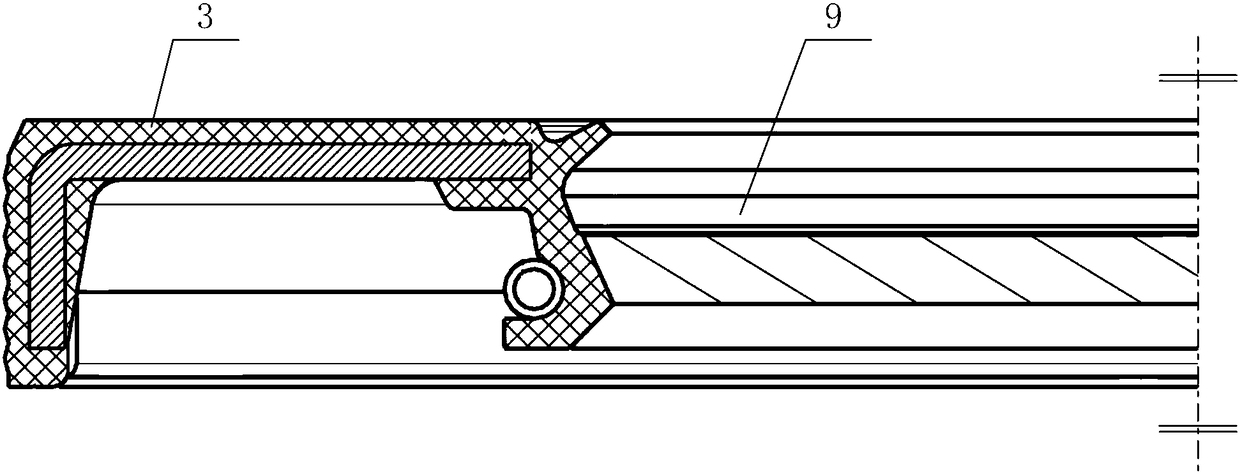

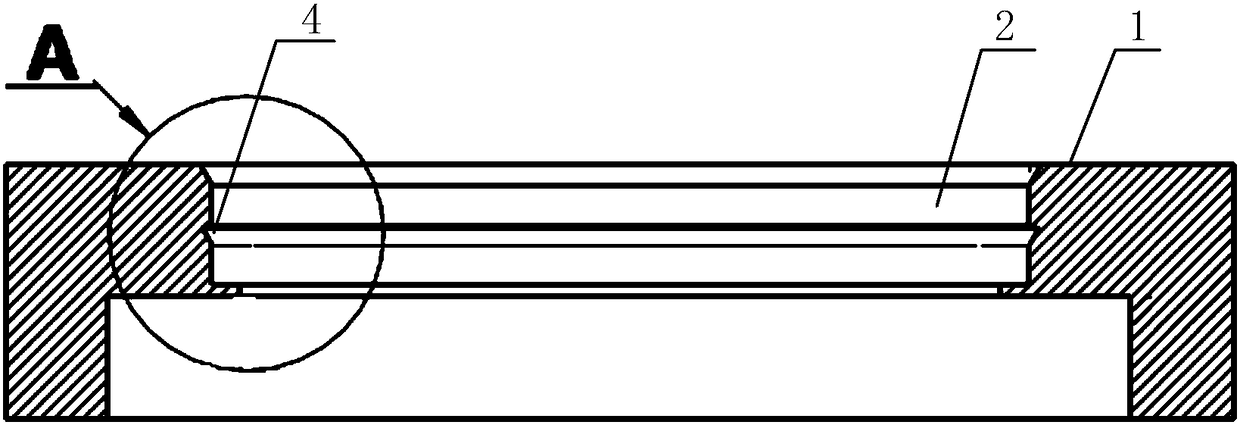

[0033] The invention discloses an end cover structure for preventing oil seal from falling out. The end cover 1 is provided with an upper through hole 2, a gland 9 is installed in the upper through hole 2, an oil seal 3 is installed between the upper through hole 2 and the gland 9, and the upper The through hole 2 has a groove 4 on its side wall, and the side wall of the upper through hole 2 is divided into the first inner wall 5, the second inner wall 6 and the third inner wall 7 from the top of the upper through hole 2 downwards, and the upper through hole 2 The lower edge is provided with an inward protrusion 8.

[0034] see figure 1 and figure 2 , figure 1 It is an ordinary end cover, and an upper through hole 2 is opened in the middle of the end cover 1; figure 2 It is a schematic diagram of installing the oil seal 3 on the end cover 1. A gland 9 is installe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com