A Height Adjustable Turning Tool with Inverted Bevel Contact

A contact-type, inverted bevel technology, applied in the direction of tool holders, etc., can solve the problems of poor flatness of gaskets, parts that cannot be cut, and knife punching, etc., to achieve the effects of strengthening anti-expansion ability, easy adjustment and installation, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

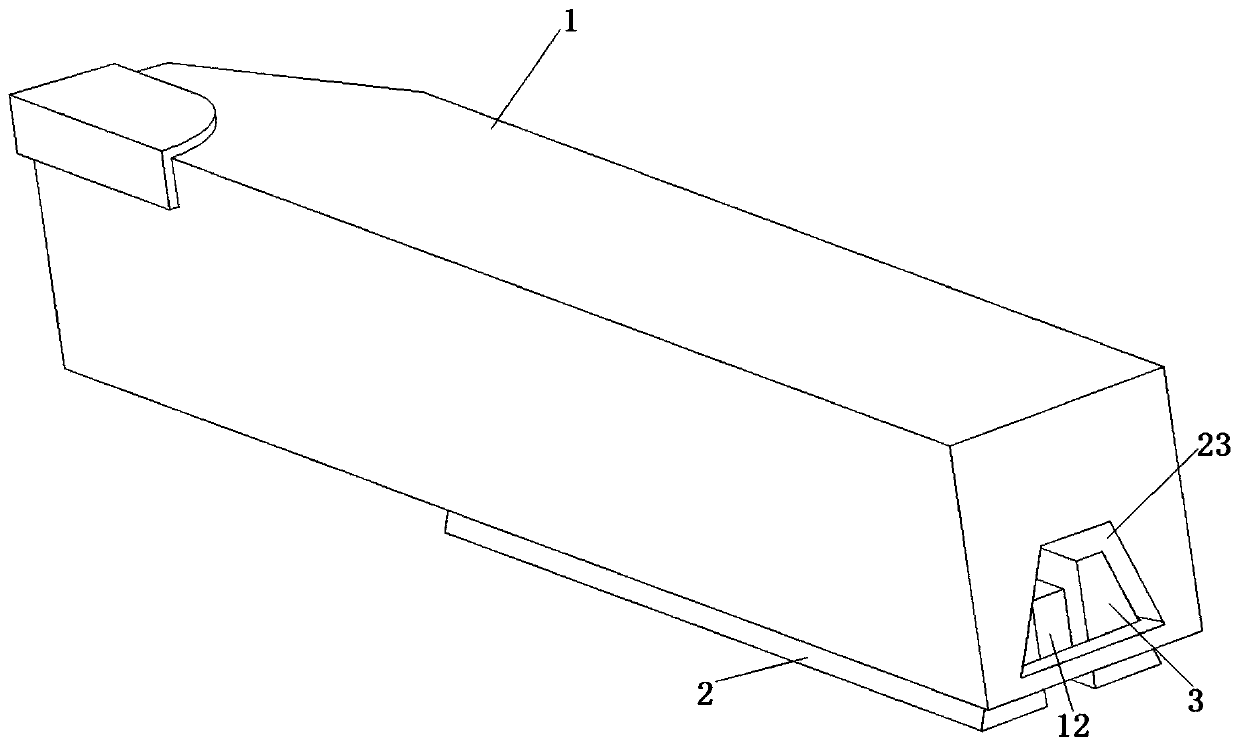

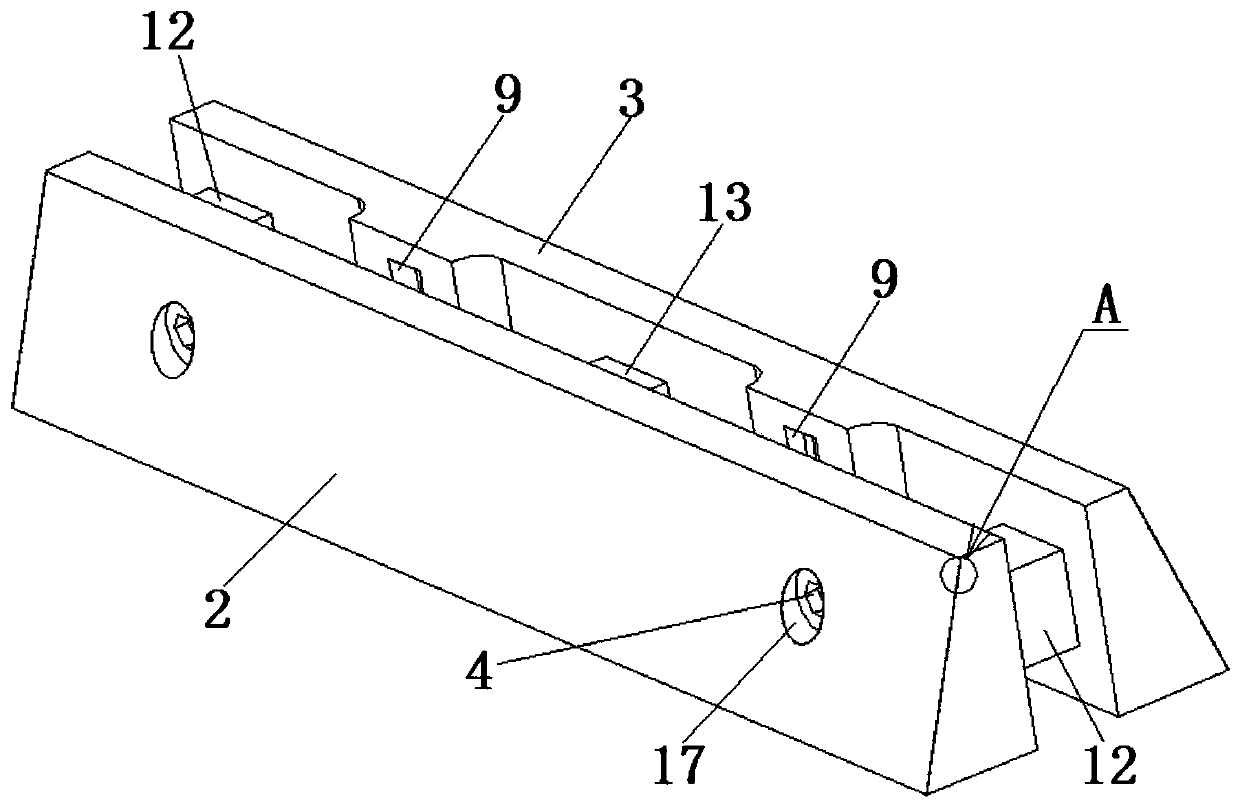

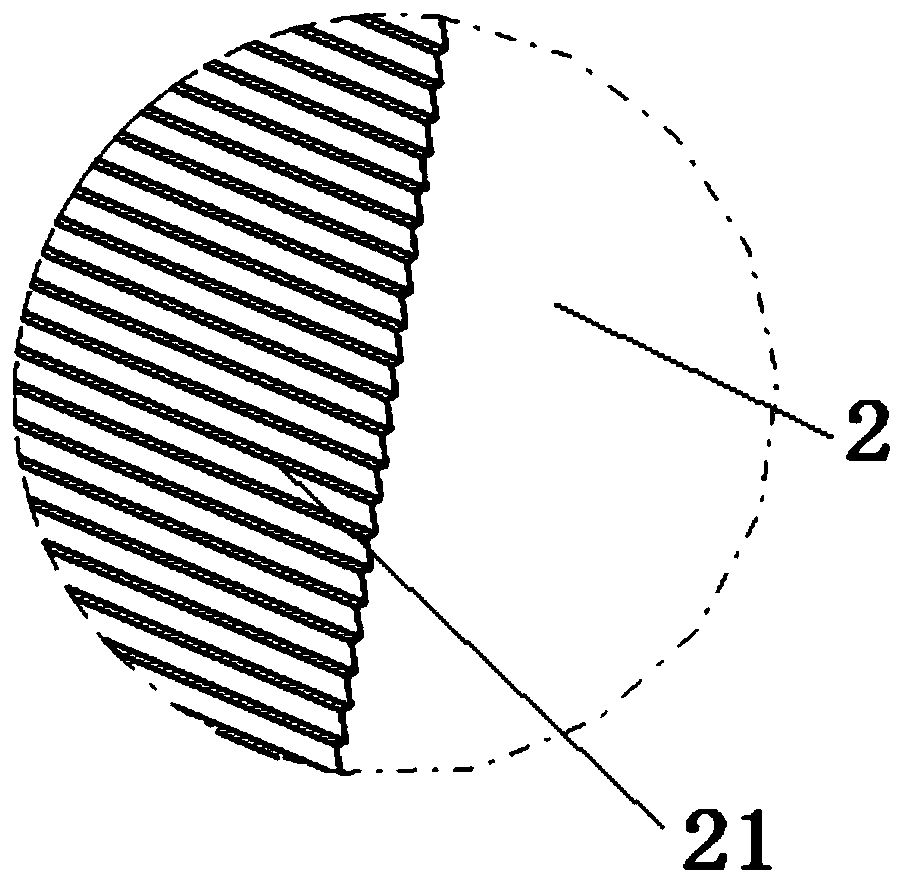

[0050] The invention is an eccentric height adjustable turning tool, the structure is as follows figure 1 , figure 2 , Figure 9 , Figure 12 , Figure 13 , Figure 16 , Figure 23 , Figure 24 with Figure 25As shown, including the cutter body 1, the bottom of the cutter body 1 is provided with an inverted trapezoidal groove c16, and the left inclined plane support body 2 and the right inclined plane support body 3 are installed inside the groove c16, and the left inclined plane support body 2 and the right inclined plane support body 3 The inclined planes are placed facing away from each other, the left inclined plane support body 2 is connected with the right inclined plane support body 3 through a sleeve mechanism, the left inclined plane support body 2 and the right inclined plane support body 3 are jointly provided with a slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com