Track plate body positioning and welding tool and welding process thereof

A technology of positioning welding and track shoes, which is applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of reduced vehicle stability, unevenness of two track shoes, failure of track acceleration, etc., to achieve stable performance and assembly Requirements, effects of driving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

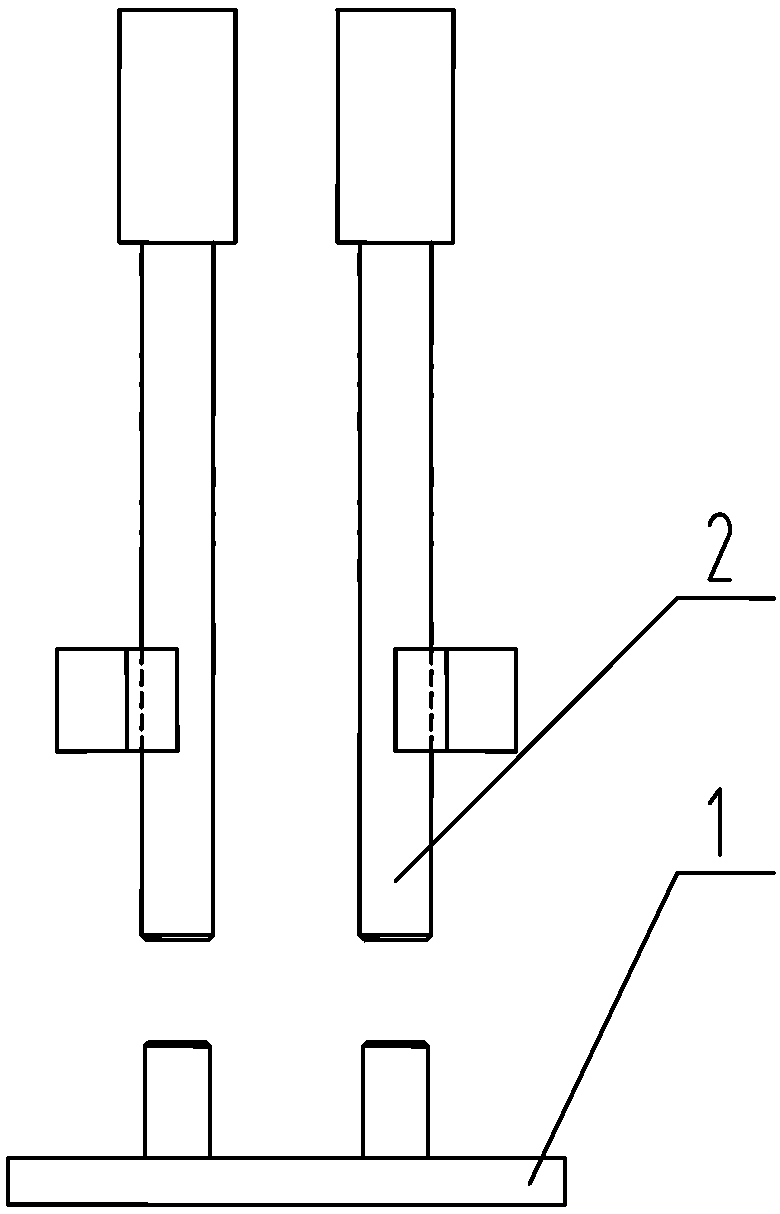

[0029] A track shoe body positioning welding tool of the present invention comprises a base 1 and a positioning member 2 .

[0030] Such as figure 2 , 3 Shown; Base 1 is used to place a track shoe vertically, the position to be welded is upward, and is effectively fixed.

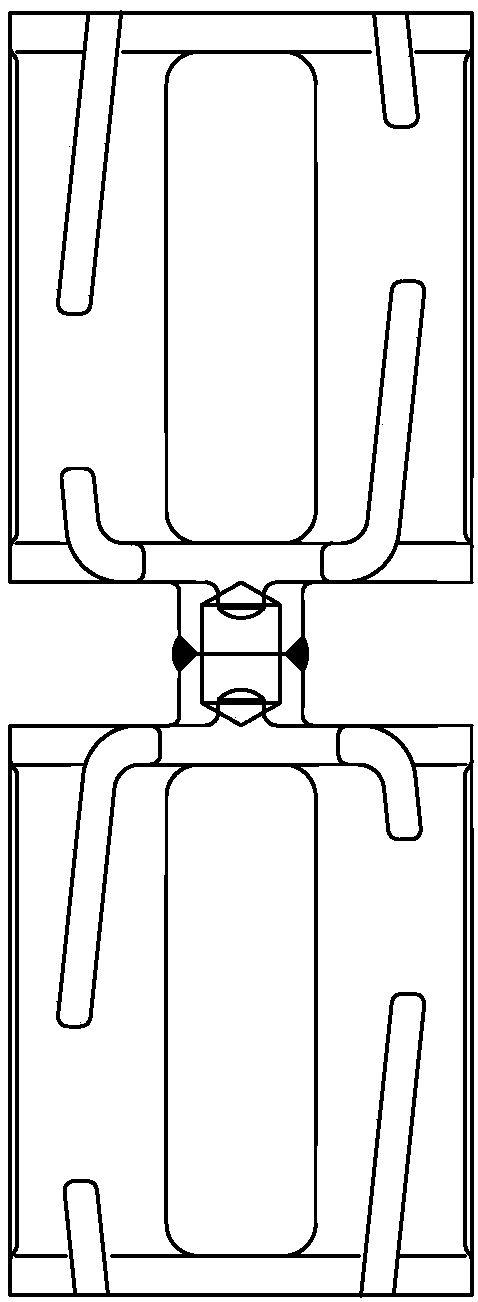

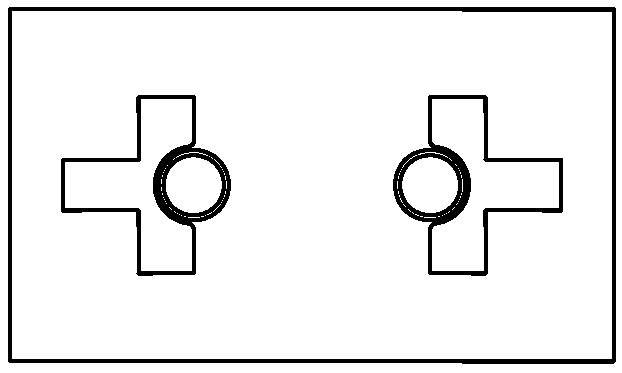

[0031] The positioning part 2 is to insert the two positioning pins 5 into the holes of the two track shoes respectively, and the position is limited by the limit block 6, so that the other track shoe can be reliably positioned with the first track shoe, ensuring the coaxiality and position , to meet the positioning requirements.

[0032] Further, as Figure 4 As shown: the base 1 includes: a bottom plate 3 and a pillar 4 .

[0033] The base plate 3 is placed horizontally, and the two pillars 4 are respectively inserte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com