A purlin part

A component and purlin technology, applied in the field of purlin components, can solve the problems of no standardized connection size, cannot be reused, low support stiffness, etc., and achieve the effect of convenient disassembly and transportation, saving construction costs, and large construction space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

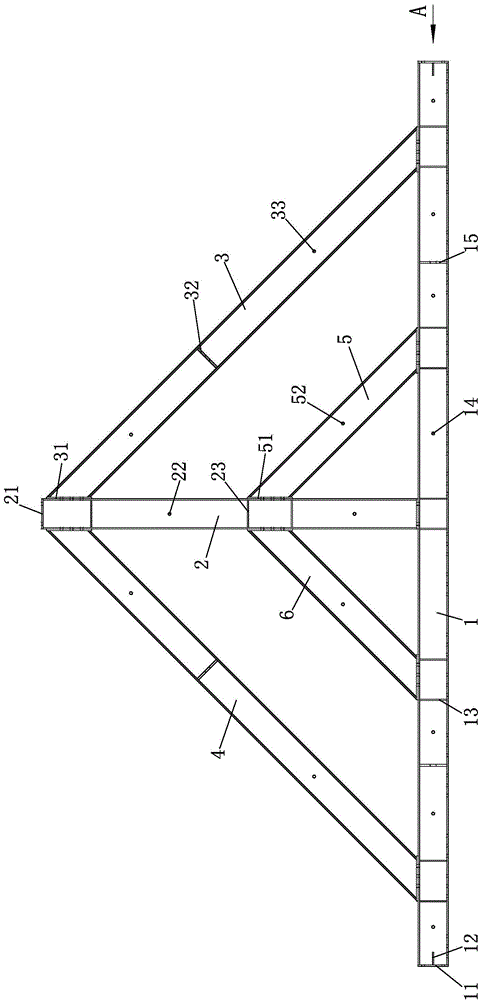

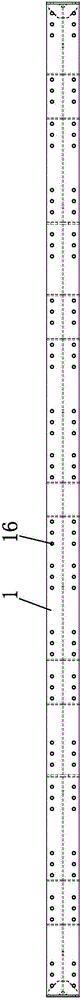

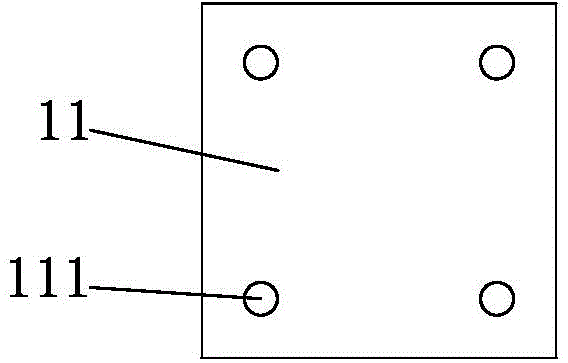

[0015] like figure 1 The purlin part shown includes the lower string beam 1 made of H-shaped steel, the web bar 2, the first diagonal braces 3, 4 and the second diagonal braces 5, 6, and the two ends of the H-shaped steel of the lower string beam 1 are transverse Cut and welded with a square flange plate A11, such as image 3 As shown, there are four flange holes A111 on the square flange plate A11, and the four flange holes A111 are distributed in a square shape, and the grooves on both sides of the H-shaped steel of the lower string beam 1 are provided with flange reinforcements. The gusset 12 and the flange reinforced gusset 12 are respectively perpendicular to the web of the H-shaped steel of the square flange A11 and the lower string beam 1 and are welded and fixed, and the grooves on both sides of the H-shaped steel of the lower string beam 1 are provided with multiple A reinforcement plate A13 and at least two lug plates A15, the reinforcement plate A13 is respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com