The supporting transfer part of the internal support system of the foundation pit support

A foundation pit support and support system technology, applied in the direction of infrastructure engineering, excavation, construction, etc., can solve the problems of non-reusable, low support rigidity, no connection, etc., to save construction costs, large construction space, The effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

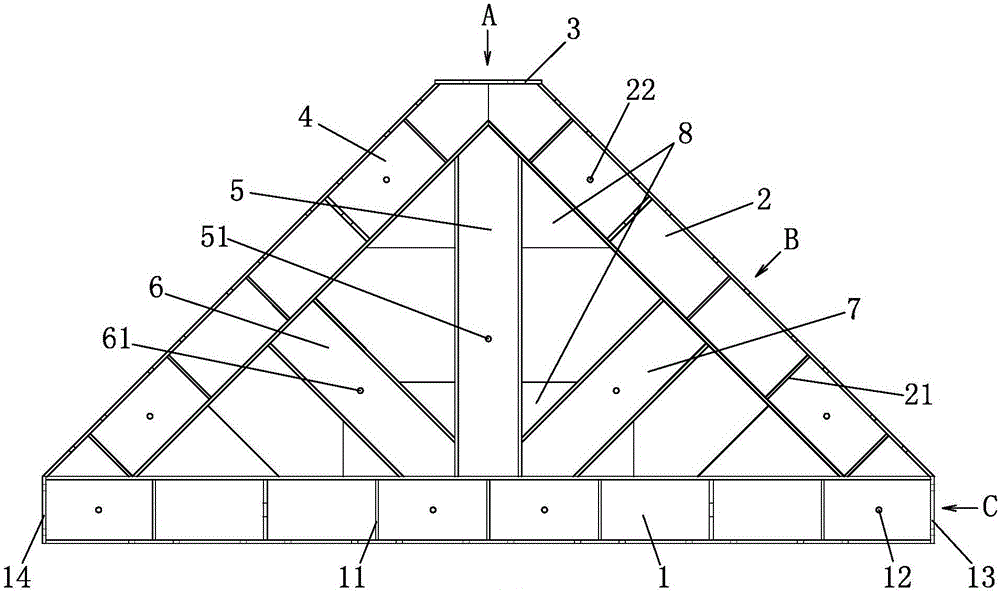

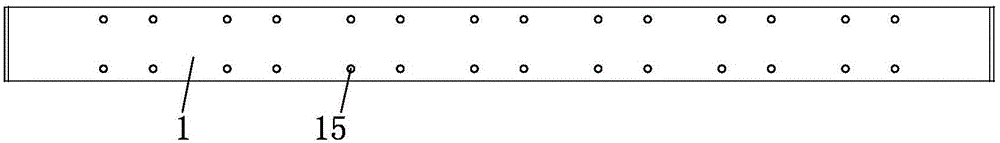

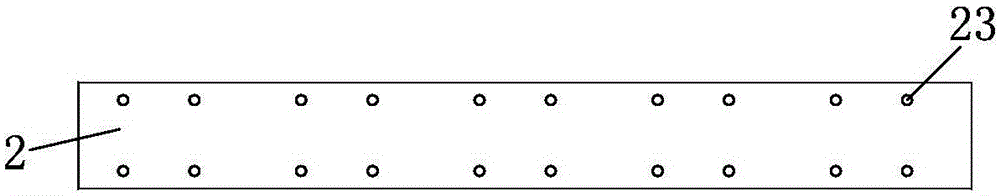

[0015] Such as figure 1 The supporting transfer parts of the foundation pit support internal support system shown include the bottom part 1 made of H-shaped steel, the first right-angle part 2, the second right-angle part 4, the bottom support 5, the first right-angle The side support 7 and the second right-angle support 6, the bottom part 1, the first right-angle part 2 and the second right-angle part 4 form an isosceles right triangle structure and are fixed by welding, and one end of the bottom support 5 is connected to The bottom part 1 is welded and fixed vertically, the other end of the bottom support part 5 is welded and fixed with the angle between the first right-angle part 2 and the second right-angle part 4, and one end of the first right-angle support part 7 is connected to the first right-angle The side part 2 is welded and fixed vertically, the other end of the first right-angle side support part 7 is welded and fixed with one side of the bottom side support part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com