Caisson with pile holes and mounting method of caisson

An installation method and caisson technology, applied in caisson, construction, infrastructure engineering and other directions, can solve the problems of high cost, difficult construction, long construction period, etc., and achieve the effect of reducing cost, reducing construction difficulty and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The installation method of the caisson with pile hole of the present invention, comprises the following steps:

[0027] Step one, leveling the foundation bed of the seated caisson.

[0028] Whether it is installed in a hard foundation area with sufficient bearing capacity or in a soft ground area with low bearing capacity, the installation place needs to be leveled, which is basically the same as the leveling of the traditional caisson bed , which will not be described in detail here. When placing a caisson with pile holes in a soft foundation area, it is necessary to dig out the silt layer to reach the secondary bearing layer or compact it so that it has a certain bearing capacity.

[0029] Step 2: After prefabricating the caisson with pile holes of the present invention, it is transported to the placement site, and is seated on the leveled foundation bed of Step 1.

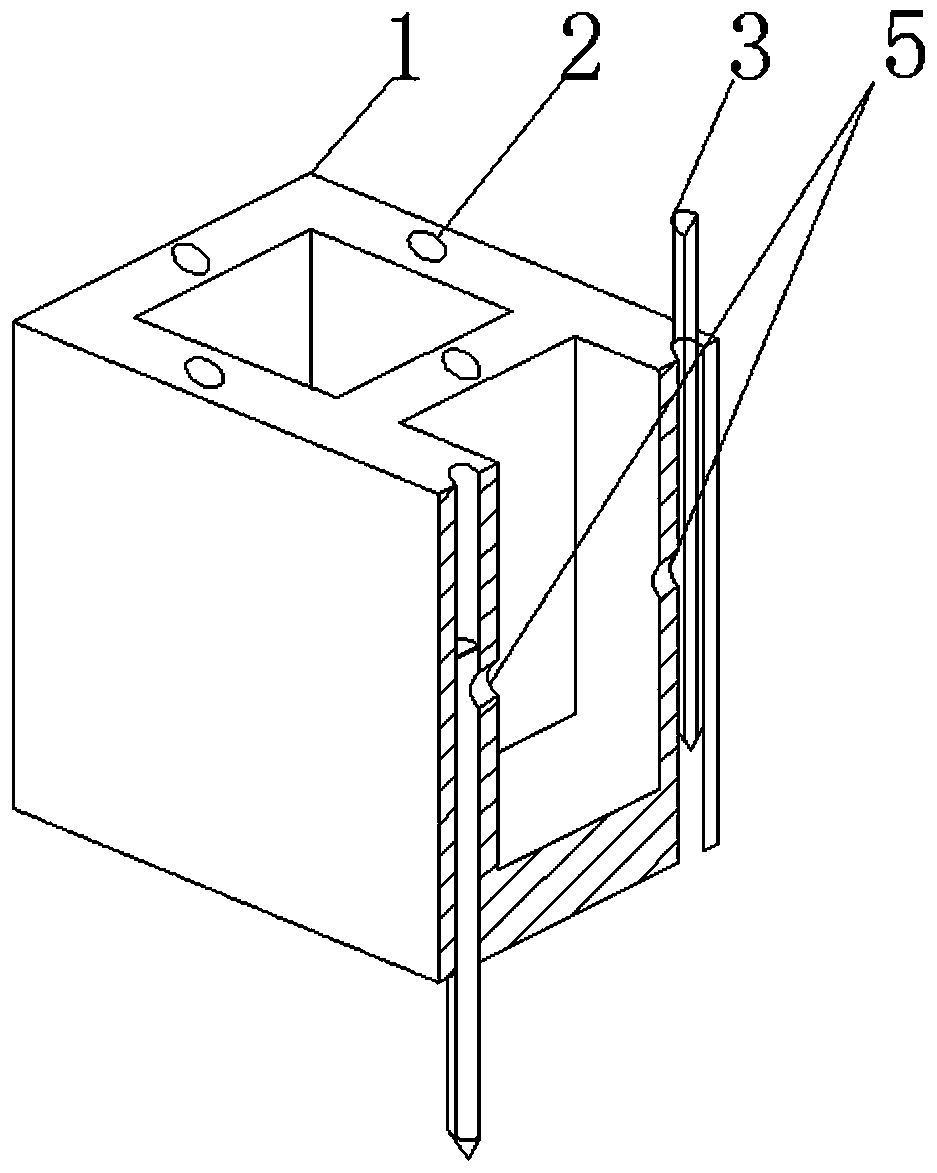

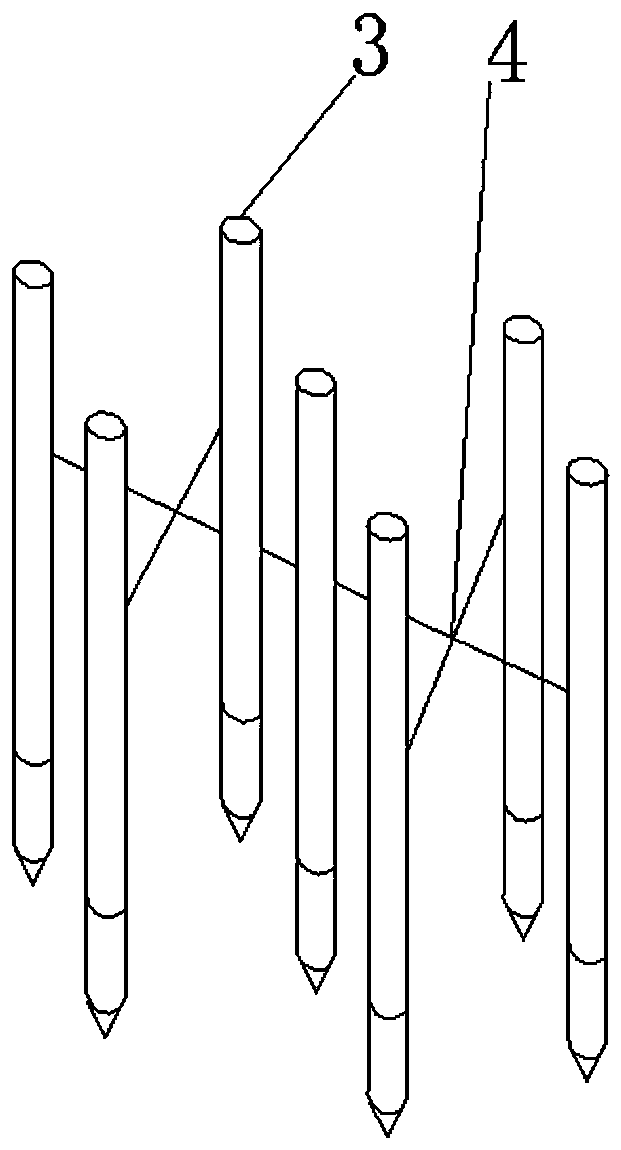

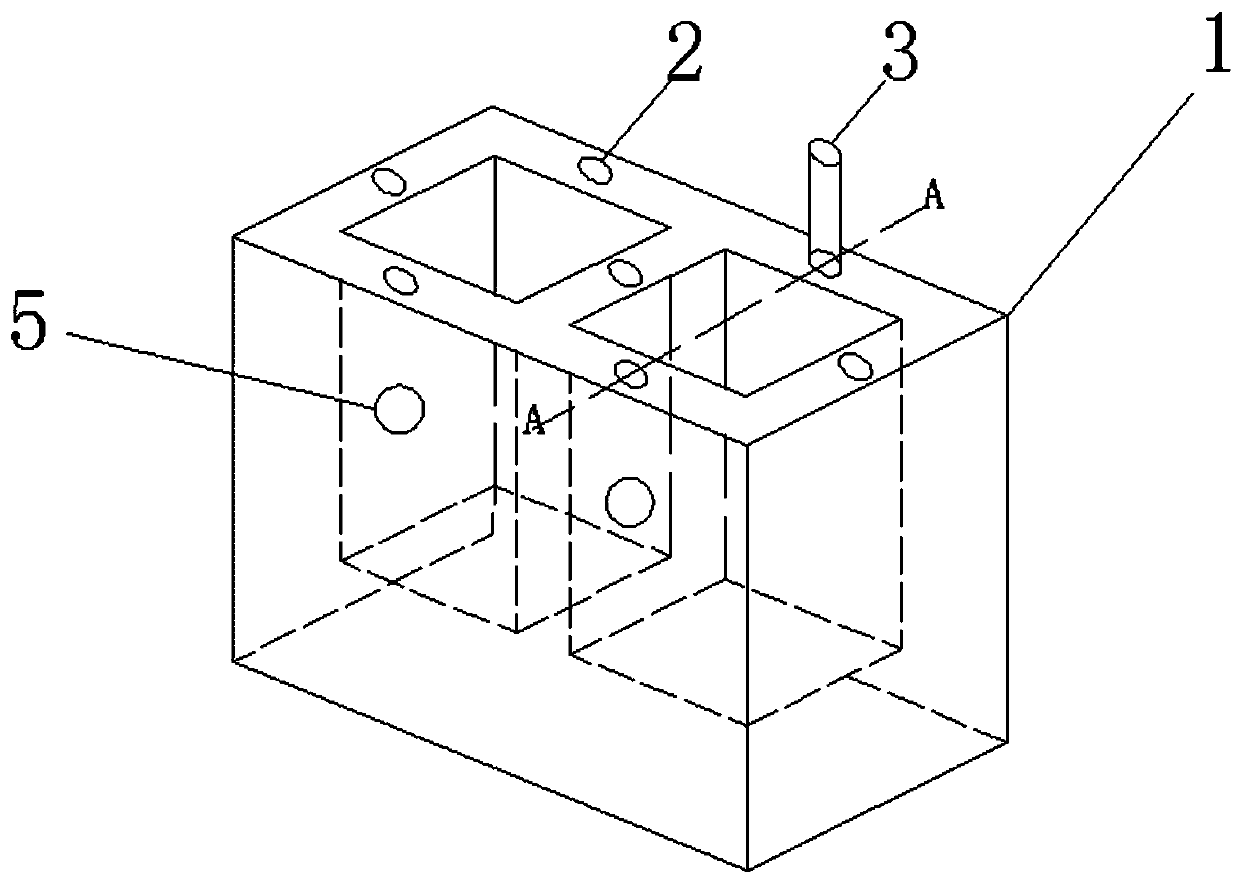

[0030] When prefabricating a caisson with pile holes, it is necessary to reserve a designed number o...

Embodiment 2

[0037] Step 1: Level the foundation bed on which the caisson is placed, and its flatness is less than 20cm. No matter in the area of hard foundation with sufficient bearing capacity or the area of soft foundation with low bearing capacity, it is necessary to level the foundation bed and ensure that the bearing capacity of the foundation is greater than the pressure of the caisson. For example, the bearing capacity of the foundation is 280kPa, and the caisson If the pressure is 220kPa, it meets the placement requirements. This is basically the same as the traditional caisson placement method, so too many explanations will not be given.

[0038] Step 2. Prefabricate a 200,000-ton A-type caisson with pile holes according to the current standard specification. The length × width × height of the caisson body is 17.7m×16.4m×23.3m, the weight is 2835t, and the caisson is stable in floating The draft is 14.0m, the inclination height is 22cm, and one pile hole is reserved on each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com