A fish-belly beam component of an internal support system for foundation pit support

A technology of support system and foundation pit support, which is used in infrastructure engineering, excavation, construction, etc., can solve the problems of no standardized connection size, cannot be reused, low support stiffness, etc., to facilitate disassembly and transportation, save money Construction cost, effect of large construction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

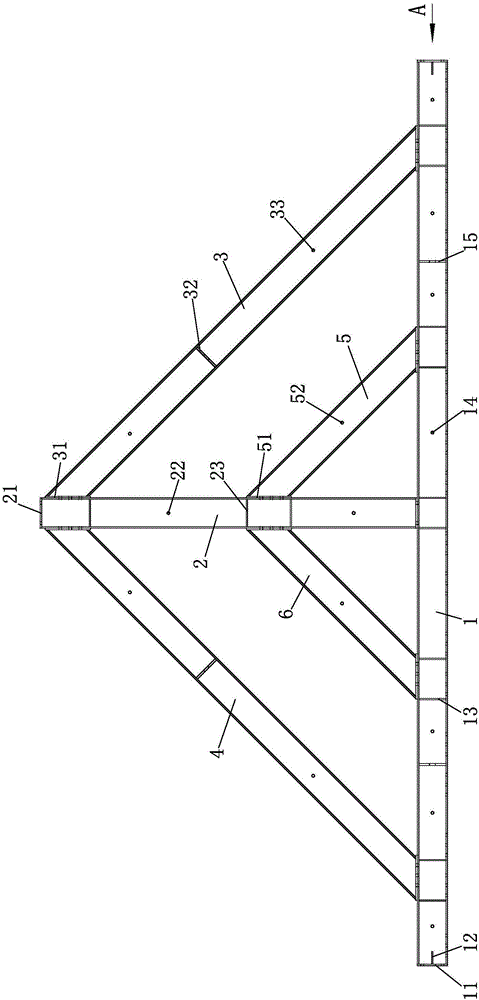

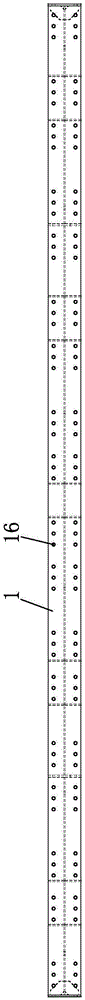

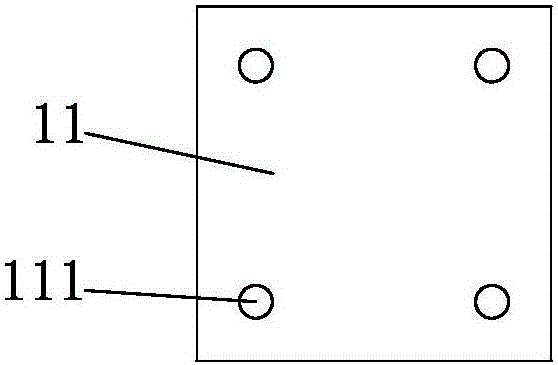

[0013] Such as figure 1 The fish-belly girder part of a foundation pit support internal support system shown includes a lower chord part 1 made of H-shaped steel, a web part 2, a first brace part 3, 4 and a second brace part 5, 6. The two ends of the H-shaped steel of the lower chord part 1 are cross-sections and are welded and fixed with a square flange plate A11, such as image 3 As shown, there are four flange holes A111 on the square flange plate A11, and the four flange holes A111 are distributed in a square shape. 200mm, the diameter of the flange hole A111 is 28mm, the grooves on both sides of the H-shaped steel of the lower chord part 1 are provided with flange reinforcement gussets 12, and the flange reinforcement gussets 12 are respectively connected to the square The flange plate A11 and the web of the H-shaped steel of the lower chord part 1 are vertically welded and fixed, and the grooves on both sides of the H-shaped steel of the lower chord part 1 are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com