Precast box beam steel reinforcement cage jig

A technology for steel cages and tire molds, applied in the manufacture of tools, ceramic molding machines, etc., can solve the problems of low production efficiency and unguaranteed quality, and achieve the effects of convenient operation, simple production, and reduced labor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

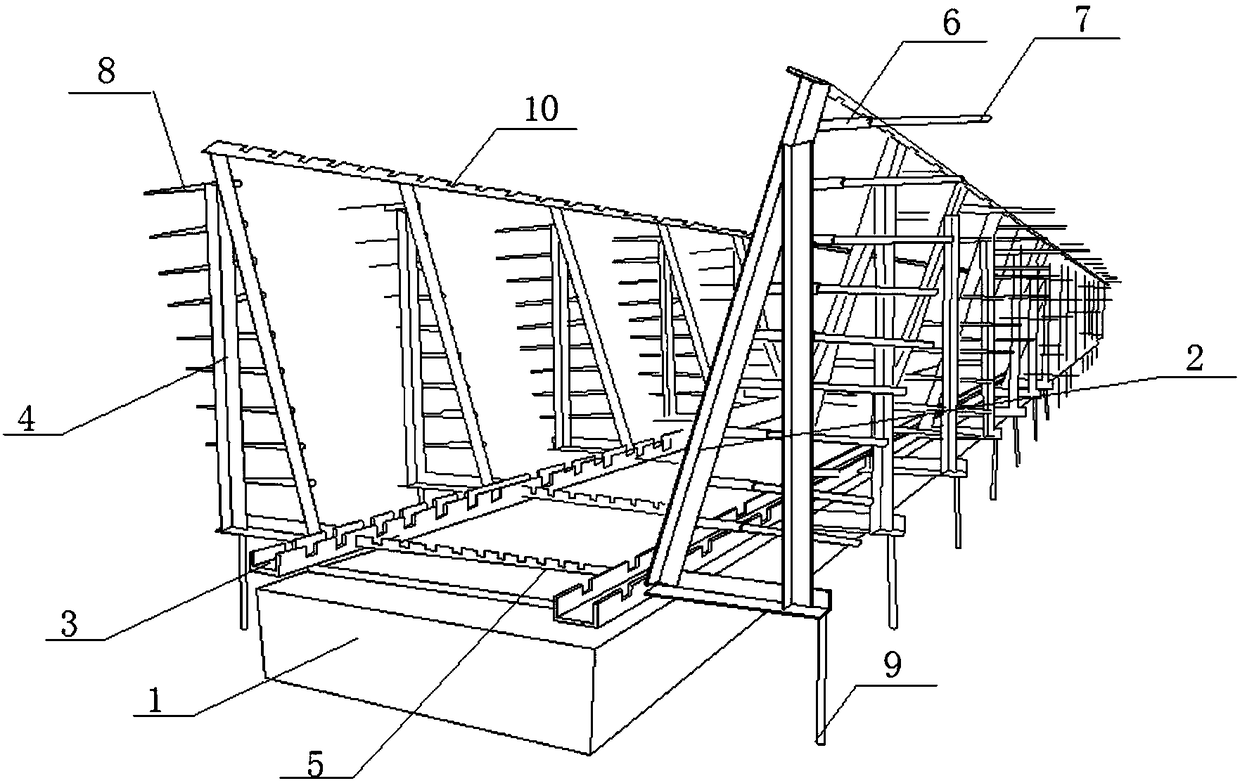

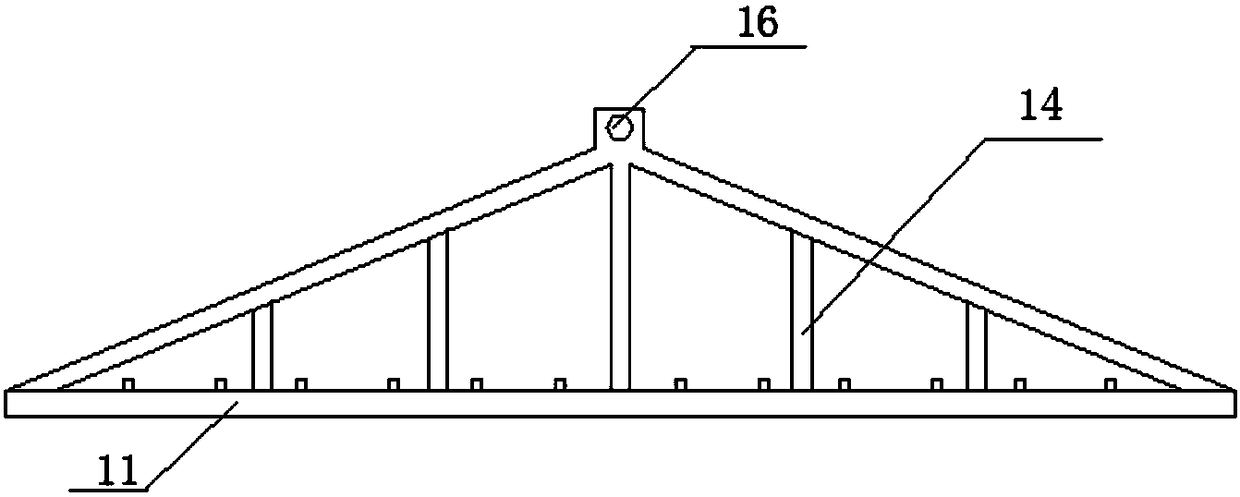

[0027] as attached figure 1 , attached figure 2 As shown, a kind of prefabricated box girder reinforcement cage tire described in this embodiment is made up of reinforcement cage mold and hanger;

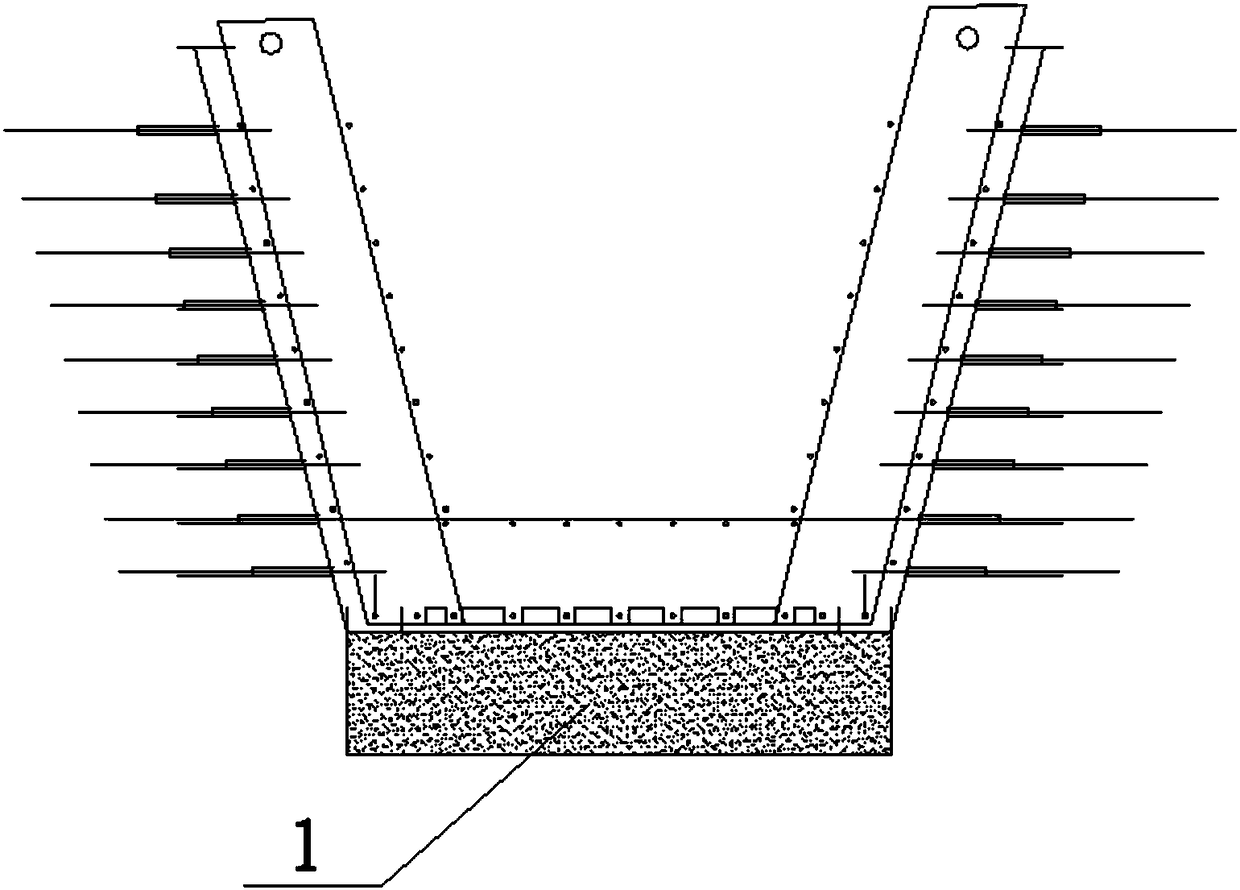

[0028] The steel cage mold includes a concrete pedestal 1 and a mold frame body 2; the mold frame body 2 is fixed on the pedestal 1; the mold frame body 2 includes four mold longitudinal beams 3 and several triangular fixing frames 4 , several mold beams 5; the two mold beams 3 are arranged on both sides of the upper surface of the concrete pedestal 1, and the mold beams 5 are evenly arranged between the two mold beams 3 in sequence; A triangular mount 4 is evenly arranged on the outside of the two mold longitudinal beams 3 successively, and one end of the bottom of the triangular mount is fixed to the outside of the mold longitudinal beam 3; The tops of the triangular mounts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com