Clamping storage device for kits

A technology for storage devices and kits, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of unsuitable kits, cumbersome push and push operations, etc., and achieve the effect of convenient and automatic access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0029] The fixed connection mentioned in this device refers to fixing by means of welding, screw fixing, etc., and different fixing methods are used in combination with different use environments. The sliding connection described is all connected by sliding the slider in the chute .

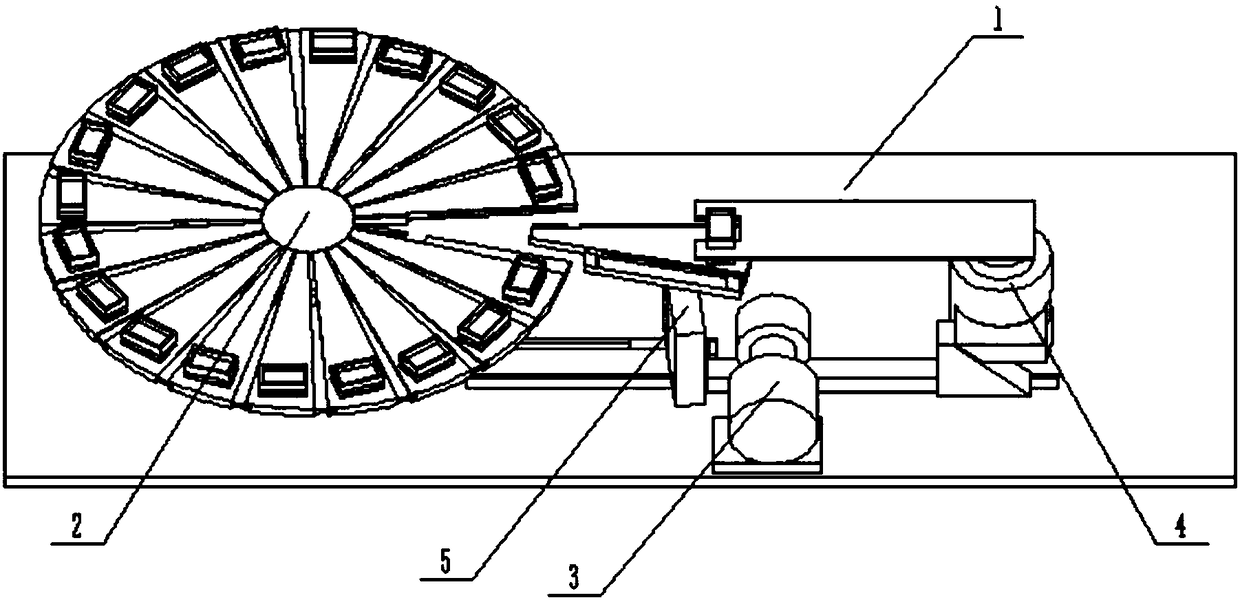

[0030] Such as Figure 1 to Figure 12As shown, a clamping storage device for a reagent box includes a base slide 1, a storage device 2, a driving device 3, a rotating clamping device 4 and a moving delivery device 5, and the storage device 2 is fixedly connected to the base slide 1 Above, the upper end of the mobile delivery device 5 is slidably connected to the storage device 2, the lower end of the mobile delivery device 5 is slidably connected to the base slide 1, the rotary clamping device 4 is fixedly connected to the base slide 1, and the left end of the rotary clamping device 4 The gap fits in the driving device 3 , the right end of the driving device 3 fits with the rotary clamping devic...

specific Embodiment approach 2

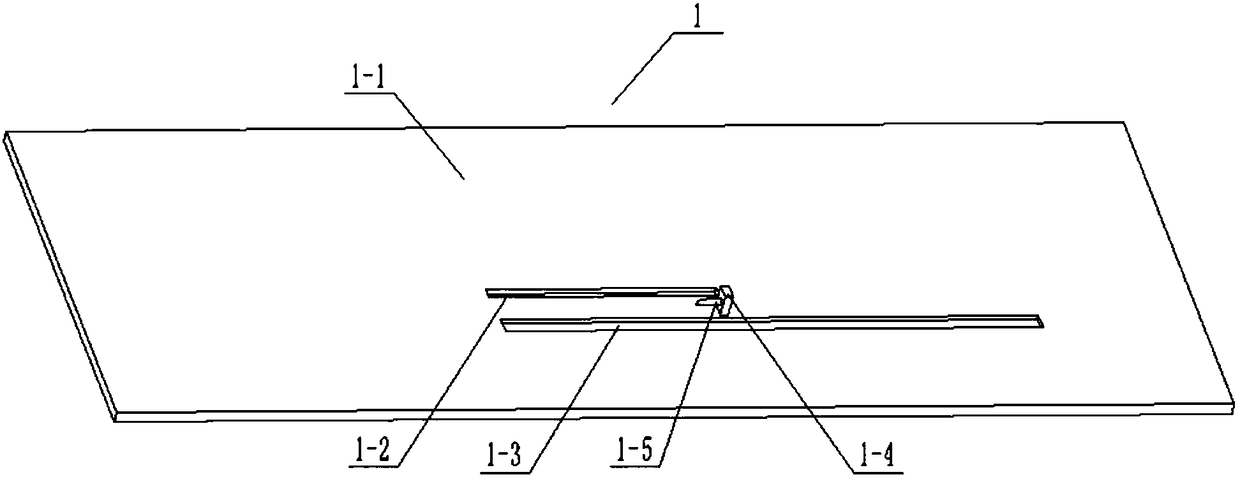

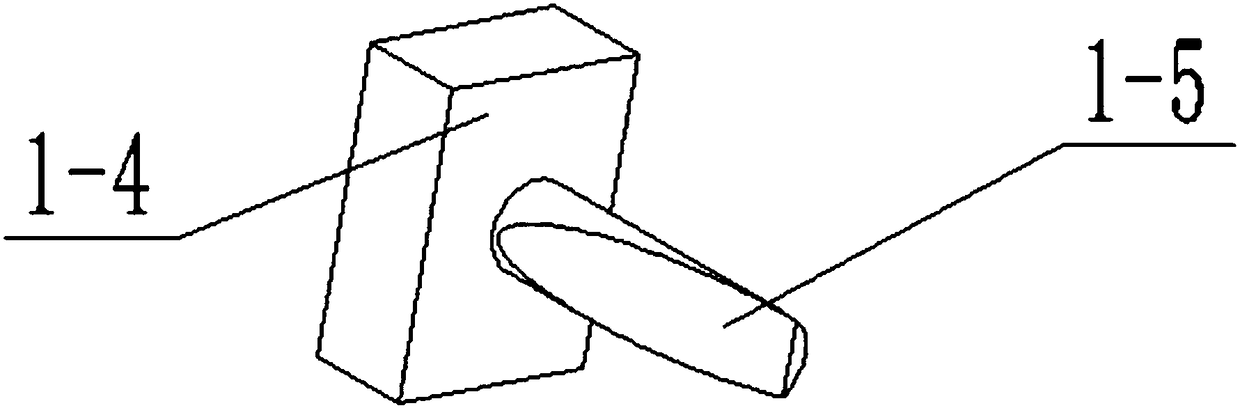

[0031] Such as Figure 1 to Figure 12 As shown, this embodiment will further describe Embodiment 1. The base slide 1 includes a base plate 1-1, a moving feeding device chute 1-2, a rack chute 1-3, a support plate 1-4 and a socket The shaft 1-5, the mobile feeder chute 1-2 and the rack chute 1-3 are all arranged on the base plate 1-1, the support plate 1-4 is fixedly connected on the base plate 1-1, and the support plate 1-4 It is arranged between the mobile delivery device chute 1-2 and the rack chute 1-3, the right end of the insertion shaft 1-5 is fixedly connected to the support plate 1-4, and the left end surface of the insertion shaft 1-5 is an inclined plane.

specific Embodiment approach 3

[0032] Such as Figure 1 to Figure 12 As shown, this embodiment will further illustrate Embodiment 2. The storage device 2 includes a rotating and fixing device 2-1, a moving plate 2-2, a reagent box moving storage box 2-3, a left chute 2-4, Right chute 2-5, large fixed groove 2-6 and small fixed groove 2-7, mobile plate 2-2 are provided with a plurality of, mutually slidingly connect between a plurality of mobile plates 2-2, all mobile plates 2-2 2 are all slidably connected on the rotating fixing device 2-1, and the upper end of each moving plate 2-2 is provided with a large fixing groove 2-6, and each large fixing groove 2-6 is provided with a small fixing groove 2-7 , each large fixed groove 2-6 is equipped with a reagent box mobile storage box 2-3 with gaps, and the left and right sides of the lower end of each mobile plate 2-2 are provided with a left chute 2-4 and a right chute 2-5, the front end and rear end of each mobile plate 2-2 are provided with a displacement sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com