A Hollow Glass Aluminum Frame Corrector and Its Application Method

A calibrator and glass technology, applied in the field of hollow glass aluminum frame calibrator, can solve problems such as poor sealing performance of insulating glass, lack of unified standards and specifications, etc. dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

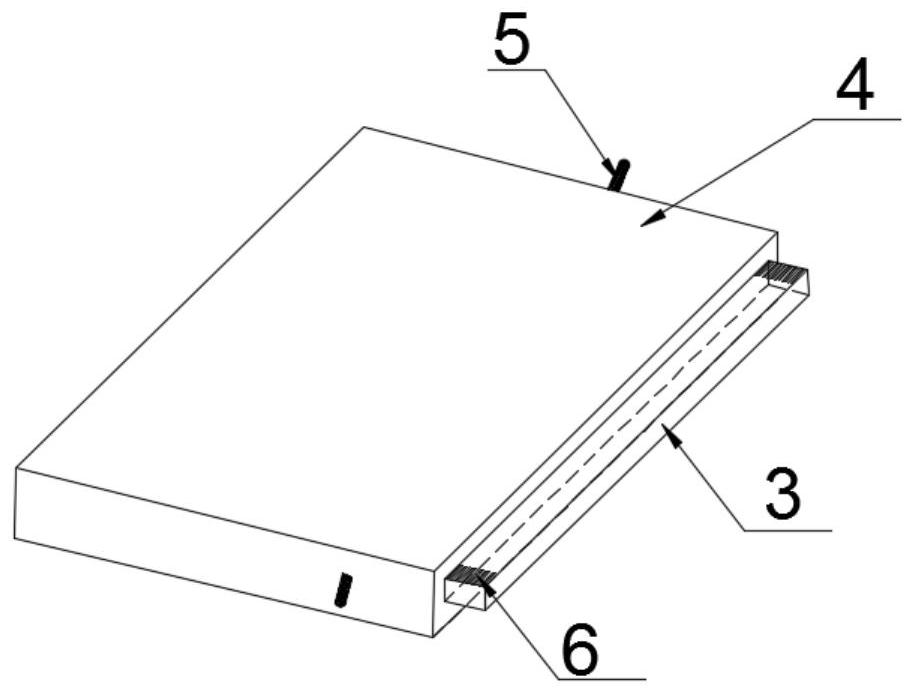

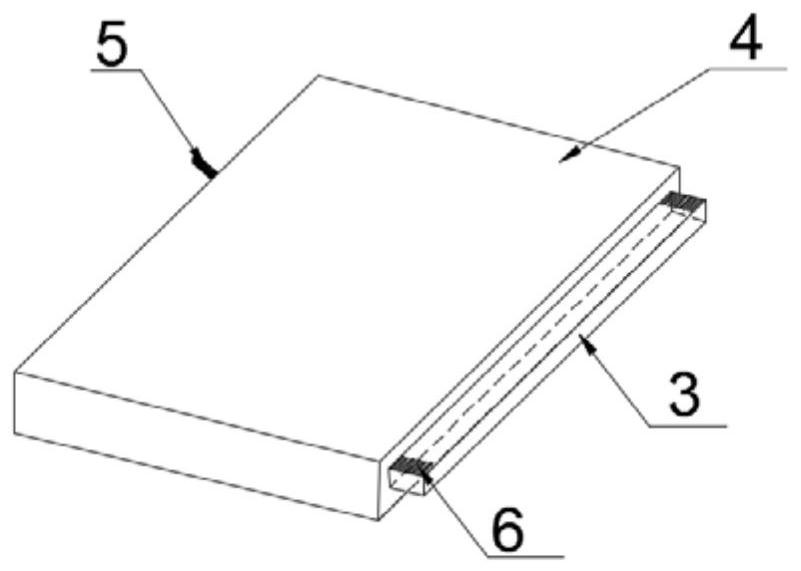

[0053] The locking part 5 is a first bolt, and the first bolt is arranged on the supporting part 4, and the vertical plate or the side plate of the supporting part 4 is provided with a through bolt hole, and the first bolt passes through the bolt hole and contacts with the positioning part 3, The tightness between the positioning part 3 and the supporting part 4 is determined by adjusting the extrusion degree between the first bolt and the positioning part 3 .

Embodiment 2

[0055] The locking part 5 is a second stud, and the second stud is arranged on the support part 4, and the vertical plate or the side plate of the support part 4 is provided with a through first threaded hole, and the stud passes through the first threaded hole, and is connected with the first threaded hole. The positioning part 3 is in contact, and the degree of tightness between the positioning part 3 and the supporting part 4 is determined by adjusting the extrusion degree between the second stud and the positioning part 3 .

Embodiment 3

[0057] The difference between this embodiment 3 and embodiment 1, embodiment 2 is:

[0058] The locking part 5 is configured as a second bolt or a second stud.

[0059] The support part 4 is provided with a bottom plate, the bottom plate is perpendicular to the vertical plate and the side plate, and is connected with the vertical plate and the side plate;

[0060] A second threaded hole is provided at the center of the bottom plate, and a third threaded hole on the same axis as the second threaded hole is provided on the positioning portion 3 .

[0061] The second threaded hole and the third threaded hole are matched with a second bolt or a second stud, and the positional relationship between the positioning part 3 and the support part 4 can be adjusted by adjusting the positional relationship between the second bolt or the second stud and the second threaded hole. distance between.

[0062] A method for using a hollow glass aluminum frame calibrator, comprising:

[0063] a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com