Highway speed bump

A technology of speed bumps and roads, which is applied in the field of municipal engineering, can solve the problems of large vibration force, single structure of speed bumps, and large impact, and achieve the effect of resisting vehicle impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

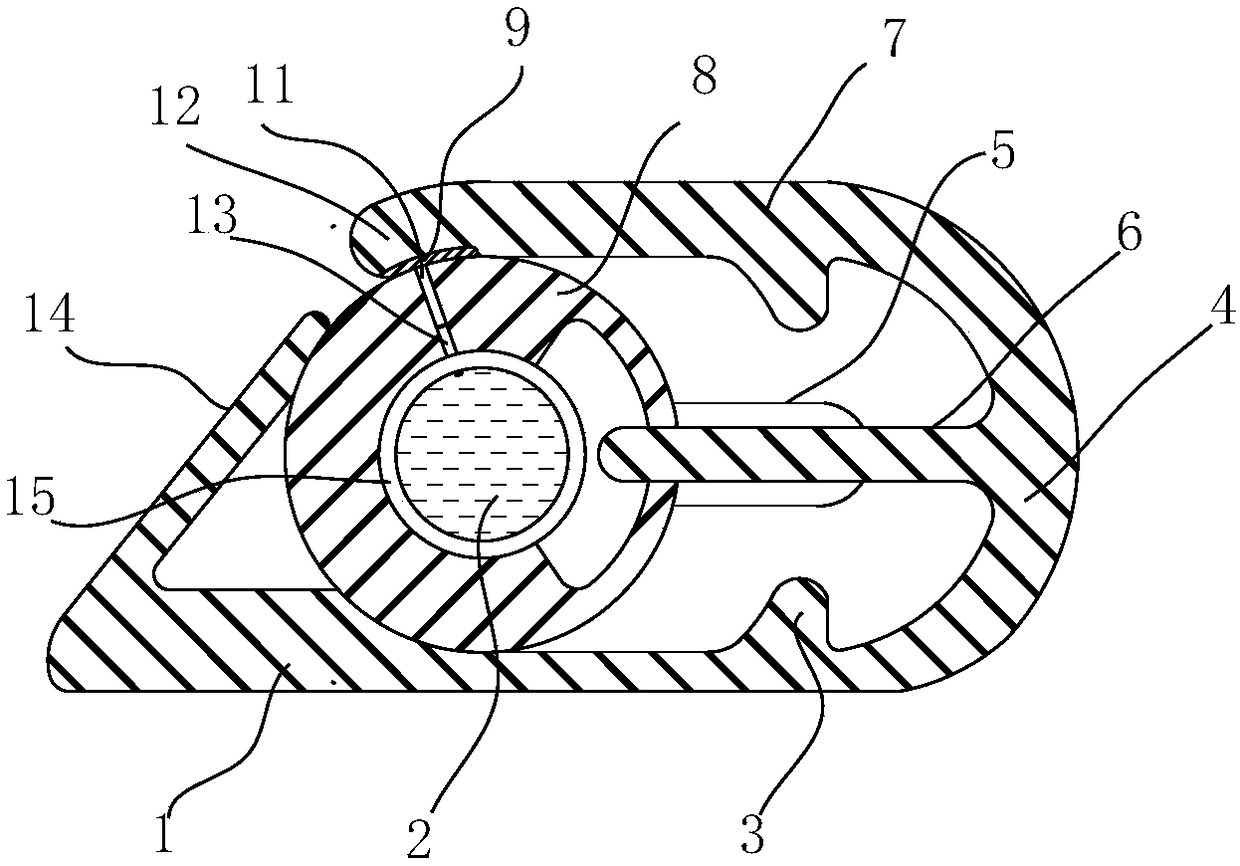

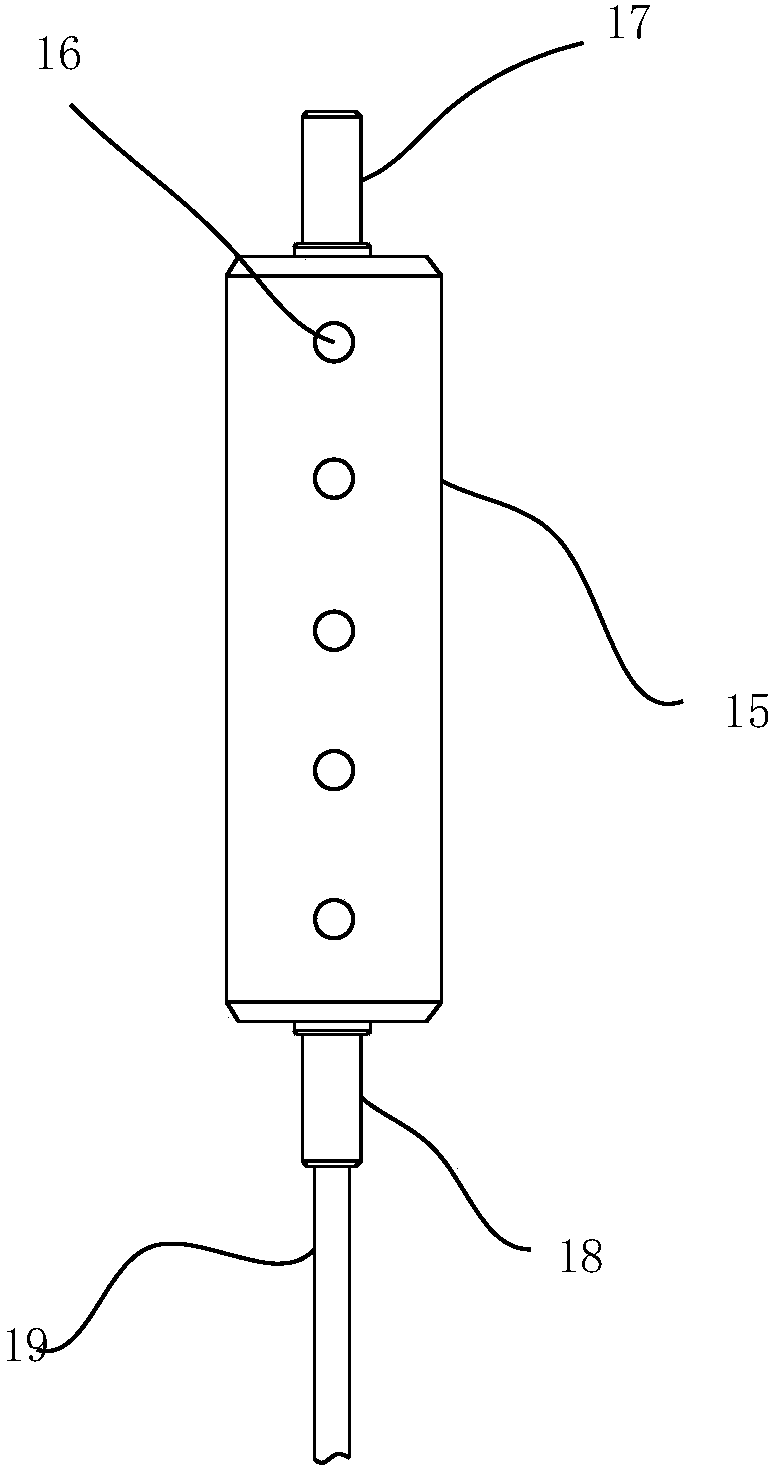

[0015] Such as figure 1 and figure 2 As shown, a road deceleration belt includes a deceleration belt main body, the deceleration belt main body is made of steel, and its bottom surface is locked and installed on the ground by more than one screw;

[0016] In this embodiment, the main body of the deceleration belt includes a top plate 7, a bottom plate 1, and an arc-shaped connecting section 4. The front and rear ends of the main body of the deceleration belt are sealed, and the arc-shaped connecting section 4 connects the top plate 7 and the bottom plate 1. Installation cavity, a circular support 8 is installed in the installation cavity, the circular support 8 is as long as the entire deceleration belt main body, the upper end of the circular support 8 is in contact with the lower end of the top plate 7, and the lower end of the circular support 8 is in contact with the bottom plate 1, the outer end of the top plate 7 is provided with an arc-shaped hook portion 12, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com