Fixed intelligent dust suppression system for coal transportation train

A stationary, train technology, applied in the direction of removing smoke and dust, using liquid separating agent, cleaning methods and utensils, etc., can solve the problems of waste of water resources, inability to adjust, and dead corners in single-row sprinkler watering, saving water resources, The effect of avoiding water waste and facilitating maintenance and repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

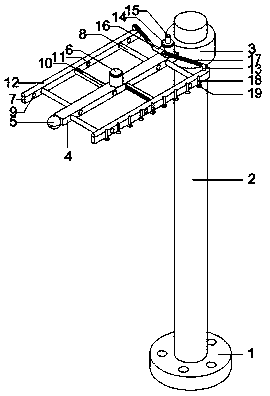

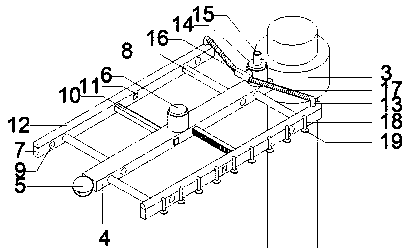

[0014] Such as figure 1 with figure 2 As shown, a fixed intelligent dust suppression system for coal transport trains includes a base 1, a pillar 2, a connecting ring 3, a cross arm 4, a probe 5, a motor 6, a support arm 7, a connecting rod 8, and a through hole 9 , linkage rod 10, through groove 11, water tank 12, elbow 13, booster pump 14, water inlet pipe 15, tee pipe 16, flexible pipe 17, branch pipe 18, nozzle 19, it is characterized in that: described pillar 2 The bottom end is welded on the base, and the top end is welded with a connection ring 3, one end of the cross arm 4 is connected to the outer wall of the connection ring 3, and the other end is installed with a probe 5 through a screw, and the motor 6 is installed in the middle of the cross arm 4. Two through-holes 9 are drilled on the left and right sides of the arm 4, and two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com