Building waste grinding and separating equipment and separating method

A construction waste and separation equipment technology, applied in the field of construction equipment, can solve problems such as environmental pollution, poor separation effect, and difficult cooling of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

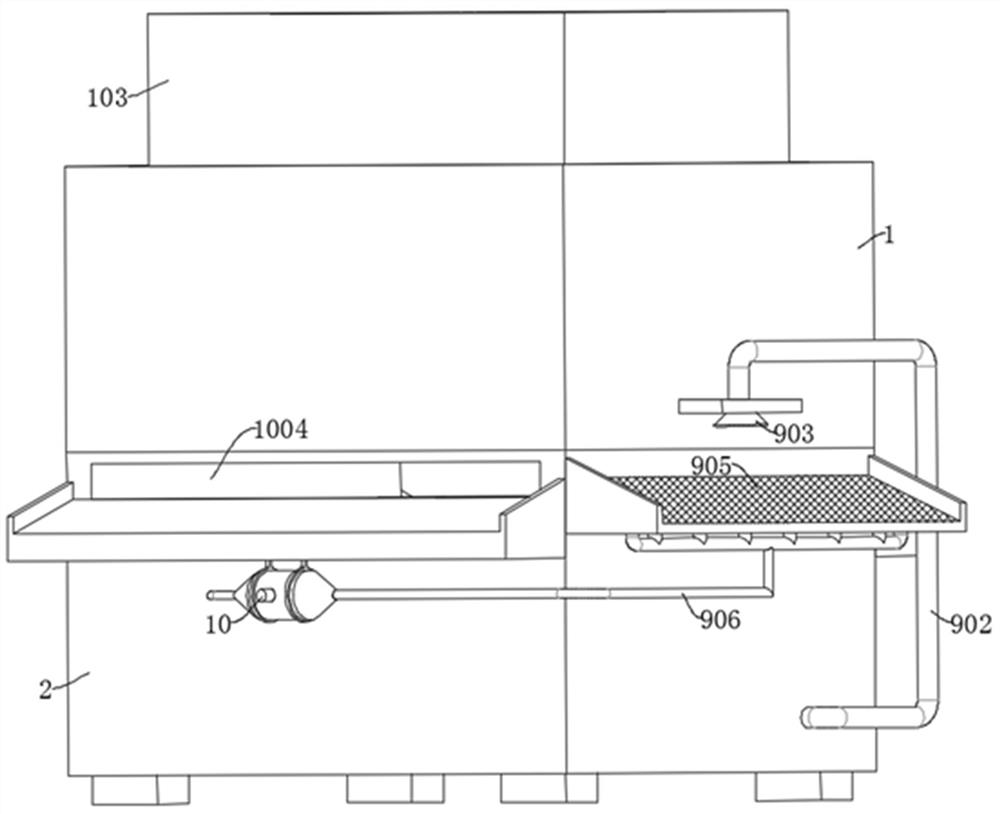

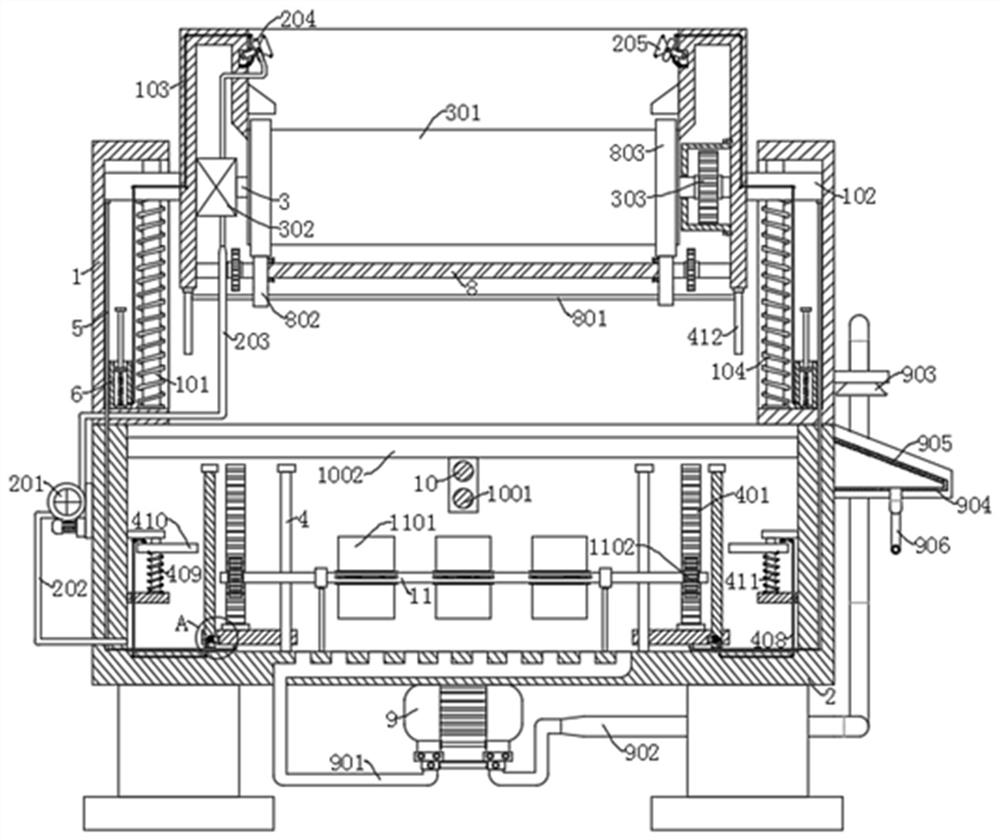

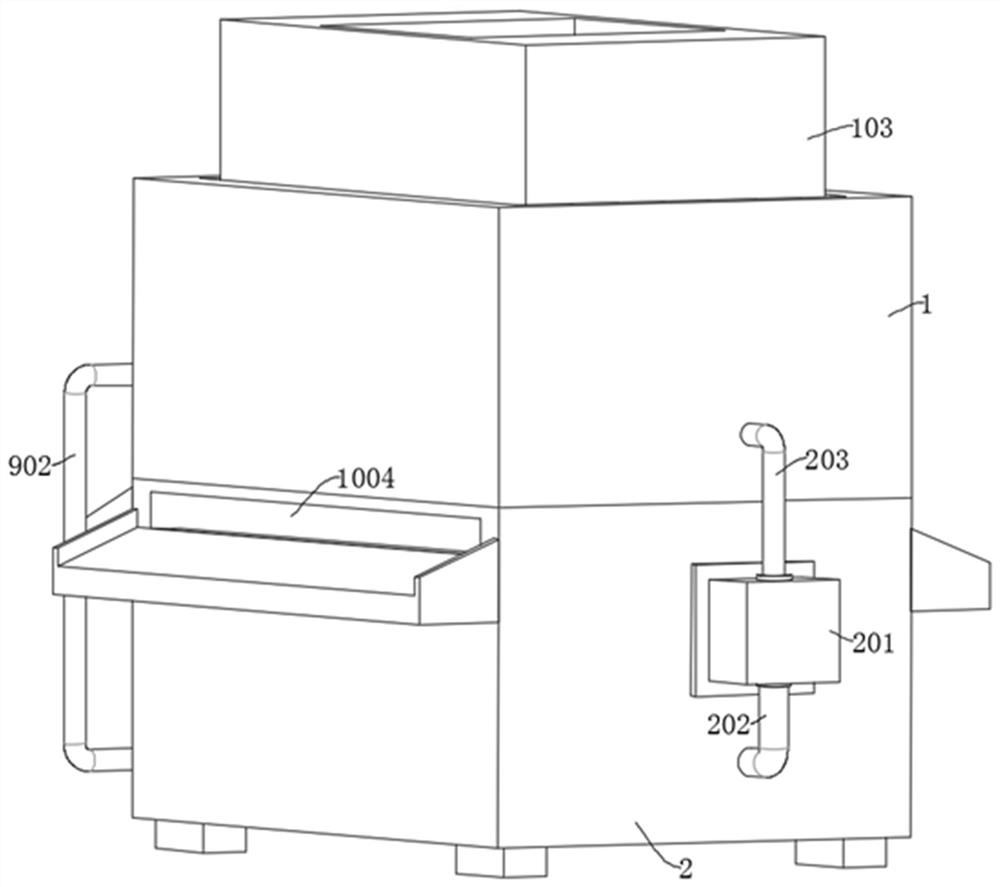

[0043] refer to Figure 1-Figure 11 , a construction waste grinding and separating equipment, including a box 1, and also includes: a water tank 2 fixedly connected to the bottom of the box 1, the top of the water tank 2 communicates with the bottom of the box 1; a processing box 103, slidably connected to the top of the box 1 , wherein, the processing box 103 is provided with a grinding mechanism for grinding and crushing construction waste, and a spring 104 is arranged between the processing box 103 and the inner wall of the bottom of the box 1; the mounting seat 204 is rotatably connected to the inner wall of the processing box 103; spray The water nozzle 205 is fixedly connected to the mounting seat 204, and a spring five 608 is connected between the mounting seat 204 and the processing box 103; the telescopic cylinder 605 is fixedly connected to the inner wall of the processing box 103; The second connecting seat 607 is slidably connected to the mounting seat 204 and is r...

Embodiment 2

[0048] refer to figure 2 , Figure 5 , Figure 8 , Figure 9 and Figure 11 , a construction waste grinding and separating equipment, which is basically the same as that of Embodiment 1. Further, a support column 101 is fixedly connected to the inner wall of the bottom of the box body 1, and a first connection seat 102 is slidably connected to the support column 101. The first connection seat 102 is fixedly connected to the outer wall of the processing box 103 , and the first connecting seat 102 is fixedly connected to the bottom of the flotation board 402 through the traction rope 5 .

[0049] The air supply assembly includes a piston cylinder 6 and a piston disc 601 slidably connected in the piston cylinder 6. A connecting rod 602 is fixedly connected to the piston disc 601. The piston cylinder 6 is communicated with the inner cavity of the telescopic cylinder 605 through a conduit three 604. A spring four 603 is arranged between the 6 and the piston disc 601 , and the ...

Embodiment 3

[0059] refer to figure 1 , figure 2 , Figure 4 , Image 6 and Figure 7 , a construction waste grinding and separating equipment, which is basically the same as the embodiment 1, and further, the driving component that drives the second scraper 1002 to move includes a reciprocating screw 10, and a guide rod two 1001 that is fixedly connected to the inner wall of the water tank 2, The second scraper 1002 is slidably connected to the second guide rod 1001 and is threadedly connected to the reciprocating screw 10 . The second outer wall of one end of the reciprocating screw 10 penetrating through the third pipe 906 is fixedly connected with the second impeller 1003 .

[0060] The separated concrete crushed stones settle at the bottom of the water tank 2, and the plastic garbage floats on the water surface in the water tank 2. At this time, the sand pump 9 is started, and the sand pump 9 absorbs the small concrete fragments at the bottom of the water tank 2 through the pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com