Coal mine fully mechanized coal mining face end top cutting pressure releasing device and top cutting pressure releasing method

A fully mechanized mining face, roof cutting and pressure relief technology, applied in mining equipment, surface mining, underground mining, etc., can solve problems such as high equipment failure rate and unstable roof cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

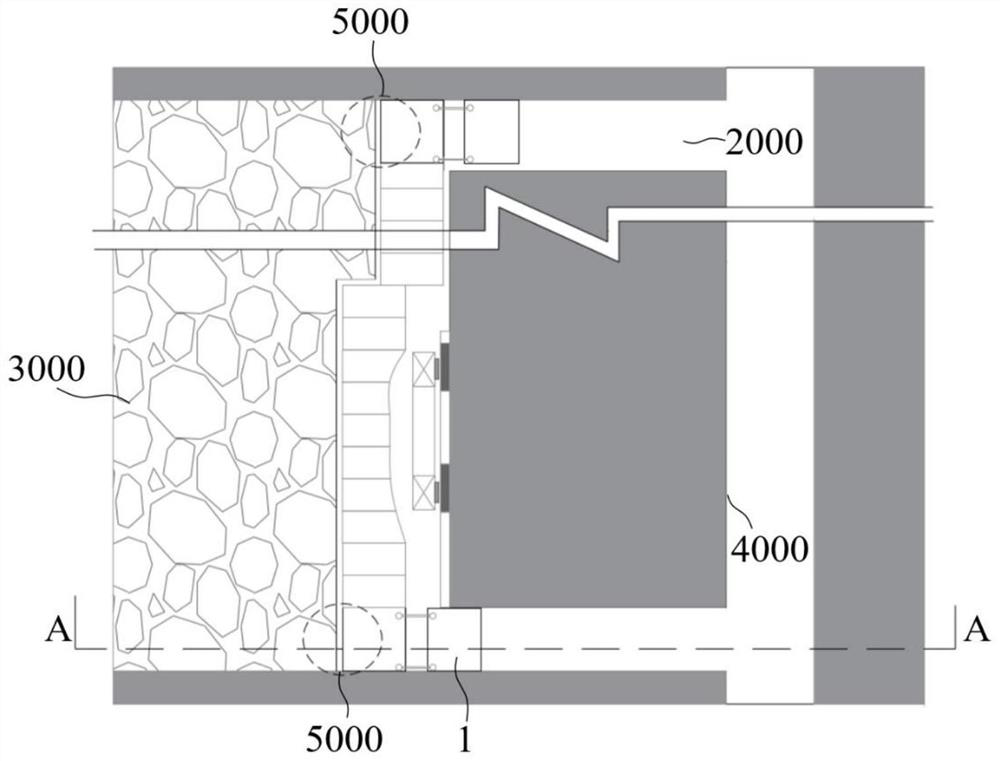

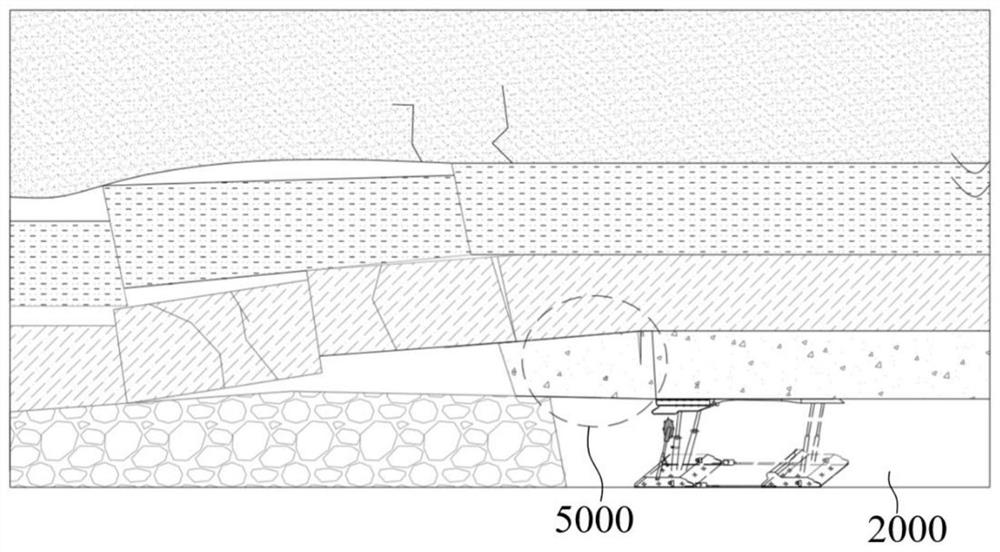

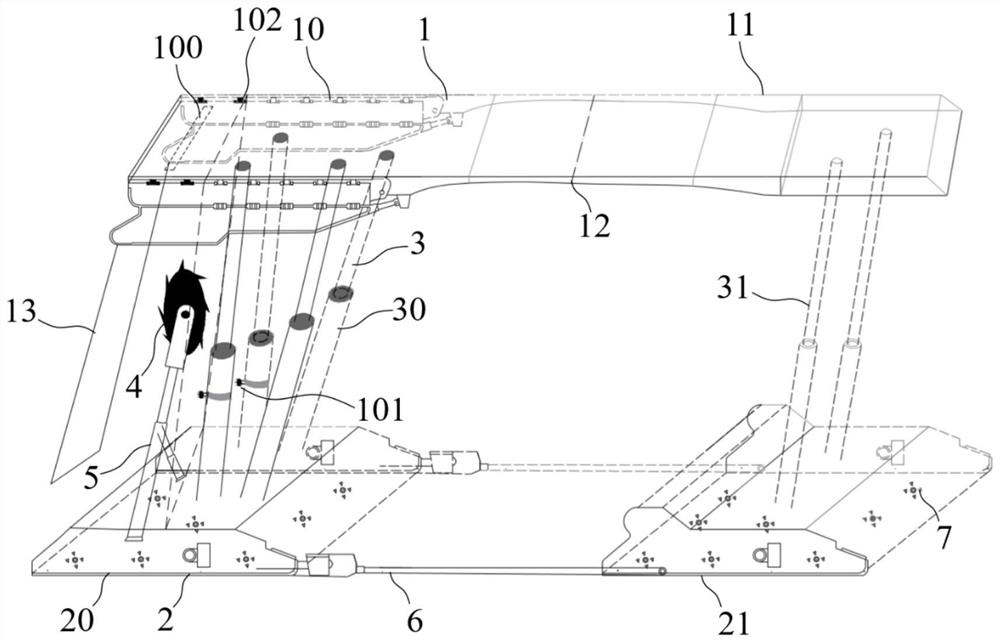

[0063] The top cutting and pressure relief equipment for the fully mechanized coal mining face of this embodiment includes:

[0064] An upper plate 1, which is composed of a main body upper plate 10 and an auxiliary body upper plate 11 connected horizontally;

[0065] The support bottom plate 2 is composed of a main body bottom plate 20 and an auxiliary body bottom plate 21 connected horizontally;

[0066] Support unit 3, which is placed between the upper plate 1 and the bottom plate 2 of the bracket, and supports the lifting movement of the upper plate 1;

[0067] Cutting unit 4, which is placed between the main body upper plate 10 and the main body bottom plate 20, the end of the main body upper plate 10 away from the auxiliary body upper plate 20 is provided with a cutting relief opening 100 along the width direction, and the working end of the cutting unit 4 passes through the cutting The relief port 100 protrudes from the upper surface of the main body upper plate 10;

...

Embodiment 2

[0075] The top-cutting and pressure-relief equipment for the fully mechanized coal mining face of this embodiment is further improved on the basis of Embodiment 1. The support unit 3 is a hydraulic column, and four main body upper plates 10 and the main body bottom plate 20 are provided with four Hydraulic column support, two hydraulic column supports are provided between the upper plate 11 of the auxiliary body and the bottom plate 21 of the auxiliary body.

[0076] Such as image 3 As shown, in this embodiment, the upper plate 1 and the support bottom plate 2 are supported by the hydraulic column, and the relative distance between the upper plate 1 and the support bottom plate 2 is controlled by the expansion and contraction of the hydraulic column, and four main body upper plate 10 and the main body bottom plate 20 are arranged. Hydraulic column support, four hydraulic columns are arranged in two rows along the length direction of the main body support plate 20, and two hyd...

Embodiment 3

[0078] The top cutting and pressure relief equipment for the fully mechanized coal mining face of this embodiment is further improved on the basis of Embodiment 2. The middle part of the hydraulic column between the main body upper plate 10 and the main body bottom plate 20 near the cutting relief port 100 is set There is a distance sensor 101 .

[0079] Such as image 3 As shown, the distance sensor 101 of this embodiment can sense the distance change between the collapsed rock mass and the equipment, so as to assist in locking the position where roof cutting and pressure relief are required. Further, the data monitored by the distance sensor 101 is matched with the working face 4000 The actual moving distance is the cutting distance of the shearer at 4000 on the working face. The combination of the two sets of data can further accurately locate the position that needs to be cut and relieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com