High-pressure and high-flow two-position four-way liquid control reversing valve

A technology of hydraulic control reversing valve and two-position four-way, which is applied in the field of hydraulic control, can solve the problems of reliability and maintainability uncertain factors, can not be applied to military projects, short closing and reversing time, etc., and the switching time can be adjusted , avoid easy stuck, smooth control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

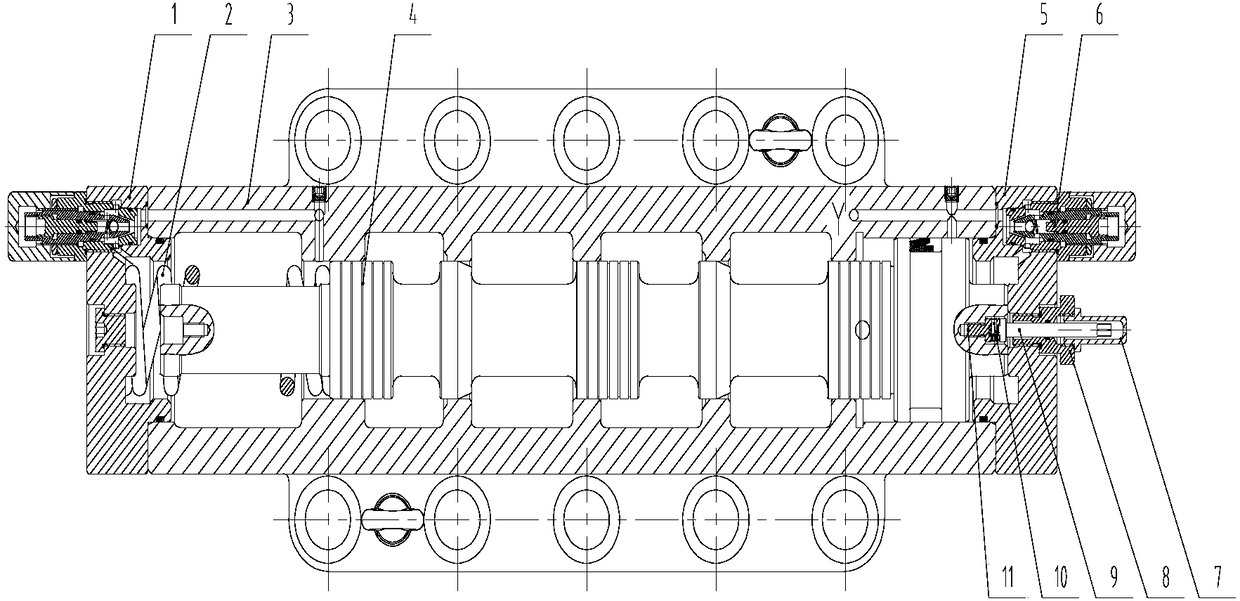

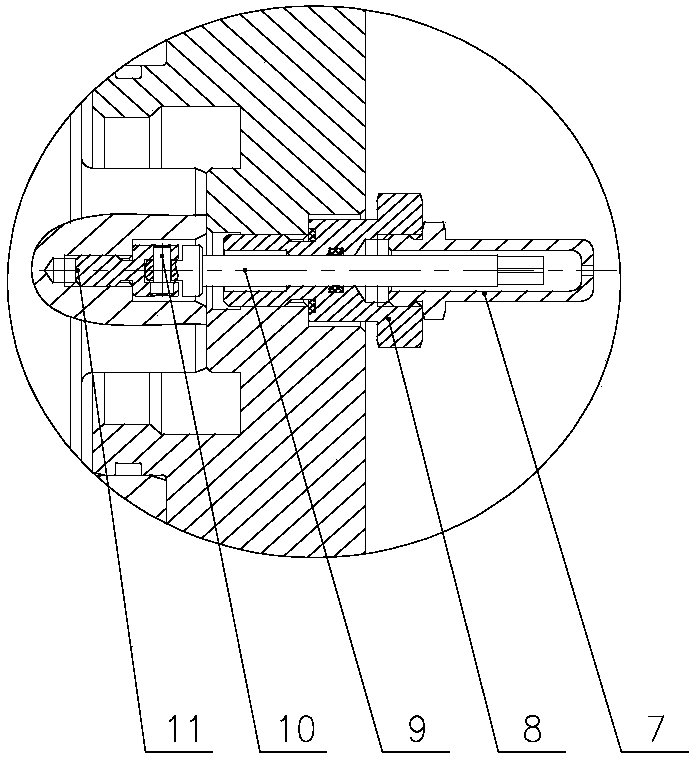

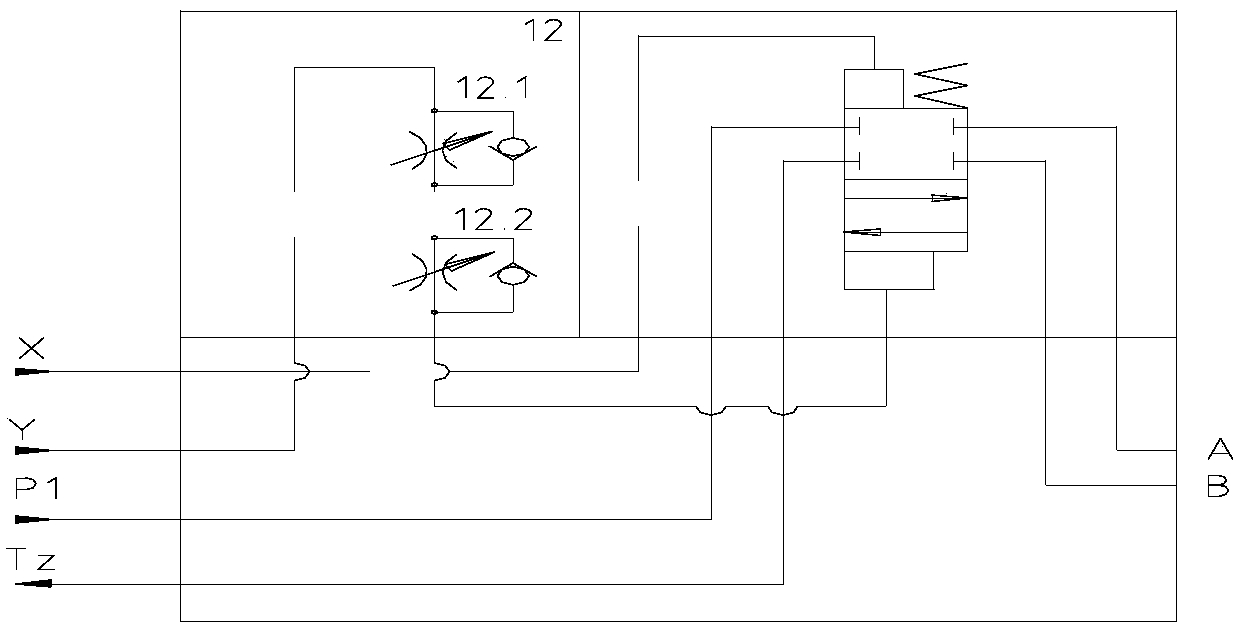

[0032] See attached figure 1 , 2 and attached image 3 , the high-pressure and large-flow two-position four-way hydraulically controlled reversing valve in this embodiment includes a left end cover 1, a return spring 2, a main valve body 3, a main valve core 4, a right end cover 5, a hydraulic buffer mechanism 6, and a protective cover 7 , Measuring sleeve 8, measuring rod 9, connecting pin 10, measuring connector 11 and speed regulating valve group 12. The speed regulating valve group 12 is composed of two speed regulating valves 12.1 and 12.2 connected in series, and is used to control the flow rate of the Y oil circuit downstream of the hydraulic control reversing valve, so as to realize the adjustment of the opening and closing switching time of the hydraulic control reversing valve valve port (The speed regulating valve group 12 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com