Detachable water bath type gasifier

A gasifier and water bath technology, applied in the field of gasifier, can solve the problems of high maintenance cost, time-consuming and laborious maintenance, difficult disassembly and assembly, and achieve the effect of offsetting the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

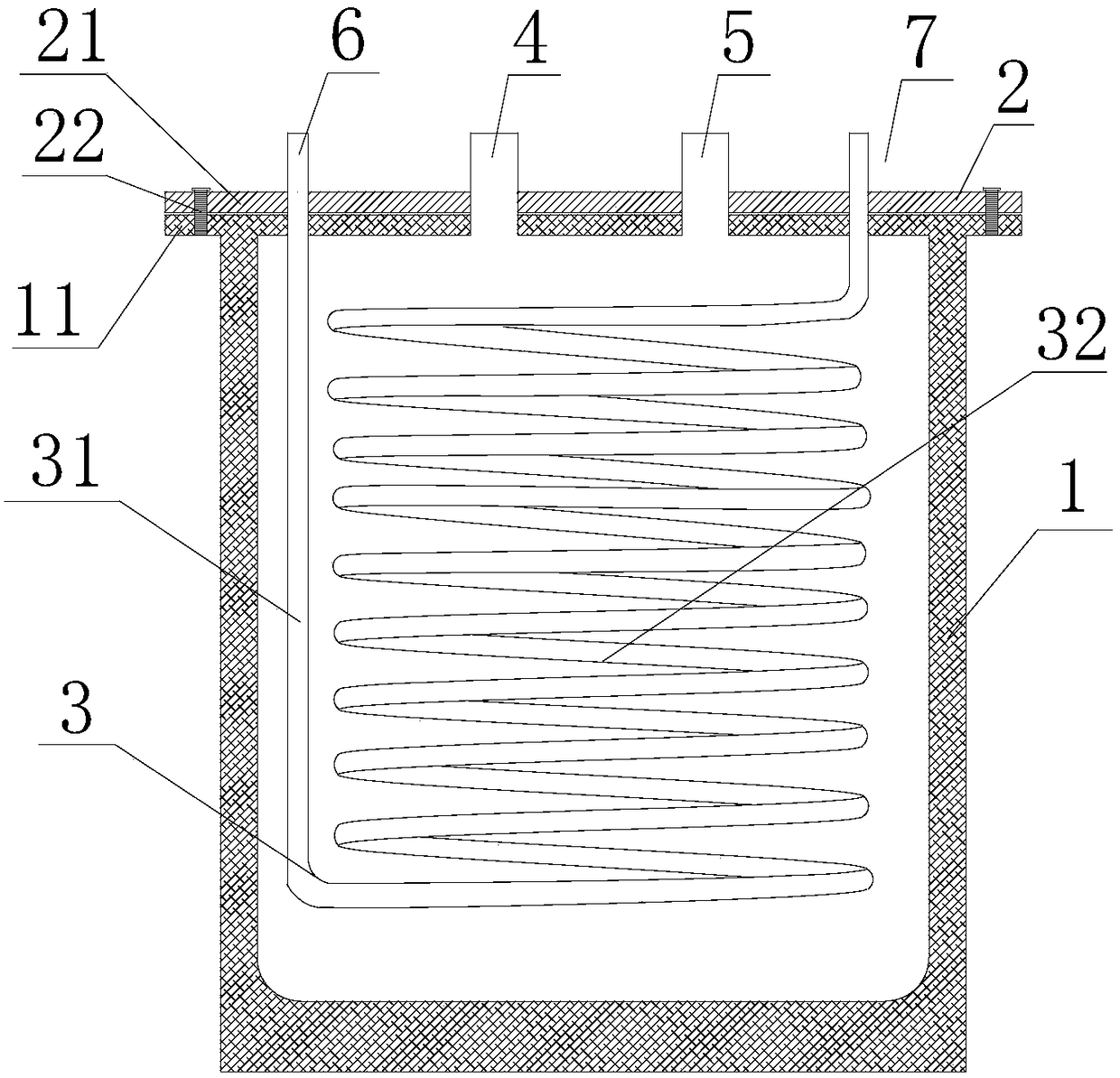

Embodiment 1

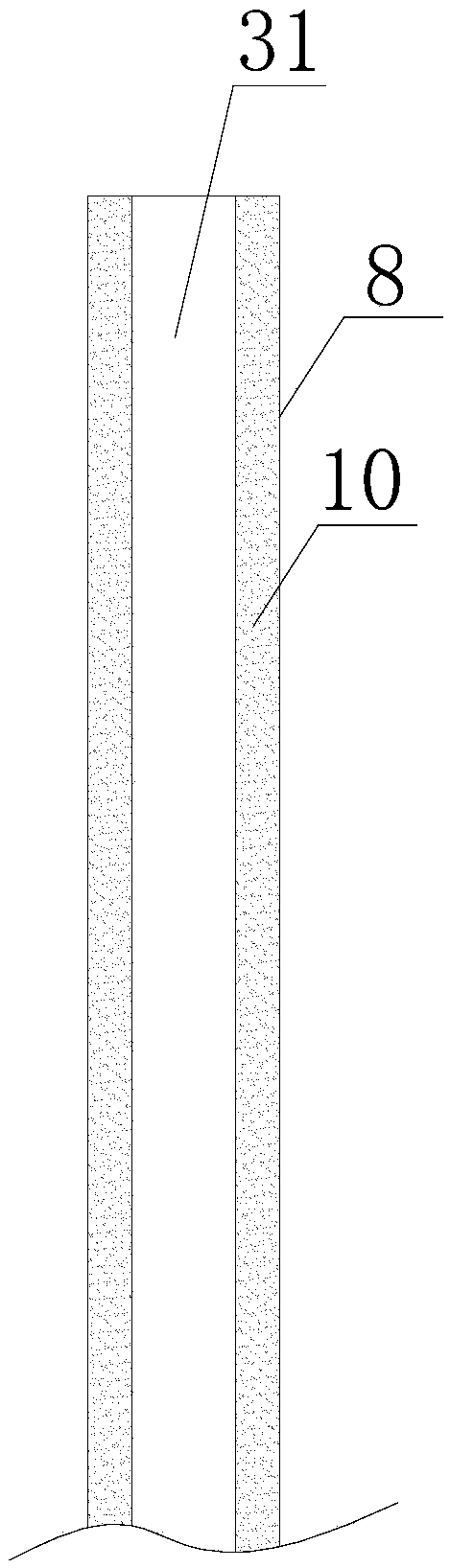

[0055] In the schemes of Examples 1 and 2, since the initial pipeline section suffers from obvious thermal shocks, the initial pipeline section will experience obvious thermal expansion and contraction. When the pipeline adopts an ordinary straight pipeline, it is very likely that The deformation caused by thermal expansion and contraction affects the stability and safety of the pipeline. Therefore, the initial pipeline section in Example 1 is improved to form Example 3.

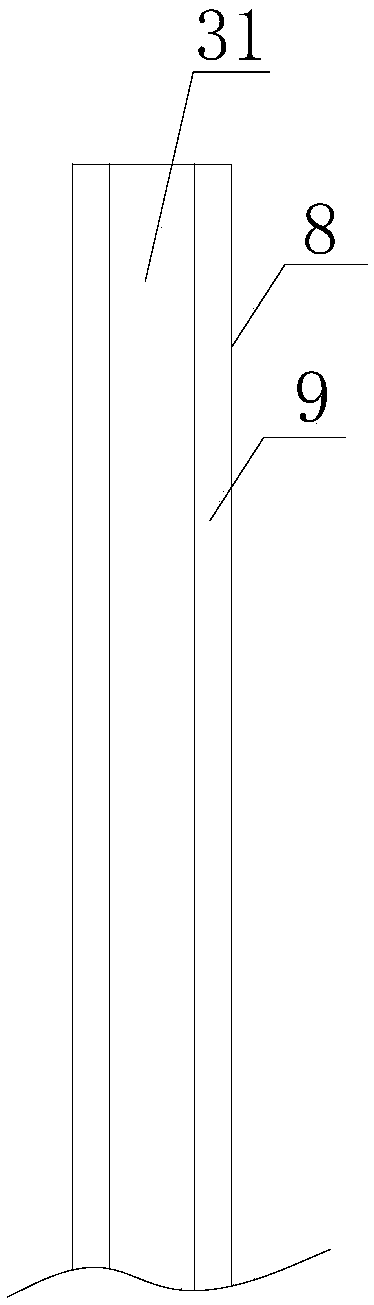

[0056] In the technical scheme of embodiment 1 and embodiment 2, such as Figure 5 As shown, the liquid inlet pipe 31 in the heat exchange pipeline 3 is transformed, the upper and lower parts of the liquid inlet pipe adopt a vertical pipeline 311, and the middle part adopts a bent pipe 312 ( Figure 5 Among them, the curved pipe line 312 includes a first horizontal pipe 3121, a vertical pipe 3122 and a second horizontal pipe 3123, the first horizontal pipe 3121 is arranged in parallel with the second horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com