Disassembling tool for disconnecting link clamping spring

A technology of clamping springs and knife switches, which is applied in the direction of switchgear, electrical components, etc., can solve problems such as tilting of the ejector rod, low disassembly success rate, and injuries caused by people falling down, so as to achieve stable force, improve stability, and avoid installation The effect of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

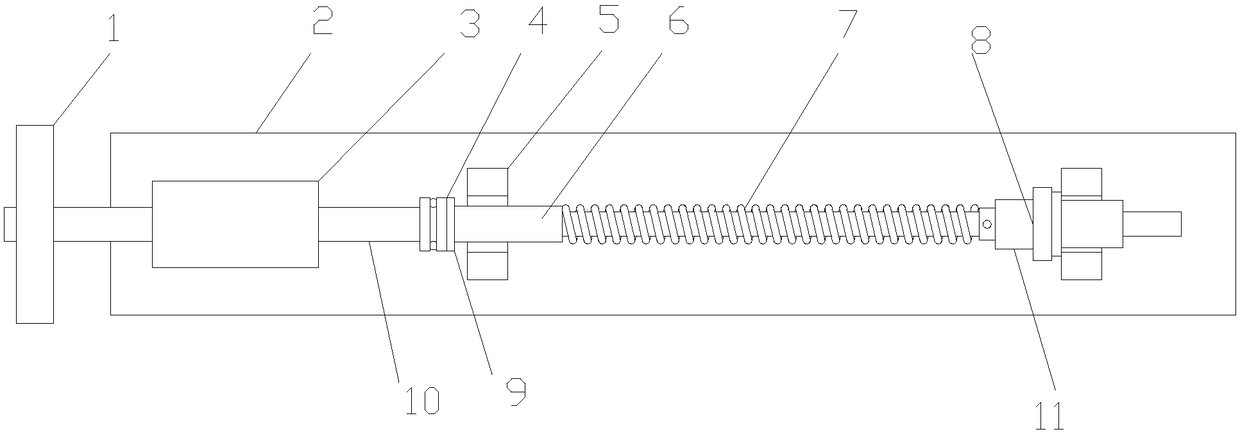

[0013] figure 1 It is a structural schematic diagram of the present invention; as shown in the figure, the knife gate clamping spring 7 disassembly tool of the present embodiment includes a horizontal support, screw mandrel 10 nuts 3 pairs, thrust bearing 4 components and linear bearing 8 components; the horizontal The bracket includes a base plate 2 and two support slots 5 fixed on the base plate 2 for supporting the knife switch; the screw 10 nut 3 pair includes a nut 3 fixed on the base plate 2 and the Cooperating screw rod 10; the thrust bearing 4 assembly is arranged at the end of the screw rod 10 for pushing one end of the knife gate ejector rod 6; the linear bearing 8 assembly is used to cover the ejector rod 6 and is used to support the spring 7 and the support slot 5; the ejector rod 6 and the spring 7 are supported by a horizontal bracket, which can improve the stability of the clamping spring 7 during disassembly. The spring 7, the screw rod 10 and the nut 3 mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com