buffer brake

A buffer braking, large-diameter technology, applied in shock absorbers, shock absorbers, steering control, etc., can solve problems such as wear and achieve the effect of suppressing sliding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

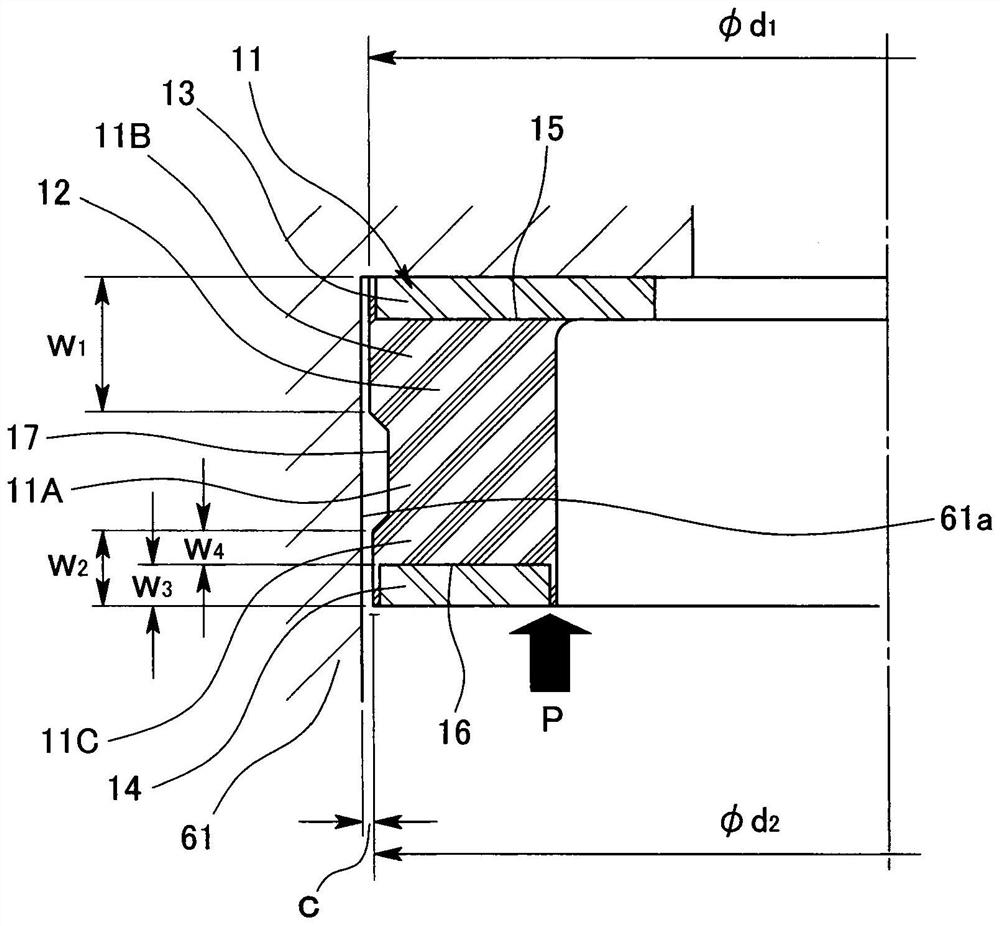

[0037] Such as figure 1 As shown, the buffer brake 11 according to this embodiment has a cylindrical elastic body 12 made of a predetermined rubber-like elastic body, and one axial end (the upper end in the figure) of the cylindrical elastic body 12 is connected to the annular The fixed side metal fitting 13 is connected to the fixed side metal fitting 13 and the other axial end portion (the lower end portion in the figure) is connected to the annular movable side metal fitting 14 . One end portion (hereinafter also referred to as the fixed side end portion 15 ) of the connection fixed side metal fitting 13 is fixed to the case 61 as a mating member. The other end portion (hereinafter also referred to as the movable side end portion 16 ) of the connecting movable side metal fitting 14 collides with a shaft (not shown) as an operation member and is displaced together with the shaft.

[0038] An annular recess 17 is provided on the outer peripheral surface of the elastic body ...

no. 2 example

[0044] It should be noted that, in the first embodiment described above, the axial width w of the movable side large-diameter portion 11C 2 is the axial width (thickness) w of the movable side metal fitting 14 3 and the axial width w between the recess 17 in the elastic body 12 and the movable side metal fitting 14 4 The sum, due to the axial width w of the movable side large-diameter portion 11C 2 becomes smaller, so this makes the axial width w between the recess 17 in the elastic body 12 and the movable side metal fitting 14 4 It is also arranged to be small, but only the axial width (thickness) w of the movable side metal fitting 14 can 3 Set the axial width w of the movable side large-diameter portion 11C 2 , in this case, the axial width w between the recess 17 in the elastic body 12 and the movable side metal fitting 14 4 is set to zero.

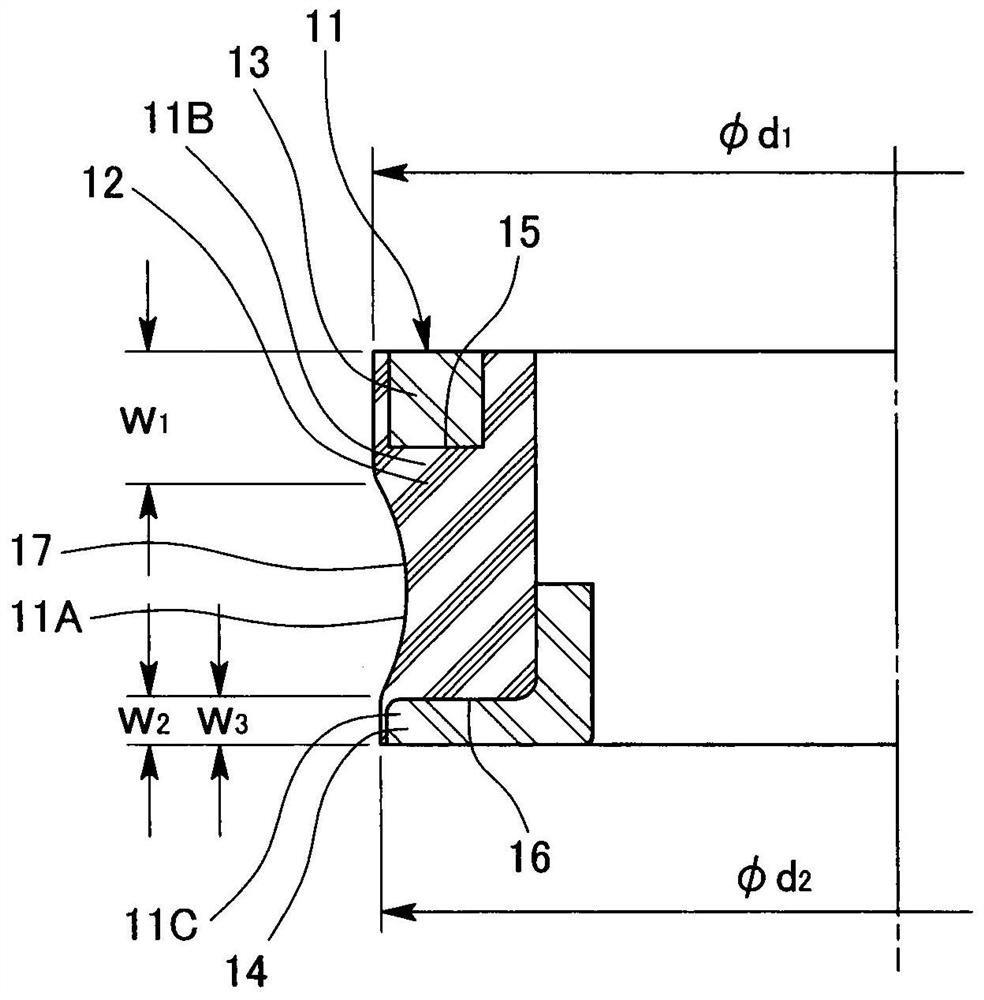

[0045] As a second embodiment, in such as figure 2 In the buffer brake 11 shown, from this point of view, only the axial widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com