Sealed chain

A chain and rigid sealing technology, applied in the transmission chain and other directions, can solve the problems of reduced sealing effect, reduced sealing function, loss of elastic sealing parts, etc., to achieve the effect of maintaining the sealing effect and suppressing sliding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

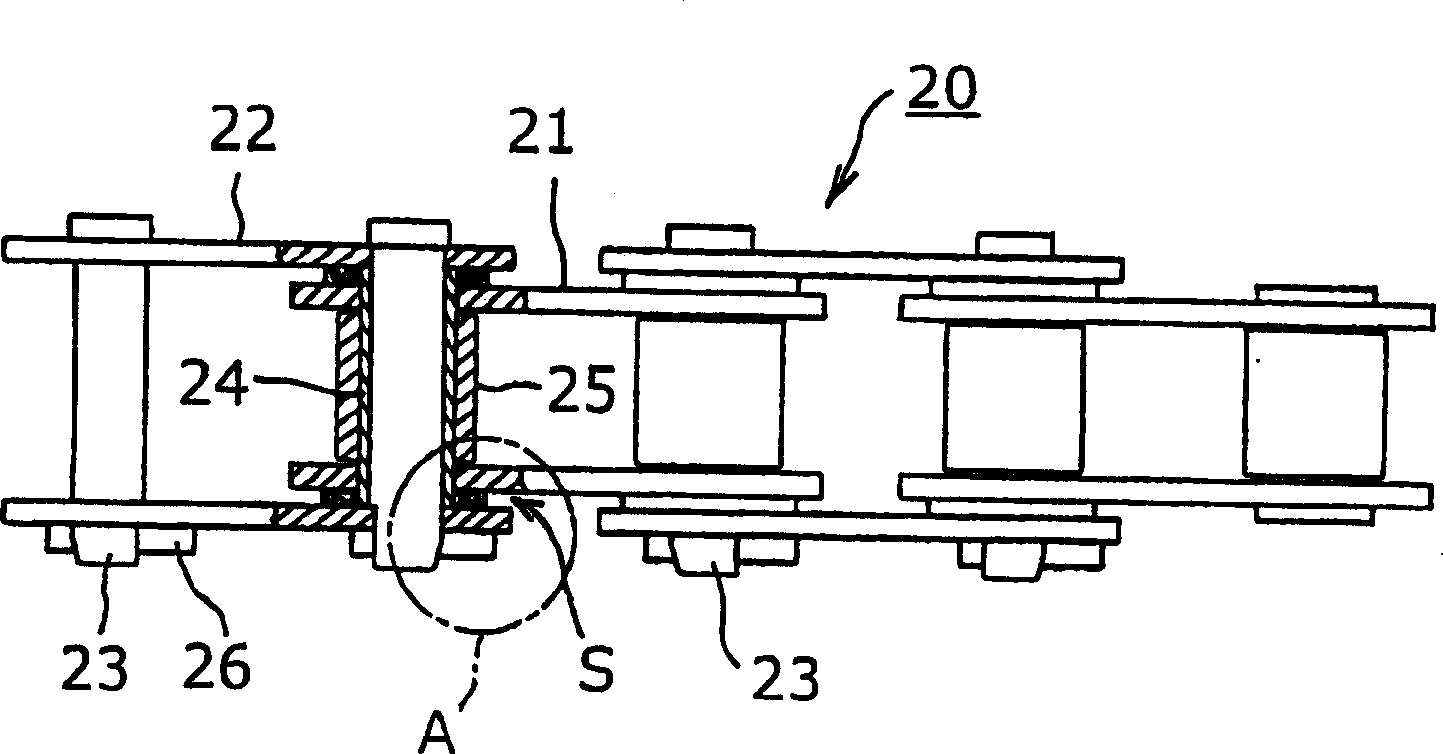

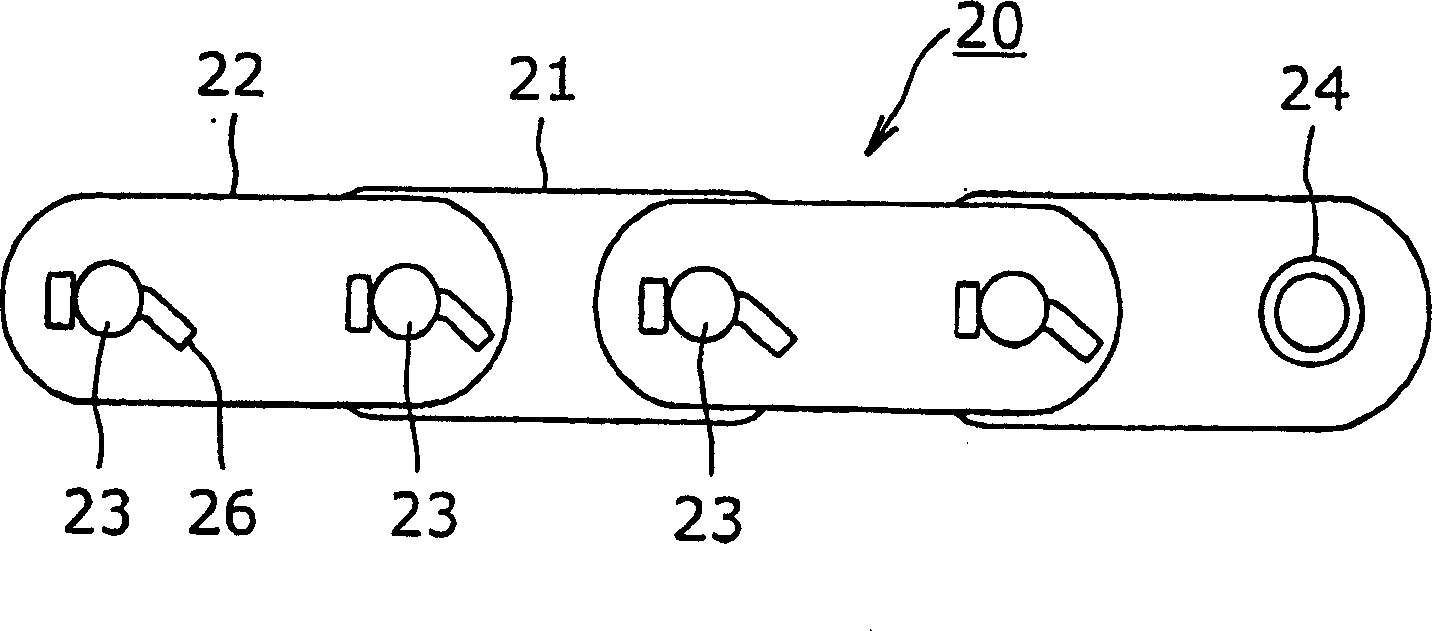

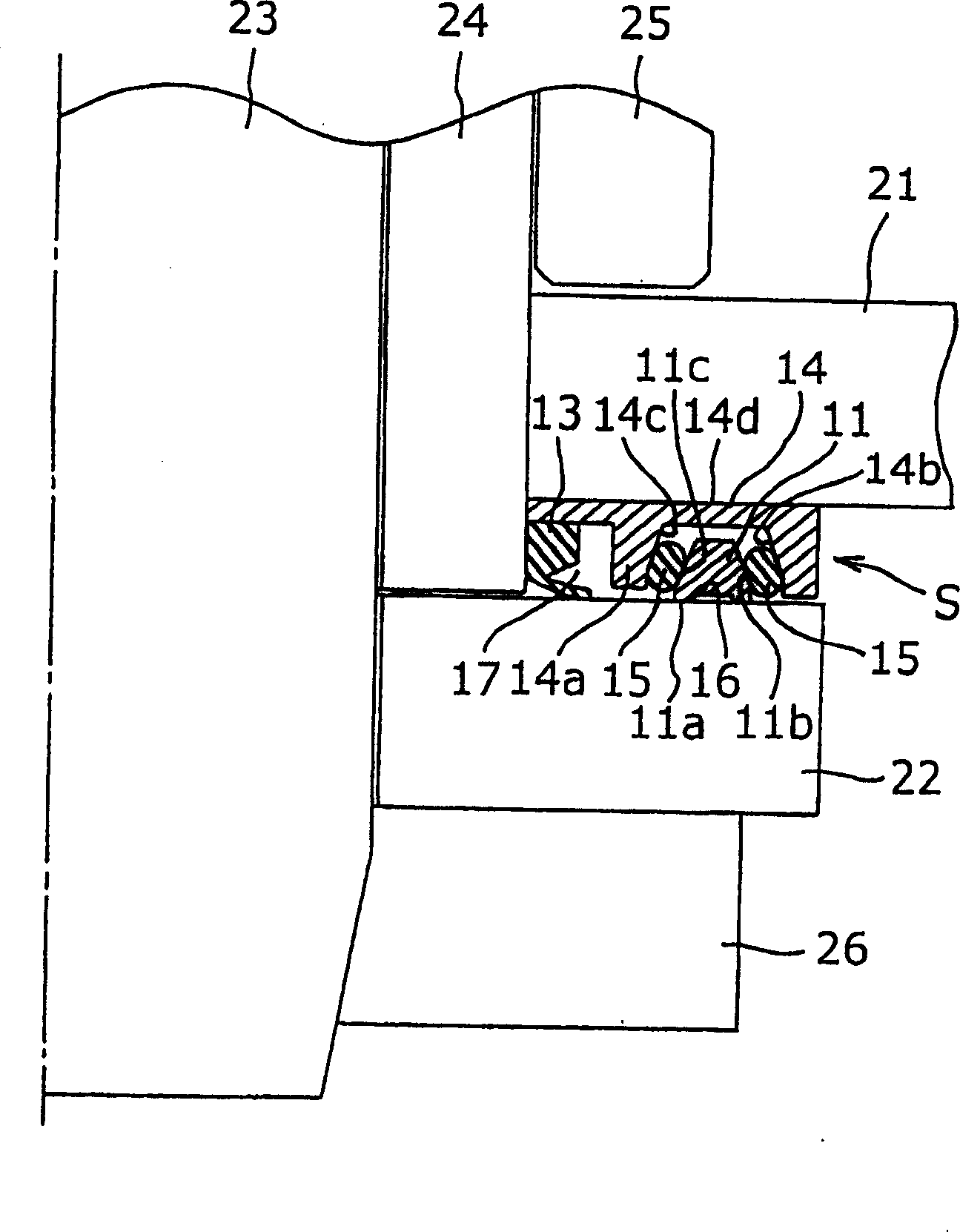

[0015] A sealing chain of an embodiment of the present invention will be described below with reference to FIGS. 1 and 2 . Specifically, Fig. 1 shows the overall structure of the sealing chain 20, figure 2 is an enlarged cross-sectional view of the seal structure that is characteristic of the seal chain of Example 1 of the present invention. figure 2 Corresponds to the portion shown by the dotted circle A in FIG. 1 .

[0016] The sealed chain 20 is a chain with a plurality of connecting components connected. In the sealed chain 20, one of the adjacent connecting components includes a pair of inner plates 21, 21 spaced apart along a direction perpendicular to the longitudinal direction of the chain, and a hollow cylindrical shape press-fitted in the pair of inner plates. Bushing 24; the other of this adjacent connection assembly comprises a pair of outer plates 22, 22 spaced apart along the direction perpendicular to the longitudinal direction of the chain at the outer side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com