Control valve for coal gas

A technology for controlling valves and gas, which is applied in the control of combustion, valve configuration, gaseous fuel supply/distribution, etc., and can solve problems such as gas explosion noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

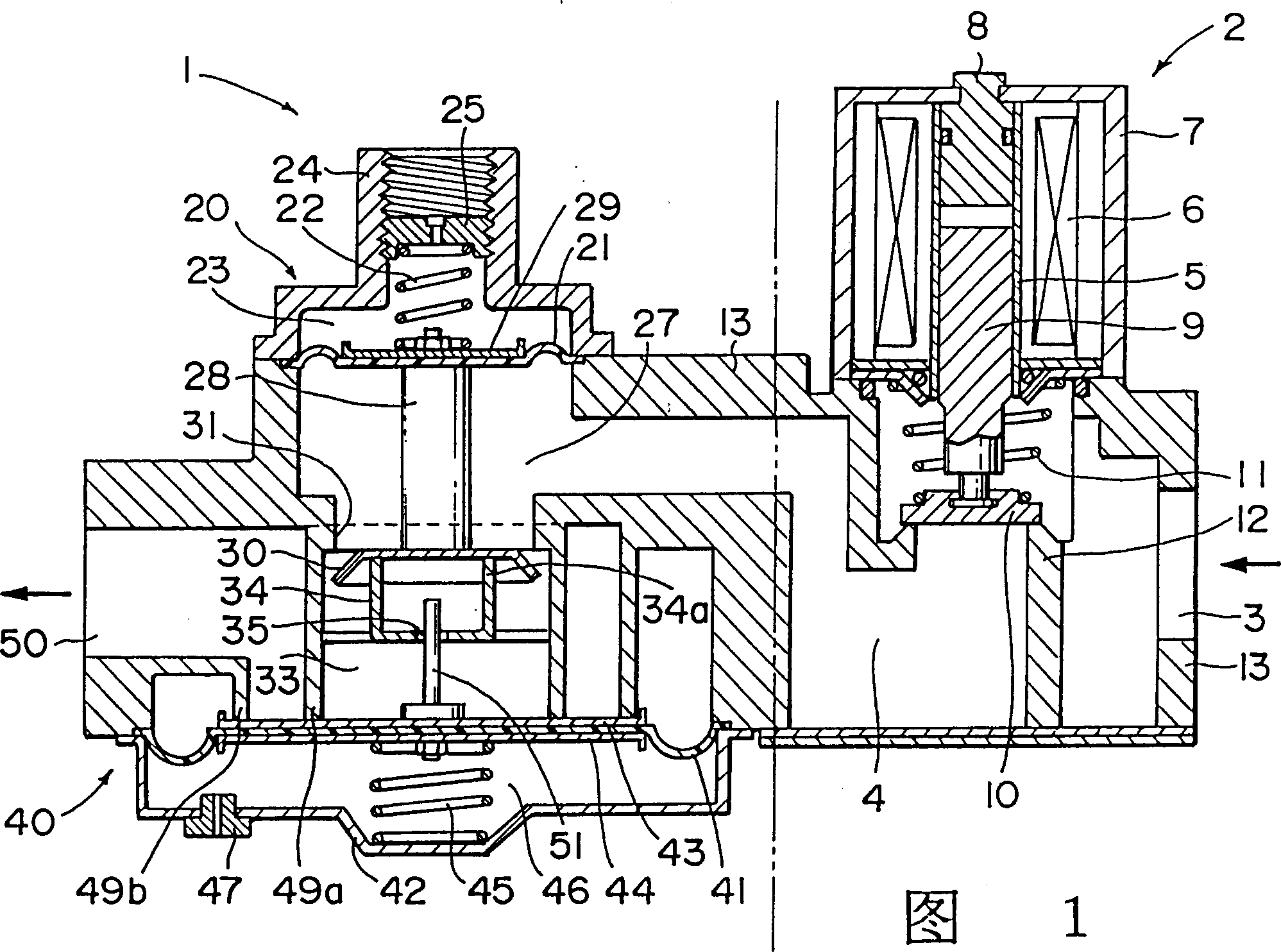

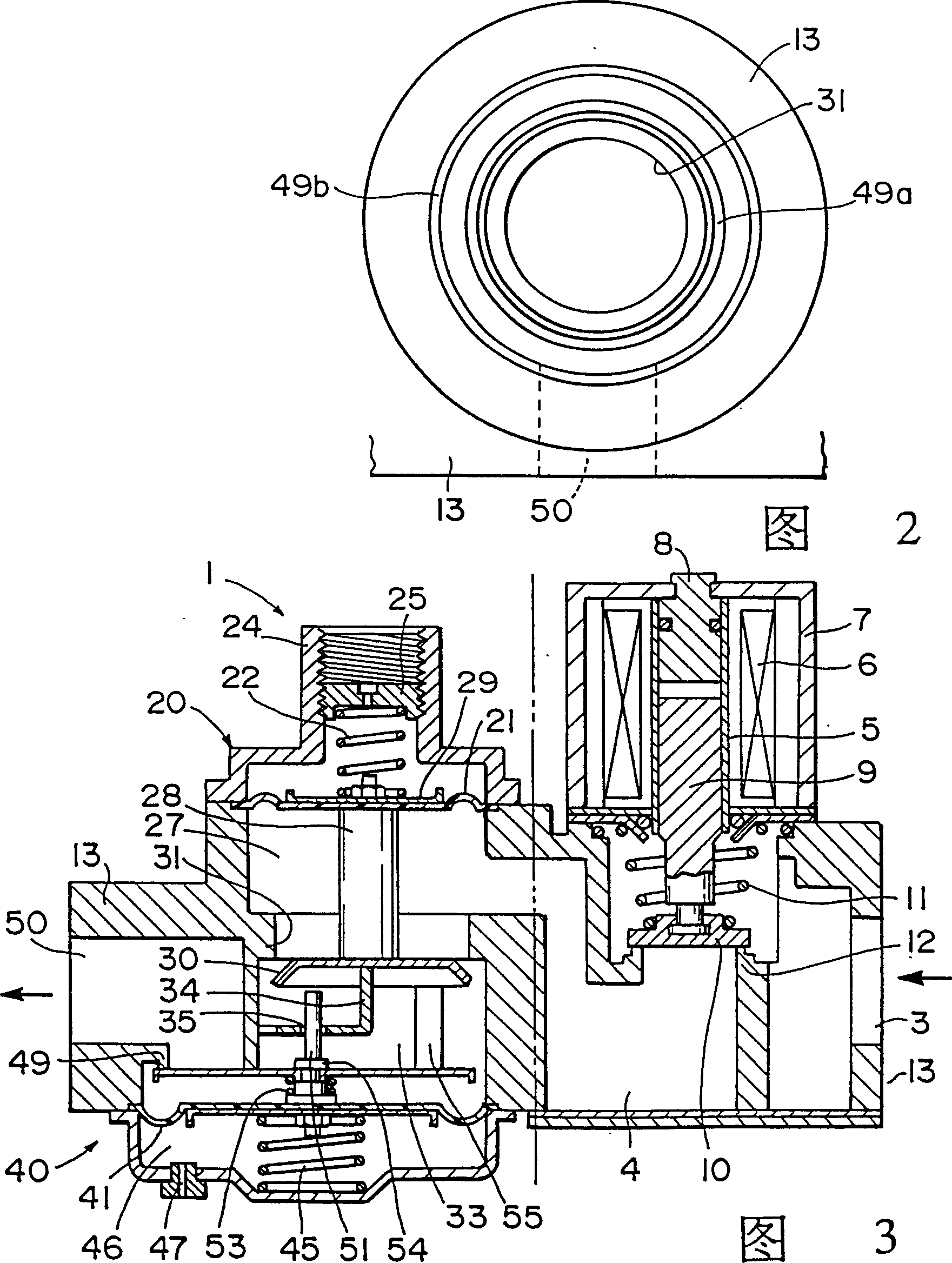

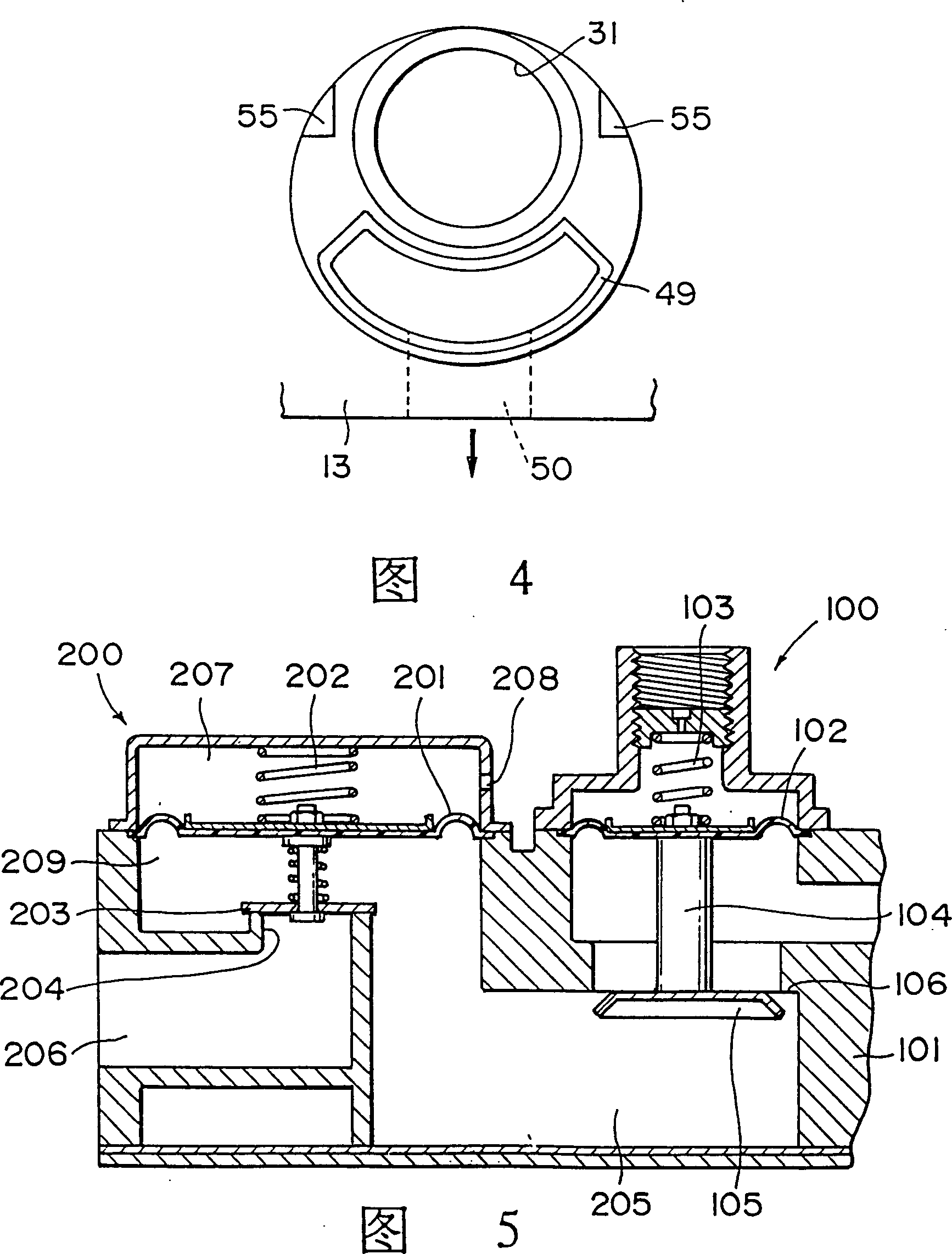

[0021] The following is an explanation of embodiments of the present invention with reference to the accompanying drawings. 1 and 2 show a first embodiment of the invention. The left area of double-dot dash line is gas control valve 1, is also connected with gas control valve 1 and has an electric electromagnetic valve 2 (in the area on the right side) that controls gas supply (on / off). The solenoid valve 2 will be explained first and then the gas control valve 1 will be explained below.

[0022] The solenoid valve 2 is arranged on the gas pipeline 4 for opening and closing the pipeline, which extends from a gas inlet 3 to the main pressure chamber 27 of the governor 20 . Electromagnetic valve 2 comprises a guide sleeve 5, an electromagnetic coil 6 around guide sleeve 5, a cover 7 covering electromagnetic coil 6, a magnetic rod 8 fixed on guide sleeve 5 top made of magnetic material such as iron, a A plunger 9 made of magnetic material such as iron, which is set in the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com