Manufacturing method of hydraulic brake device

A technology of hydraulic actuation and manufacturing methods, applied in the direction of engine components, cylinders, mechanical equipment, etc., can solve the problems of surface roughness shape management and processing without any record

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

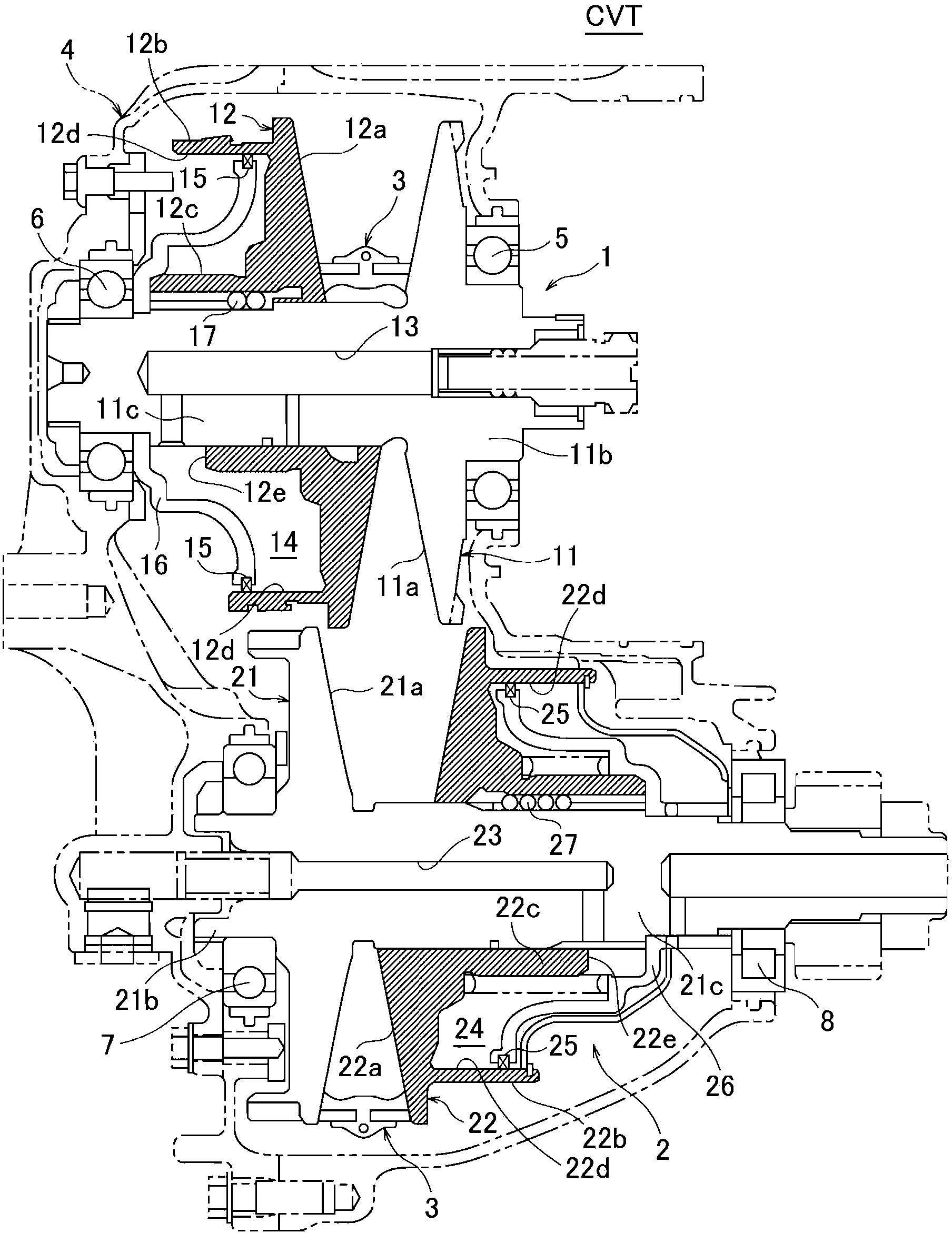

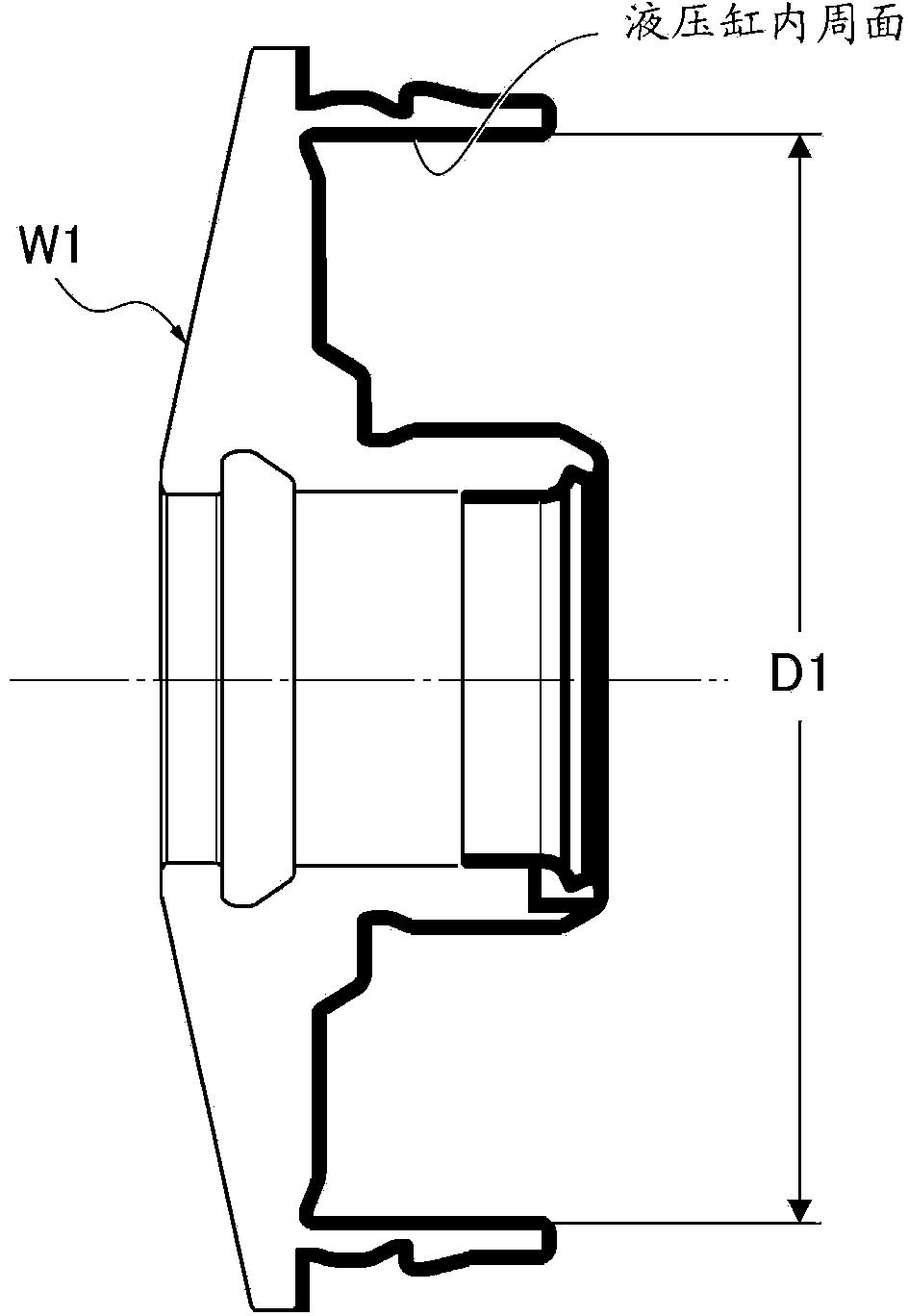

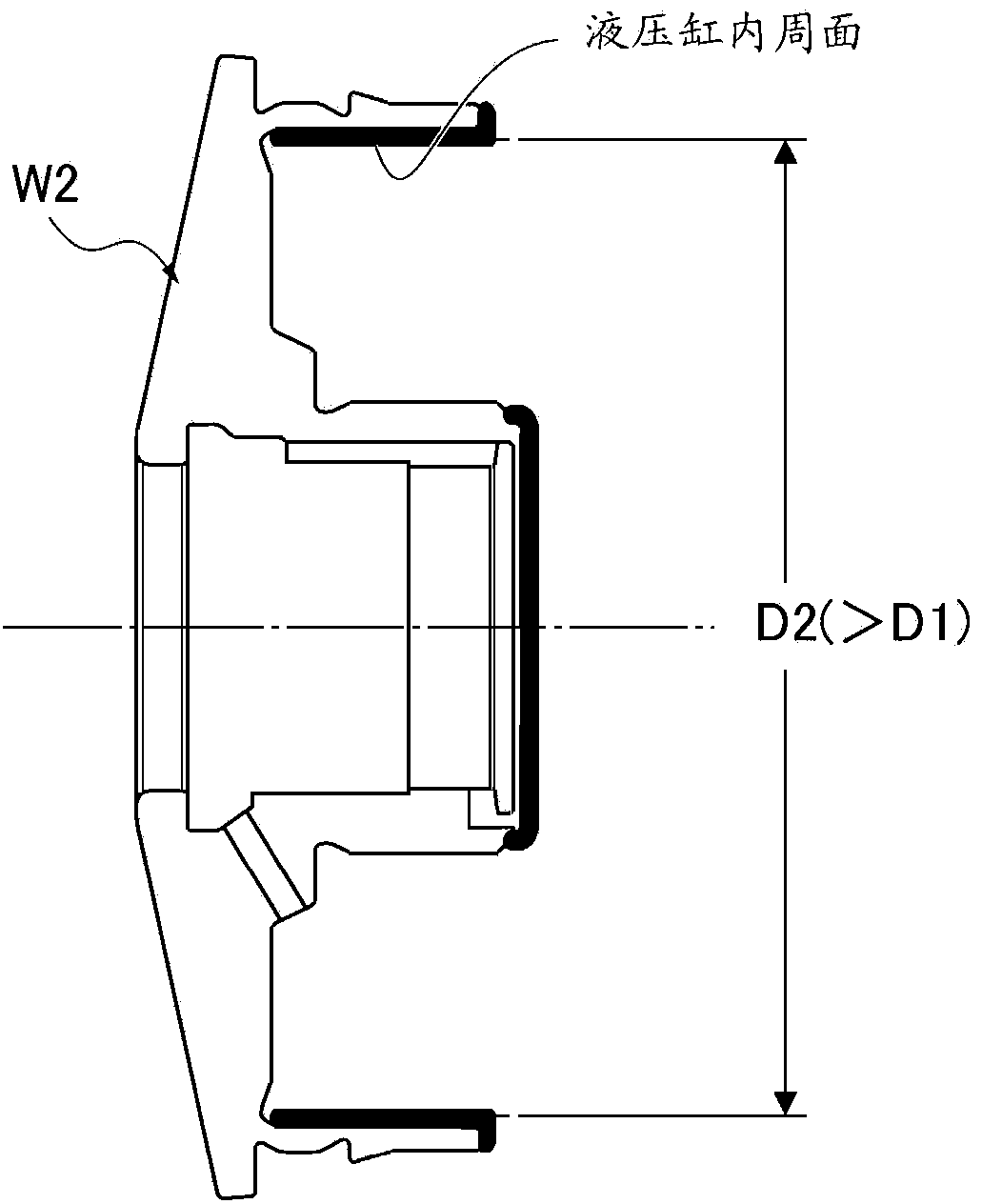

[0058] The manufacturing method of the drive pulley (an example of the hydraulic actuator) included in the belt-type continuously variable transmission of Example 1 is divided into "main part configuration of the belt-type continuously variable transmission", "manufacturing method of the drive pulley", " Outline configuration of precision cutting processing device", "Determination process of replacement of tool and tool holder", "Background technology", "Replacement determination function after finishing treatment of hydraulic cylinder inner peripheral surface", "hydraulic cylinder inner peripheral surface The role of roughness shape management" will be explained.

[0059] [Main components of a belt-type continuously variable transmission]

[0060] figure 1 A belt-type continuously variable transmission provided with a drive pulley manufactured by the manufacturing method of Example 1 is shown. Below, based on figure 1 The configuration of the main parts of the belt type co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com