Caving device and caving equipment

A technology for pits and mounting frames, which is applied in the field of pitting devices and pitting equipment, can solve the problems of large pit errors, time-consuming work, and low work efficiency, and achieve the effects of small size errors, improved work efficiency, and error avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

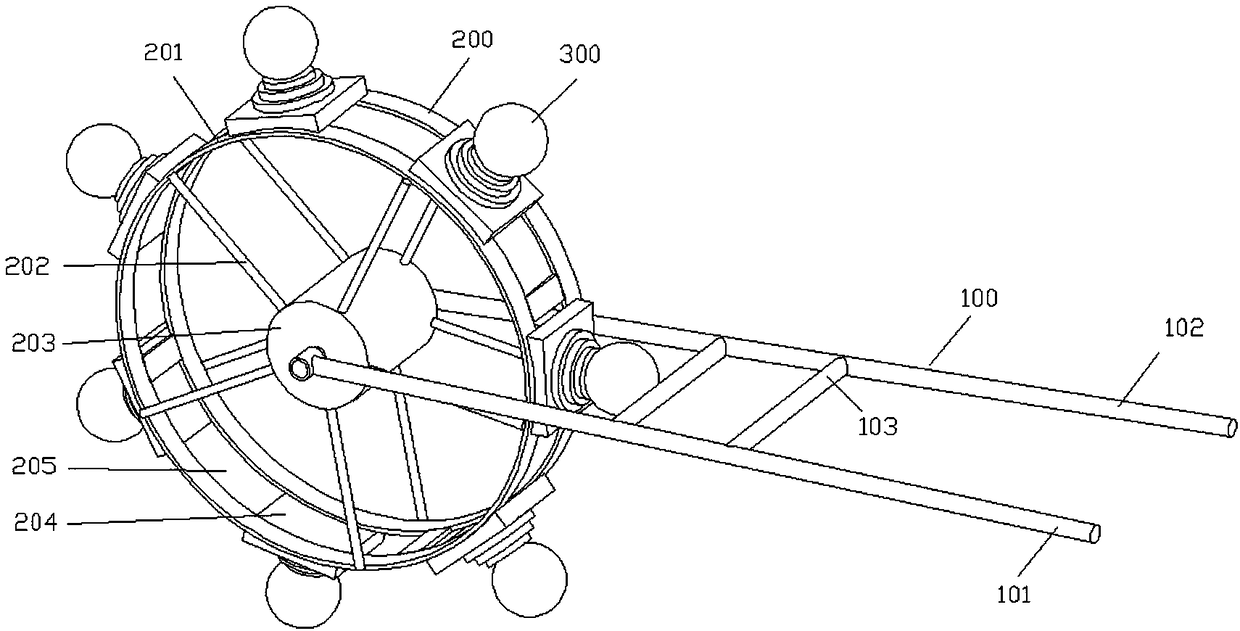

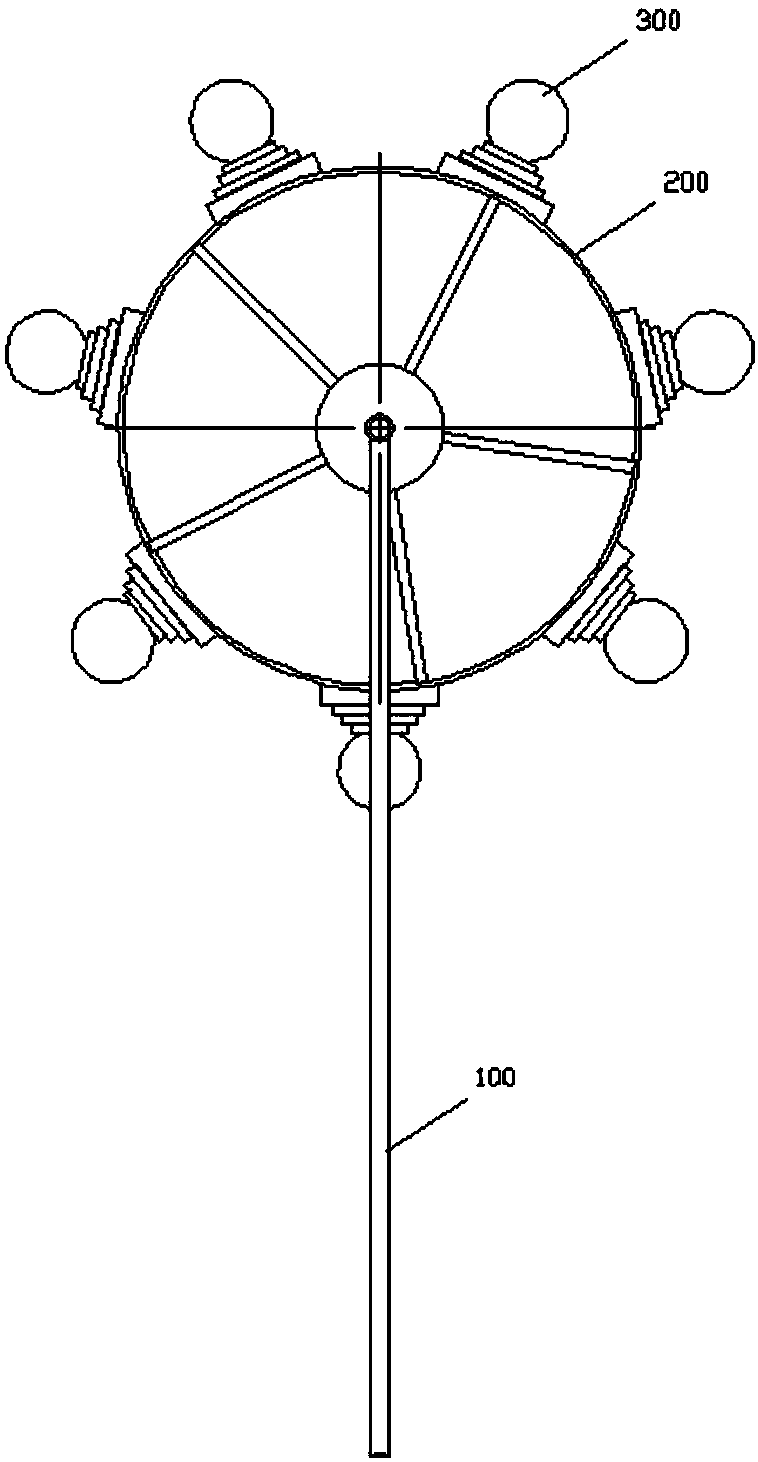

[0043] figure 1 It is a schematic structural diagram of the first cavitation device provided by the embodiment of the present invention.

[0044] Such as figure 1 As shown, a cavitation device provided by the present invention includes a push frame 100, a rotating frame 200 and a cavitation ball 300;

[0045] One end of the pushing frame 100 is used for holding by the user's hand, and the other end of the pushing frame 100 is connected with the rotating frame 200, and can push the rotating frame 200 to rotate;

[0046] The number of the cavitation balls 300 is multiple, and the cavitation balls 300 are connected to the rotating frame 200;

[0047] The pushing frame 100 pushes the rotating frame 200 to perform a rotating movement, and the rotating frame 200 can drive the hole-raising ball 300 to punch out holes on the field.

[0048] exist figure 1 Among them, the right end of the push frame 100 is used for the user's hands to hold, the left end of the push frame 100 is con...

Embodiment 2

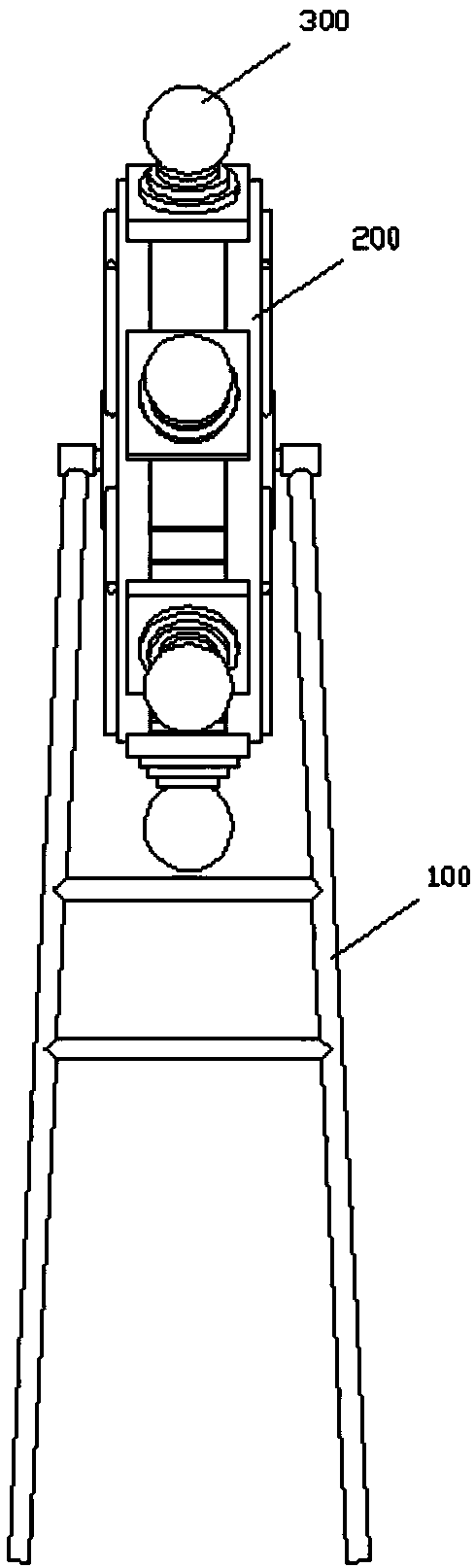

[0057] Figure 7 It is a schematic structural diagram of the second cavitation device provided by the embodiment of the present invention.

[0058] Further, the pushing frame 100 includes a first holding rod 101, a second holding rod 102 and a connecting rod 103;

[0059] One end of the first holding rod 101 is connected to one side of the rotating frame 200, and the other end of the first holding rod 101 is provided with a first holding groove 104, and the first holding groove 104 is used for It is held by one hand of the user; one end of the second holding rod 102 is connected to the other side of the rotating frame 200, and the other end of the second holding rod 102 is provided with a second holding groove 105, the second holding groove 105 is used for holding by the user's other hand;

[0060] One end of the connecting rod 103 is connected to the first gripping rod 101, and the other end of the connecting rod 103 is connected to the second gripping rod 102; the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com