Food processor with good safety

A food processor and safety technology, applied in the directions of home appliances, applications, kitchen appliances, etc., can solve the problems of no locking structure, hidden dangers, flow to the hands or the body, etc., to ensure the safety of use and improve the safety of use. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

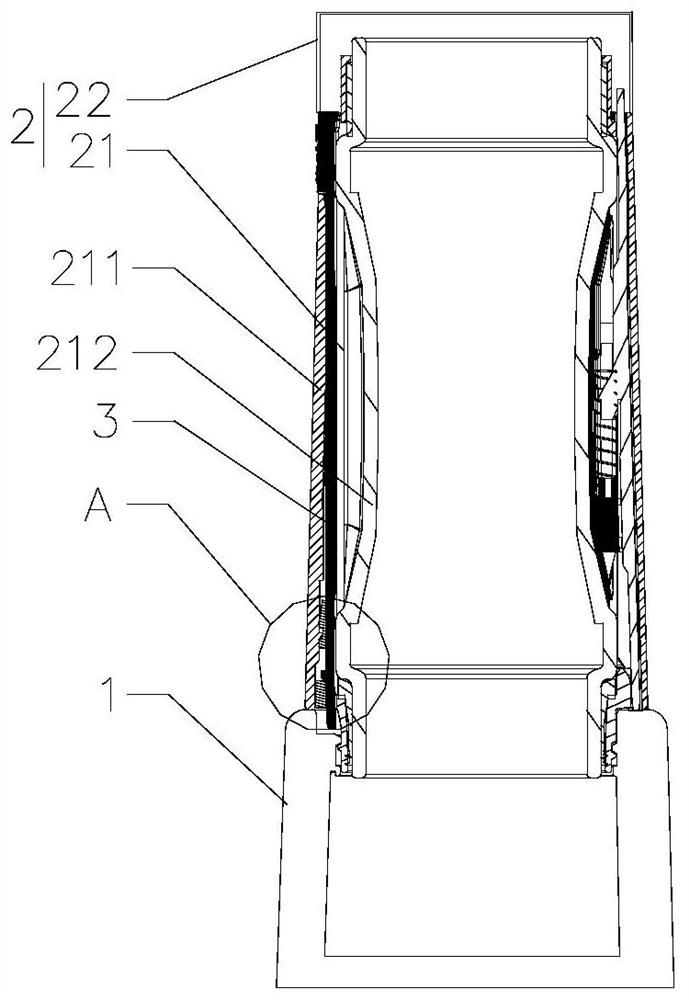

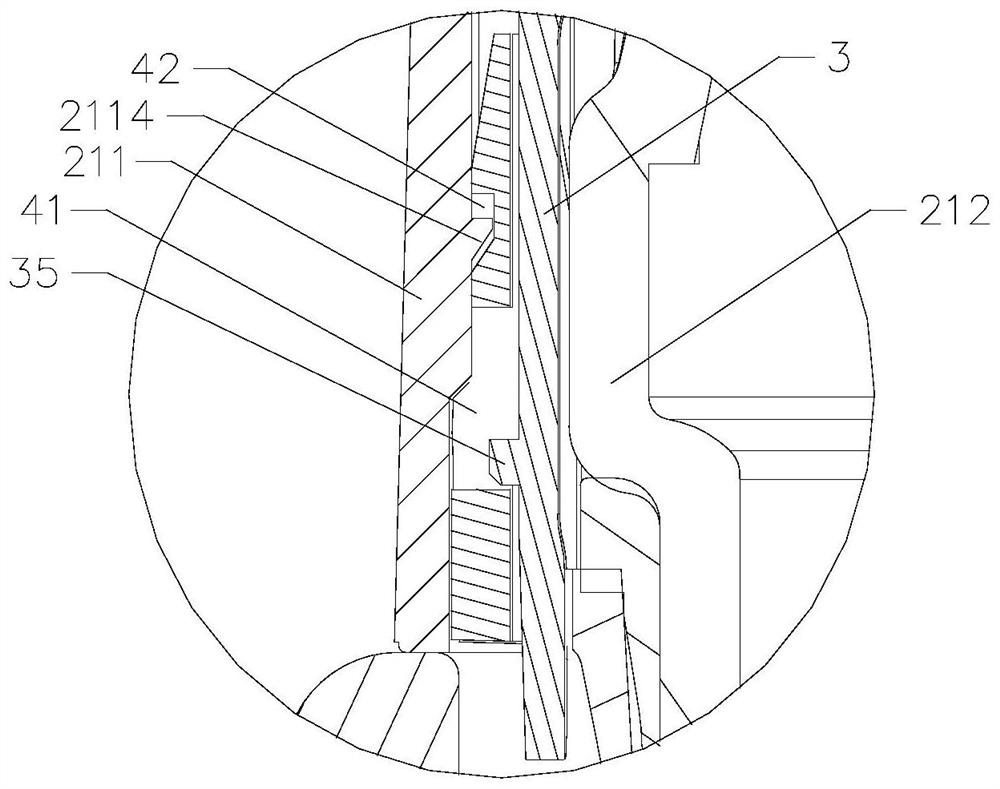

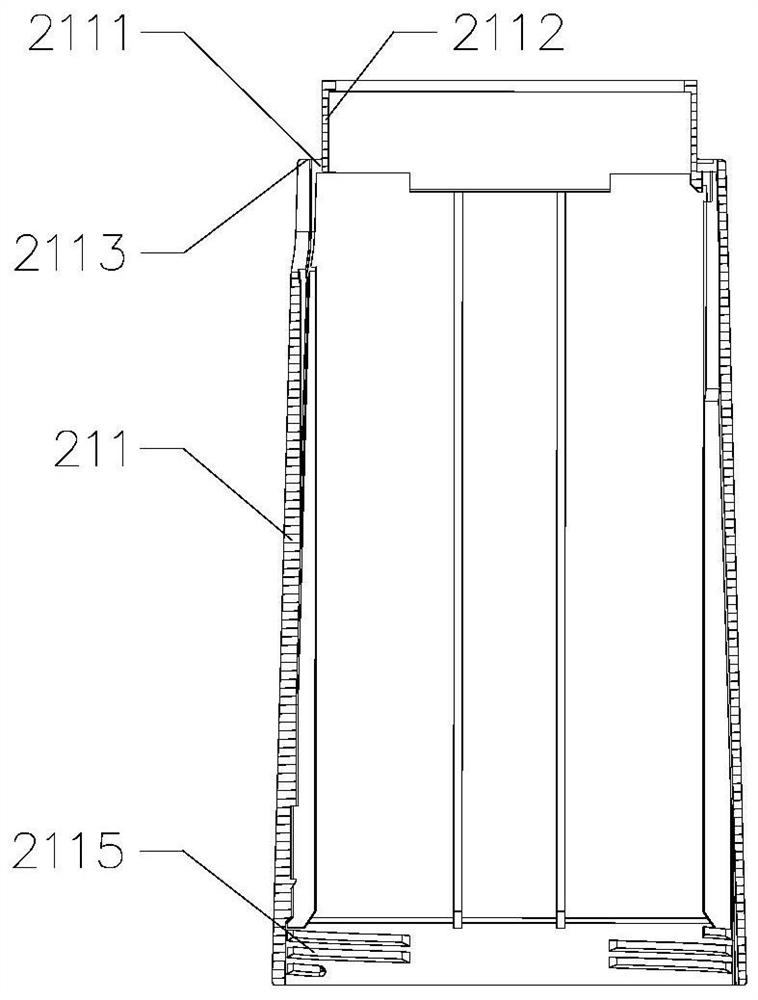

[0038] like Figures 1 to 7As shown, the present invention provides a food processor with good safety, including a machine base 1, a stirring cup 2 connected to the machine base 1, a motor installed in the machine base 1 and a pulverizer driven by the motor, and the stirring cup 2 It includes a cup body 21 and a cup cover 22, wherein the cup body 21 includes an upper opening and a lower opening, that is, the cup body 21 is provided with upper and lower openings, specifically, the cup cover 22 is arranged on the upper opening, and the lower opening is detachably connected with the machine base 1 , the motor includes a motor shaft, the crushing knife is fixed on the upper end of the motor shaft, and after the cup body 21 is connected to the machine base in place, the crushing knife extends into the cup body 21 from the lower opening, and the cup cover 22 is closed on the upper opening , so as to form a crushing chamber to crush and stir the materials and slurry.

[0039] In thi...

Embodiment 2

[0052] The difference between this embodiment and the first embodiment lies in that the locking structure is different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com