Novel highly-efficient and energy-saving electric heat supply food dryer

A high-efficiency energy-saving, food drying technology, applied in food drying, food preservation, food processing and other directions, can solve the problems of easily damaged food surface, hard texture of the turning mechanism, and easy to contaminate food, etc., to improve the safety of turning and drying. Good effect, good turning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

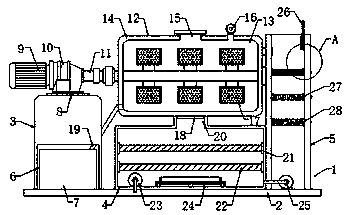

[0022] Such as Figure 1-4As shown, a new type of high-efficiency and energy-saving electric heating food dryer includes a dryer body 1, a bearing plate 2 is arranged at the bottom of the dryer body 1, a base 3 is installed on the top surface of the bearing plate 2, a heating box 4 and reflow box 5, a motor frame 8 is fixedly installed on the top of the base 3, a rotating motor 9 is detachably connected to the motor frame 8, and a speed reducer 10 is connected to the output end of the rotating motor 9. The heating box 4 is located between the base 3 and the reflow box 5, the top surface of the heating box 4 is provided with an air outlet 20, and the inner walls of both sides of the heating box 4 are fixedly installed with heating pipe mounting seats 21, A heating pipe 22 is detachably connected between the heating pipe mounting bases 21, a blower 24 is installed in the middle part of the bottom of the heating box 4, and an air pump 23 is installed on one side of the blower 24,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com