Sealing structure and dust collector comprising same

A technology of sealing structure and vacuum cleaner, which is applied in the direction of vacuum cleaners, suction filters, cleaning equipment, etc., can solve the problem of micro switch contact damage and other problems, and achieve a good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

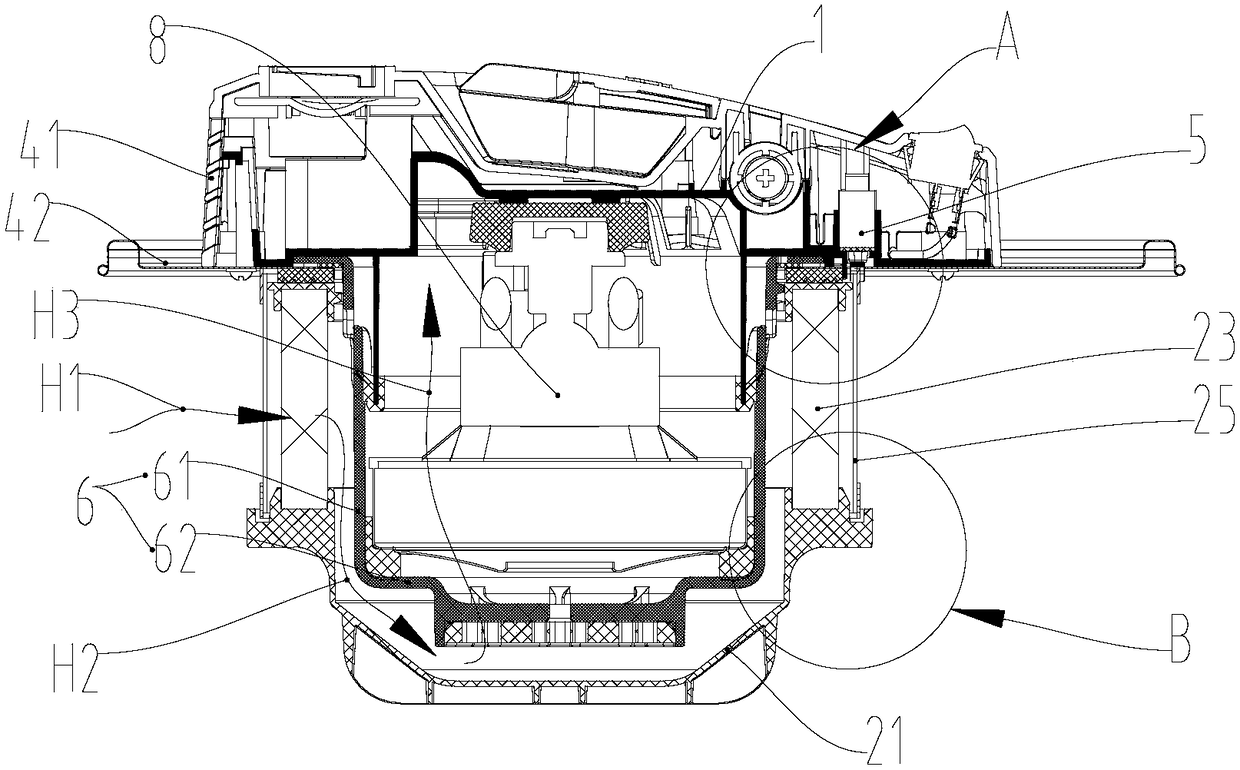

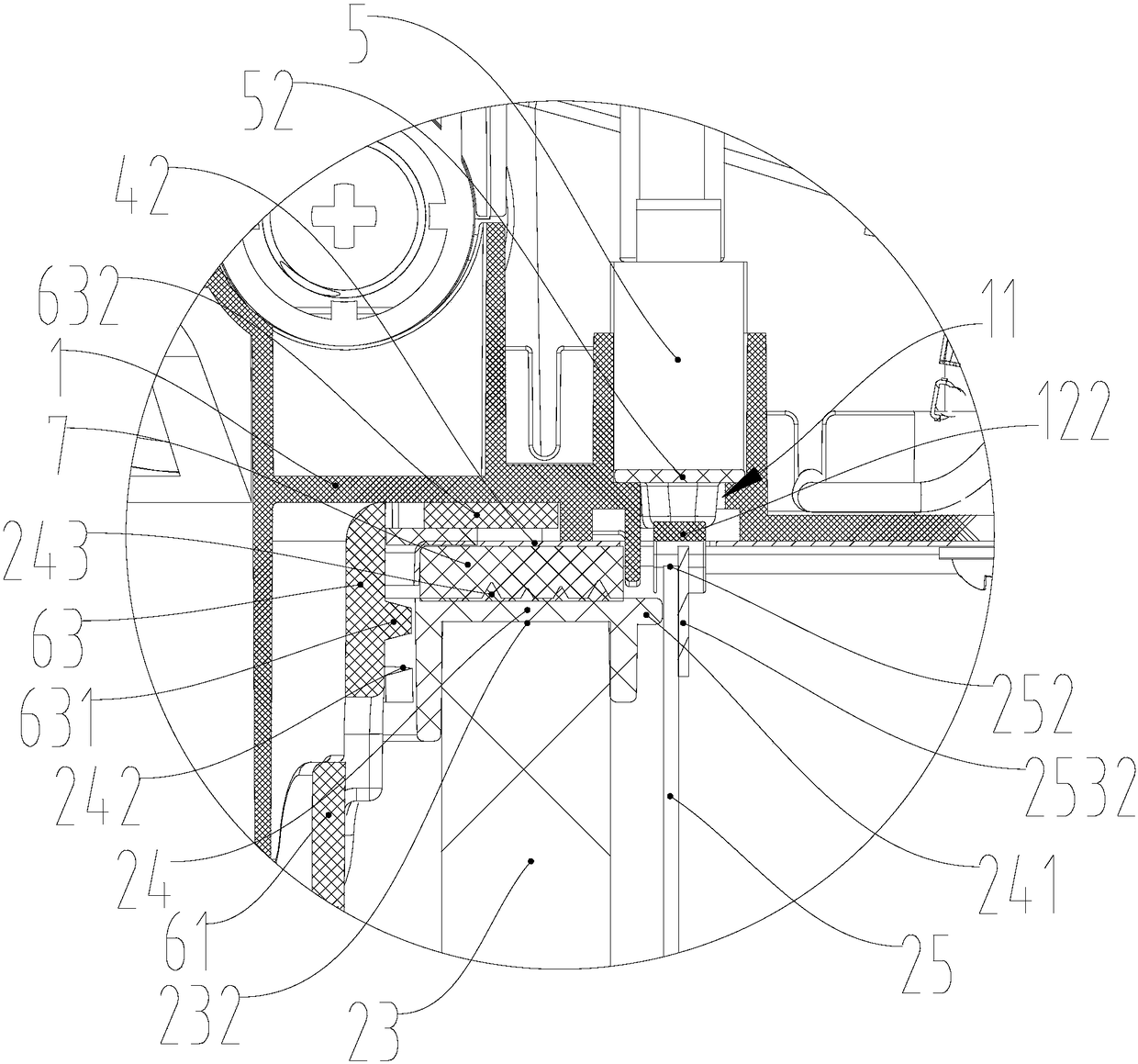

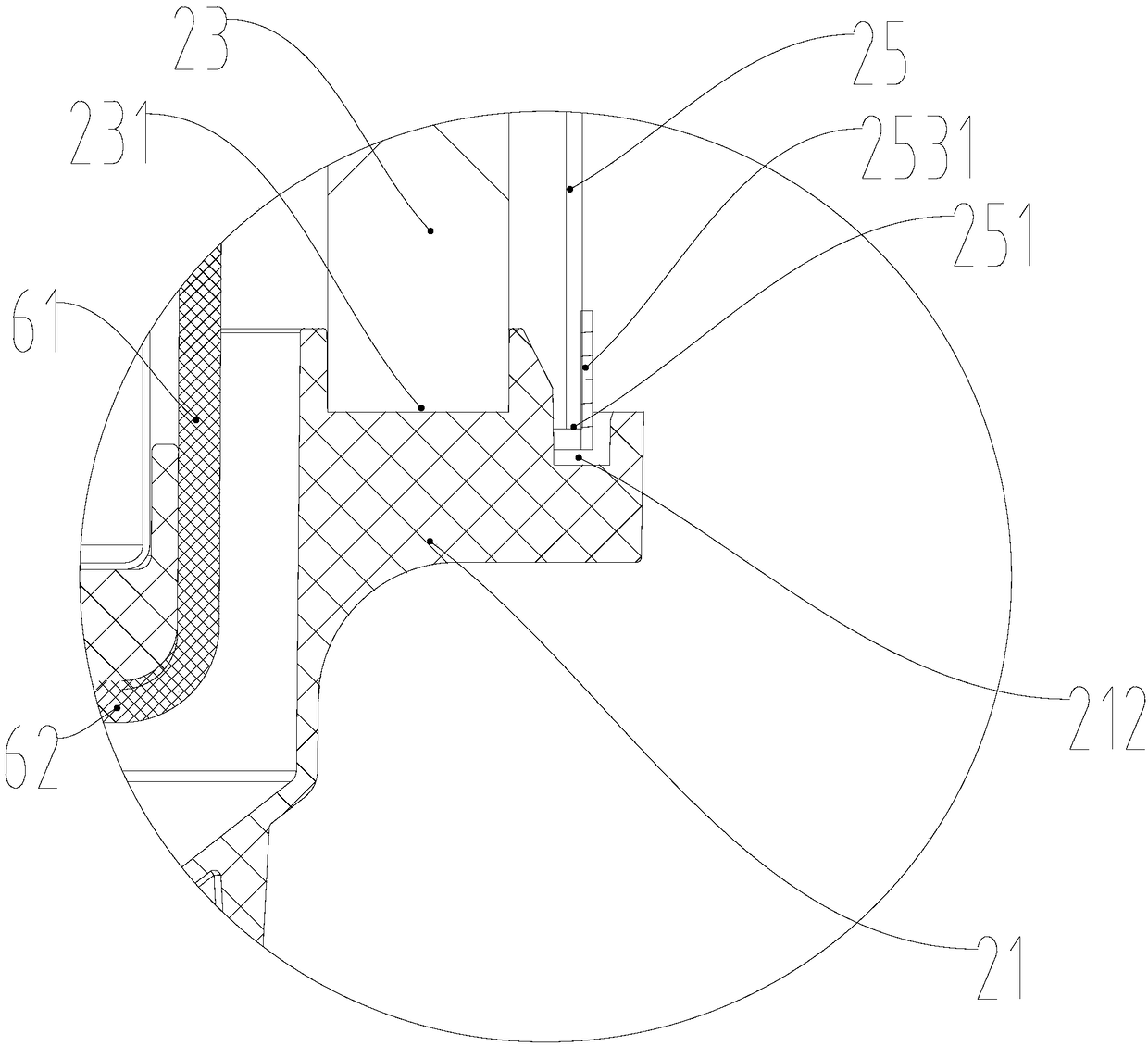

[0038] In this embodiment, as shown in FIGS. 2 to 9 , an elastic arm 121 is provided in the through hole 11 . One end of the elastic arm 121 is provided with an indenter 1211, the thickness of the indenter 1211 is obviously greater than the thickness of the elastic arm 121, specifically, the indenter 1211 protrudes downward, and in other embodiments, the indenter 1211 protrudes upward; The other end of 121 is connected to the inner wall of the through hole 11. Specifically, the elastic arm 121 is integrally formed with the windshield 1. Since the elastic arm 121 itself is made of elastic material, the pressure head 1211 can move up and down along the axial direction of the through hole 11. Specifically, when pressure is applied, the pressure head 1211 moves along the pressure direction; when the pressure is released, the pressure head 1211 resets under the action of the elastic arm 121 . In some other embodiments, the elastic arm 121 is elastically pivoted to the inner wall of...

no. 2 approach

[0051]In this embodiment, as shown in FIG. 10 , the windshield 1 further includes a linkage part 9, and the linkage part 9 includes an abutment 91 arranged on the upstream side of the windshield 1 and a trigger 92 hinged to the middle of the abutment 91. The trigger 92 moves in the through hole 11 along its axial direction. Specifically, both the abutting piece 91 and the triggering piece 92 are rod-shaped. The first end 911 of the abutting member 91 corresponds to the installation position of the first filter 23 , and the second end 912 of the abutting member 91 corresponds to the installation position of the second filter 25 . The first end 921 of the trigger member 92 is pivotally connected to the middle part of the abutment member 91 through the pivot 93 , and slide grooves 923 are symmetrically arranged on both sides of the middle part of the trigger member. A symmetrical third protrusion 111 extends toward the center of the through hole 11 from the position correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com