Continuous hot-galvanizing unit with pre-galvanizing leveling function and hot-galvanizing process

A tempering machine and leveling technology, applied in the direction of hot-dip galvanizing process, metal material coating process, coating, etc., can solve the problems of restricting the use of hot-rolled galvanized products and failing to meet the higher quality requirements of galvanized products. Achieve the effects of reducing equipment investment and personnel costs, increasing the total yield, and meeting the requirements of precision use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] For ease of description, this embodiment takes hot-dip galvanizing as an example for subsequent descriptions. When producing other types of hot-dip products by changing the composition of the plating solution, you can refer to the treatment process in this embodiment.

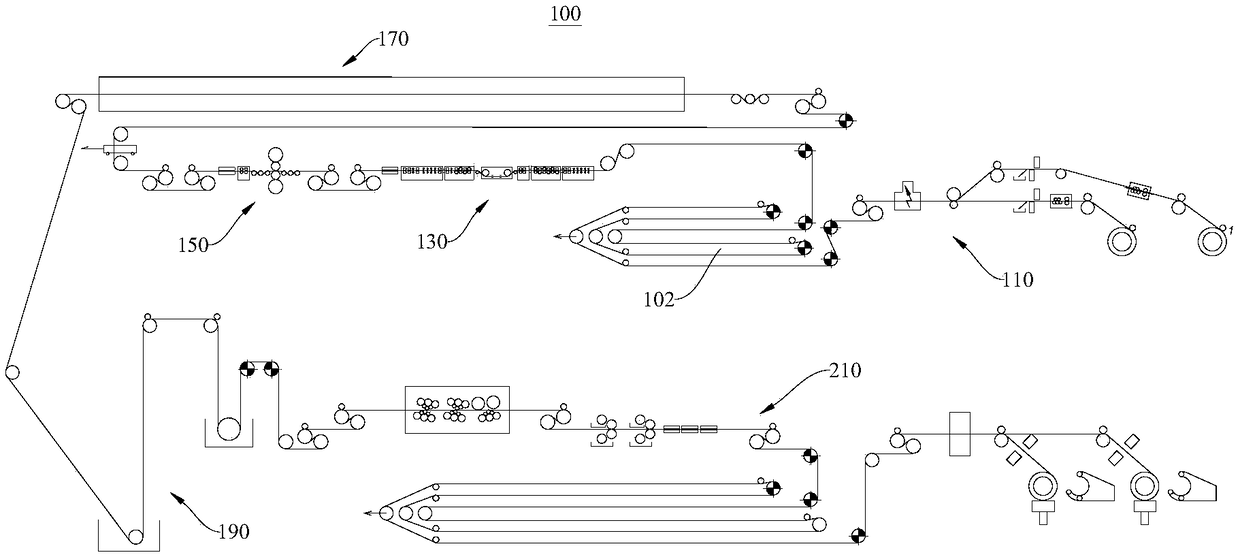

[0043] Please refer to figure 1 , figure 1 Shown is a schematic structural diagram of a continuous hot-coating unit 100 with a pre-plating leveling function. This embodiment provides a continuous hot-dip galvanizing unit 100 with the function of leveling before plating, which is mainly used for galvanizing with hot-rolled steel sheets as raw materials, and improves the quality of galvanized sheets made of hot-rolled steel sheets compared with traditional units, so that The galvanized sheet can meet the requirements of more users and broaden the use of the galvanized sheet.

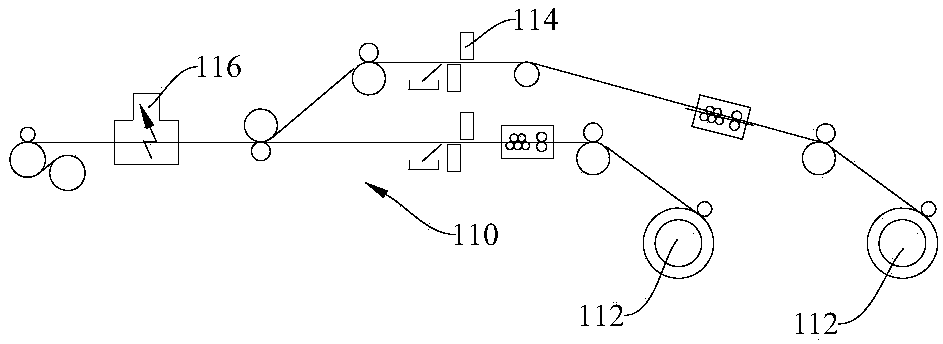

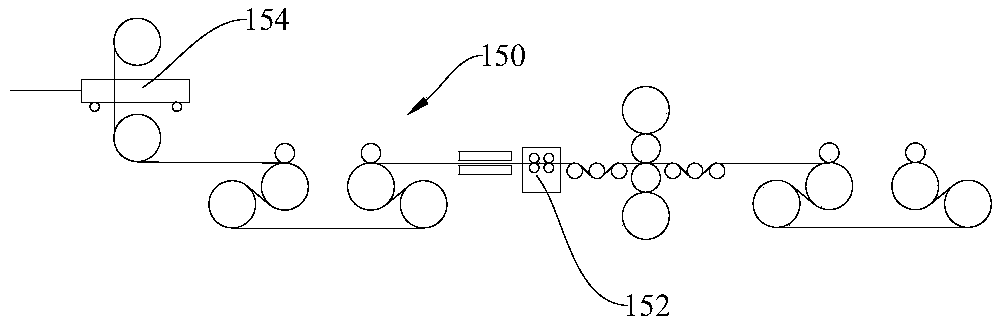

[0044] The continuous hot-dip plating unit 100 with pre-plating leveling function includes a pretreatment section 110 , a cleanin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com