Steel coil pickling leveling unit and steel coil production method

A technology of tempering machine and steel coil acid, applied in the field of steel processing, can solve the problems of insufficient perfection and unsatisfactory finished steel coils.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

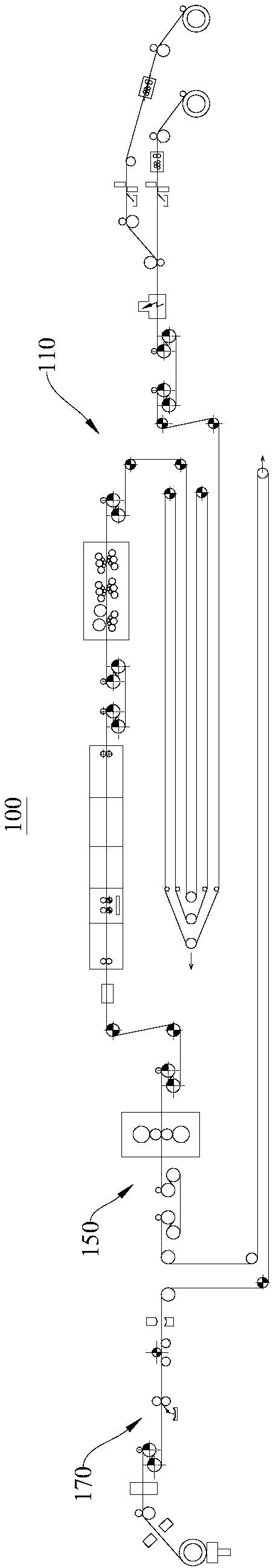

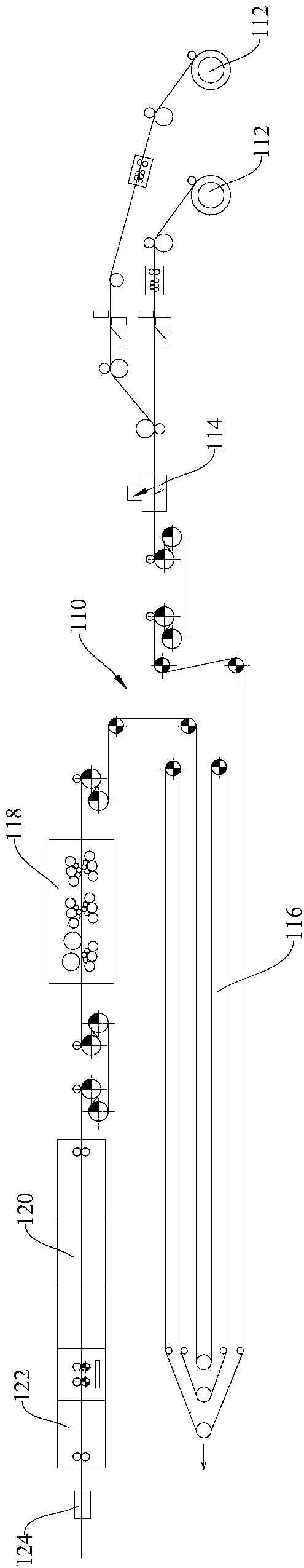

[0031] Please refer to figure 1 , figure 1 Shown is the schematic diagram of the steel coil pickling and leveling unit 100. The steel coil pickling and leveling unit 100 can be mainly used for pretreatment of raw material steel coils, and the pretreated steel coils can be used as raw materials for subsequent cold rolling and galvanizing or can also be used directly. In this embodiment, the treatment of the steel coil and the galvanizing of the steel coil are used as an example for subsequent description. Of course, in other embodiments, the steel plate can also be processed, and the surface of the steel plate can also be plated with other materials, such as aluminum.

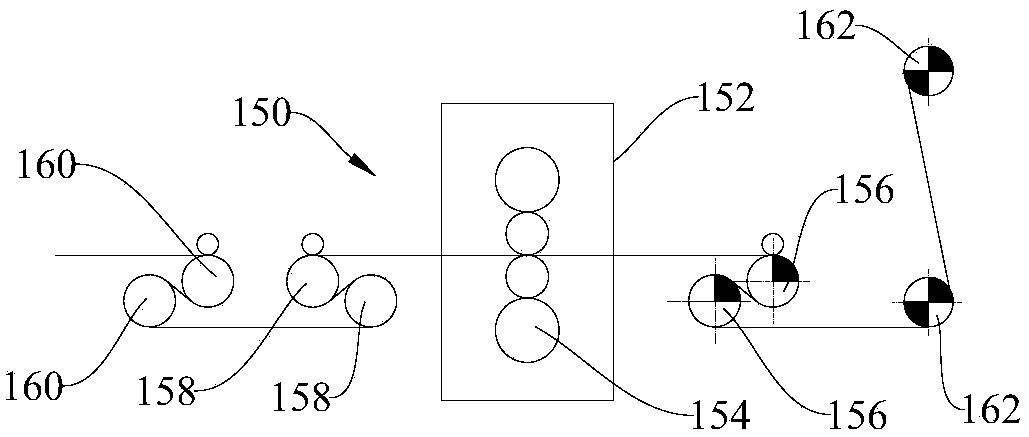

[0032] This embodiment provides a steel coil pickling and leveling unit 100, which includes a cleaning section 110, a leveling section 150, and a post-processing section 170 connected in sequence. The cleaning section 110 is mainly used to clean the raw steel material to remove surface debris such as iron oxide sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com