A prestressed tension tooling

A prestress and tension technology, applied in the direction of strengthening molding, can solve problems such as low production efficiency, and achieve the effect of shortening production time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention are described below so that those skilled in the art can understand the present invention, but it should be clear that the present invention is not limited to the scope of the specific embodiments. For those of ordinary skill in the art, as long as various changes Within the spirit and scope of the present invention defined and determined by the appended claims, these changes are obvious, and all inventions and creations using the concept of the present invention are included in the protection list.

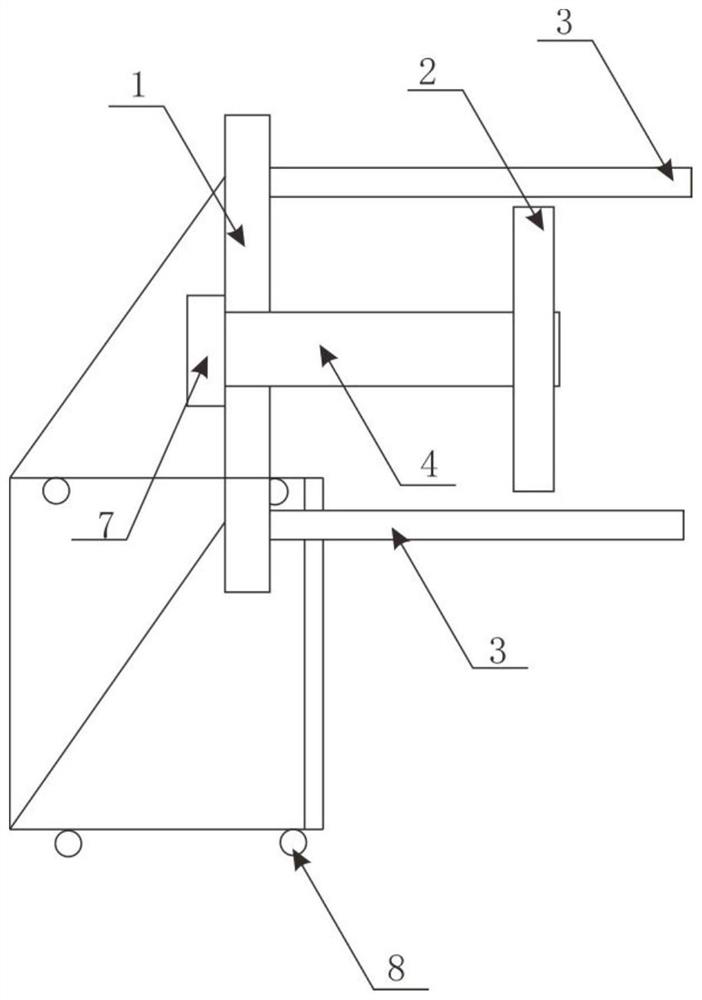

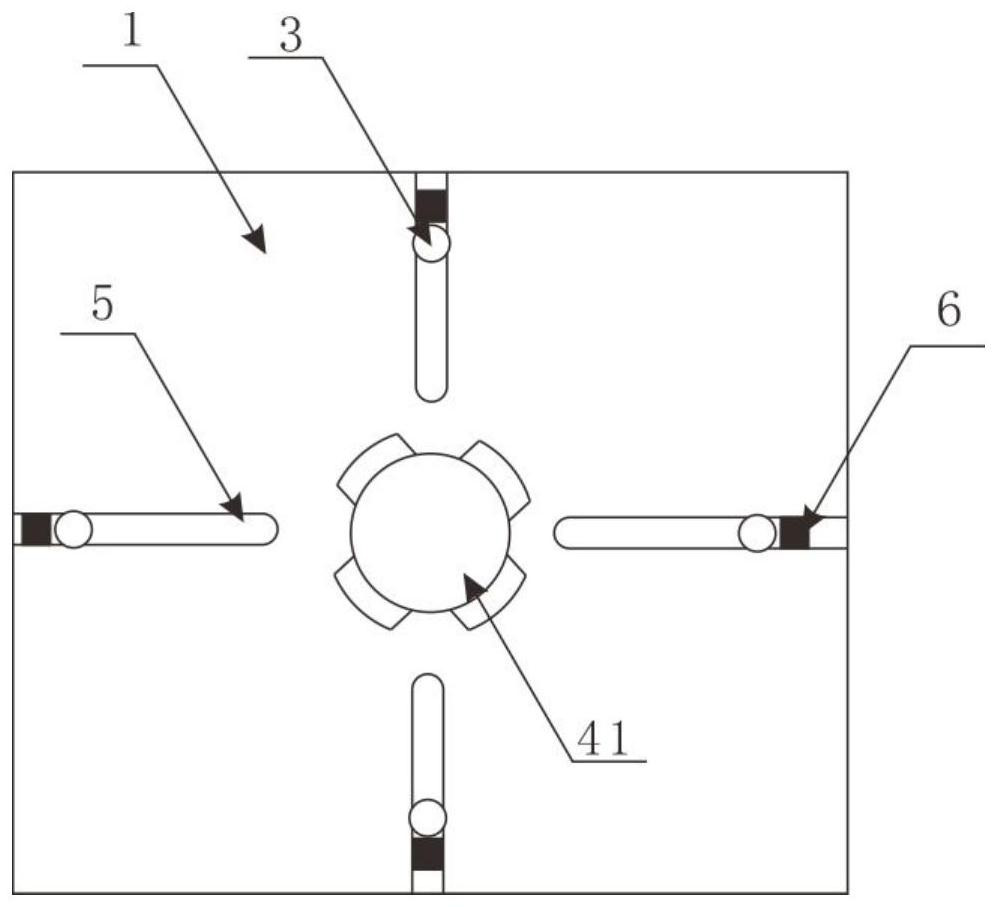

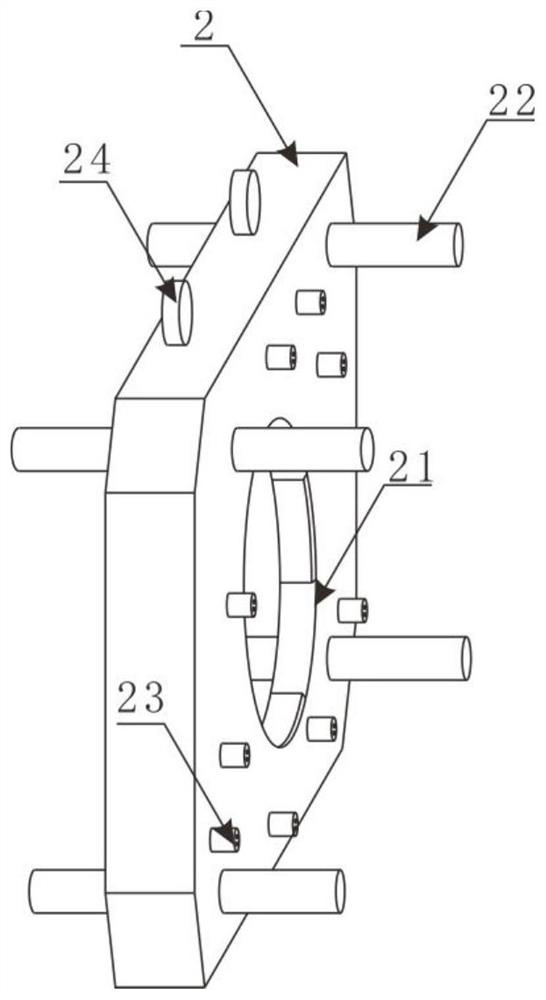

[0027] Such as figure 1 As shown, the prestressed tension tooling includes a stool foot plate 1 used in conjunction with each other and a tension plate 2 with a suspension ring 24 on the top, and a bracket for supporting the stool foot plate 1 is provided under the stool foot plate 1, and in The bottom of the support is provided with several rollers 8, preferably the number of rollers 8 is 4, which is convenient for carryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com