Hollow brick clamping device

A clamping device and hollow brick technology, applied in construction, building structure, construction material processing and other directions, can solve problems such as easy to hurt hands, low efficiency, etc., achieve the effect of simple structure, convenient operation, and improve the efficiency of moving bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

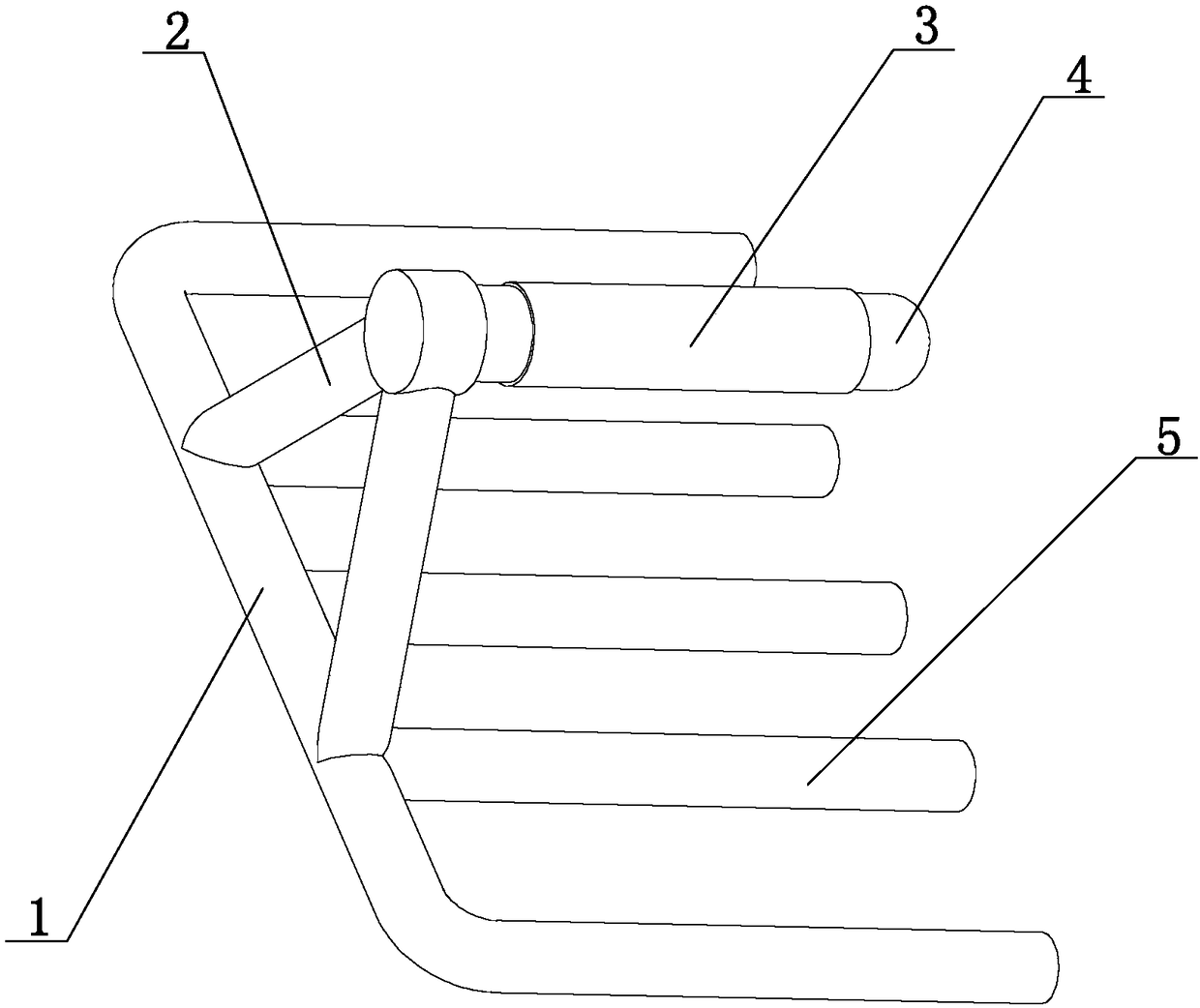

[0013] Such as figure 1 As shown, the present invention includes a connecting rod 1, an inserting rod 5, a support frame and a handle 4. Five inserting rods 5 are fixedly welded on the connecting rod 1, and each inserting rod 5 is correspondingly inserted into one of the hollow holes on a hollow brick. , all the insertion rods 5 are arranged horizontally with a certain distance from each other, the support frame is composed of two support rods 2 arranged obliquely, the support frame is in the shape of a cone, and the large end of the support frame is fixedly connected with the connecting rod 1, The small end of the bracing frame is fixedly connected with the handle 4, the center line of the bracing frame is perpendicular to the center line of the connecting rod 1, the handle 4 is suspended laterally above the insertion rod 5, and the handle 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com