An adaptive and high-precision method for extracting rolling stock profile based on continuous rolling simulation

An adaptive, high-precision technology, applied in the field of steel rolling, can solve problems such as misalignment and inaccurate pass profile extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] The embodiment of the present invention is based on the continuous rolling simulation self-adaptive, high-precision method for extracting the profile of a rolled piece, comprising the following steps:

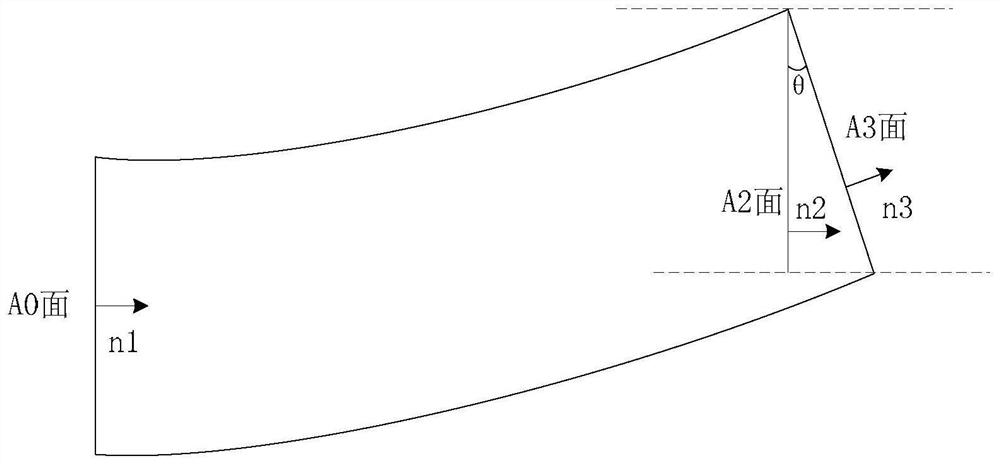

[0042] Take the middle section of the pre-rolled piece as the extraction section after rolling, and track the rolling progress of the section to determine the extraction range of the section, and then perform bending contour correction and / or torsion on the steel contour corresponding to the extraction position within the extraction range of the section Contour correction.

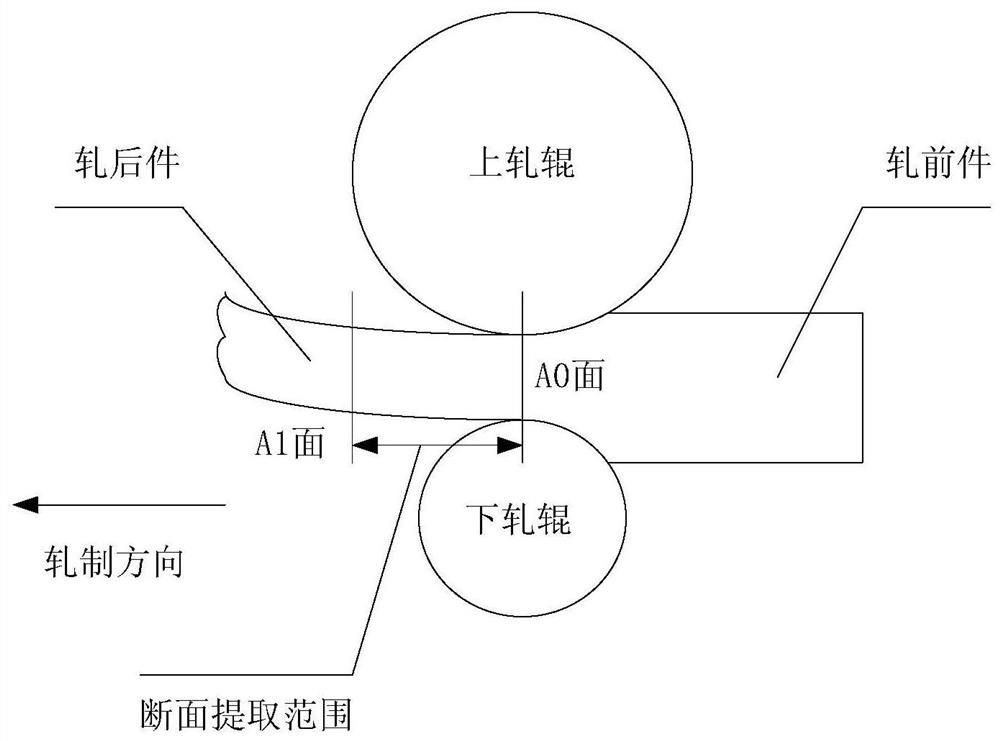

[0043] In the above method, see figure 1 Schematic diagram of the structure when the extraction range of the tapping section is determined. The specific method for determining the extraction range of the section includes the following steps:

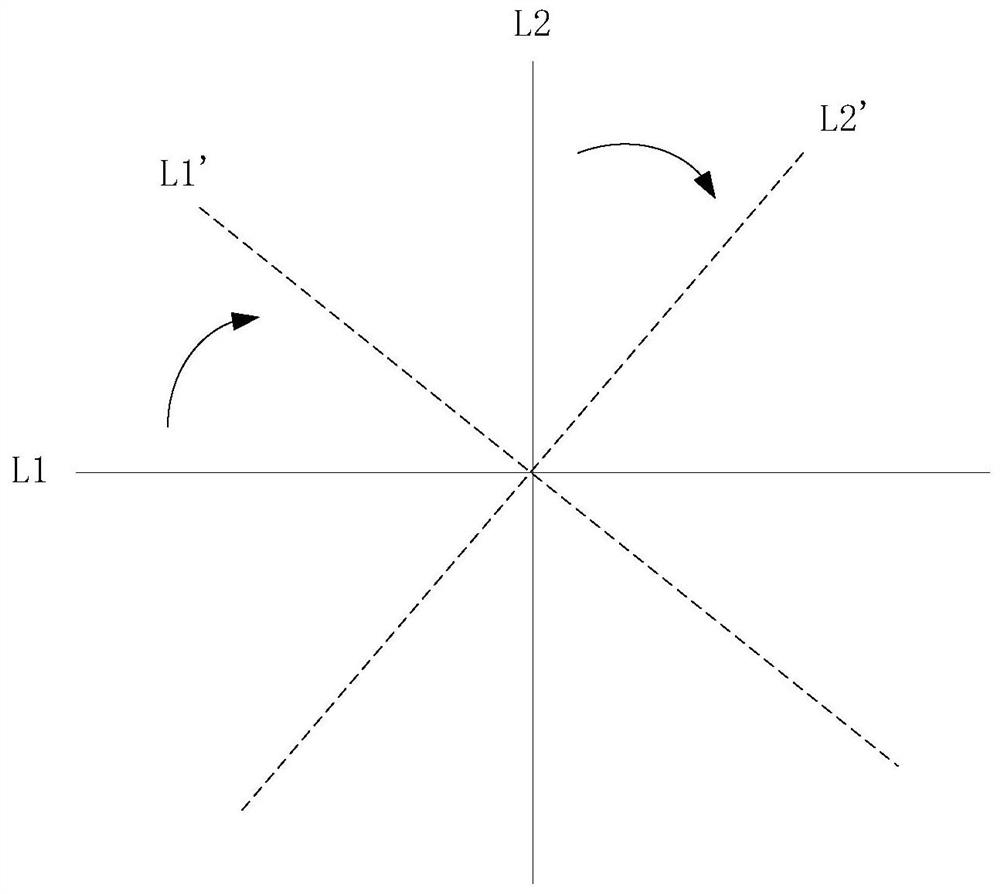

[0044] Step i, the straight line where the main shaft of the above roll or the lower roll is the X axis, the straight line where the vertical line between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com