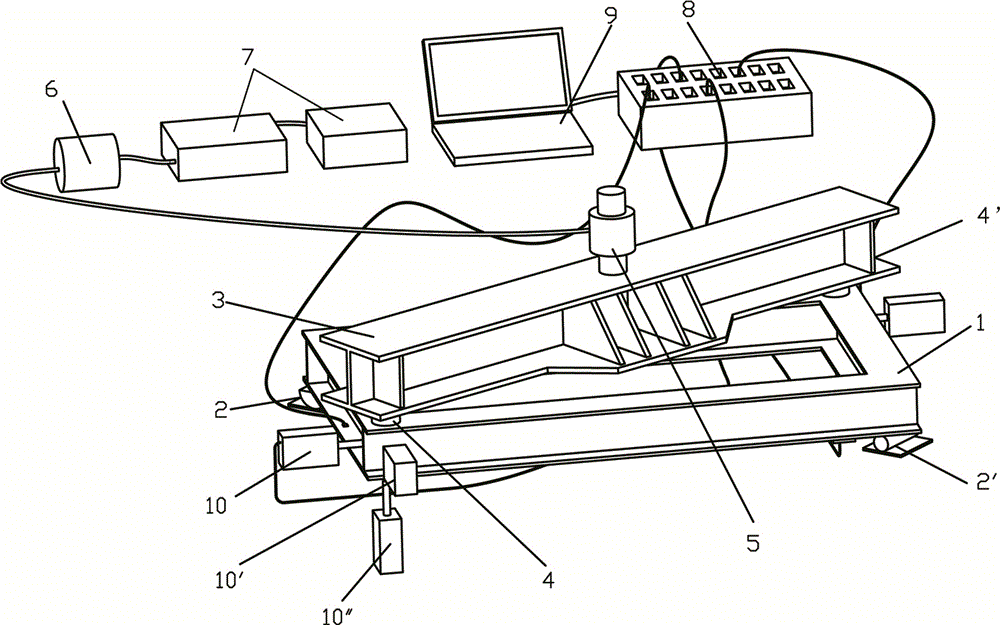

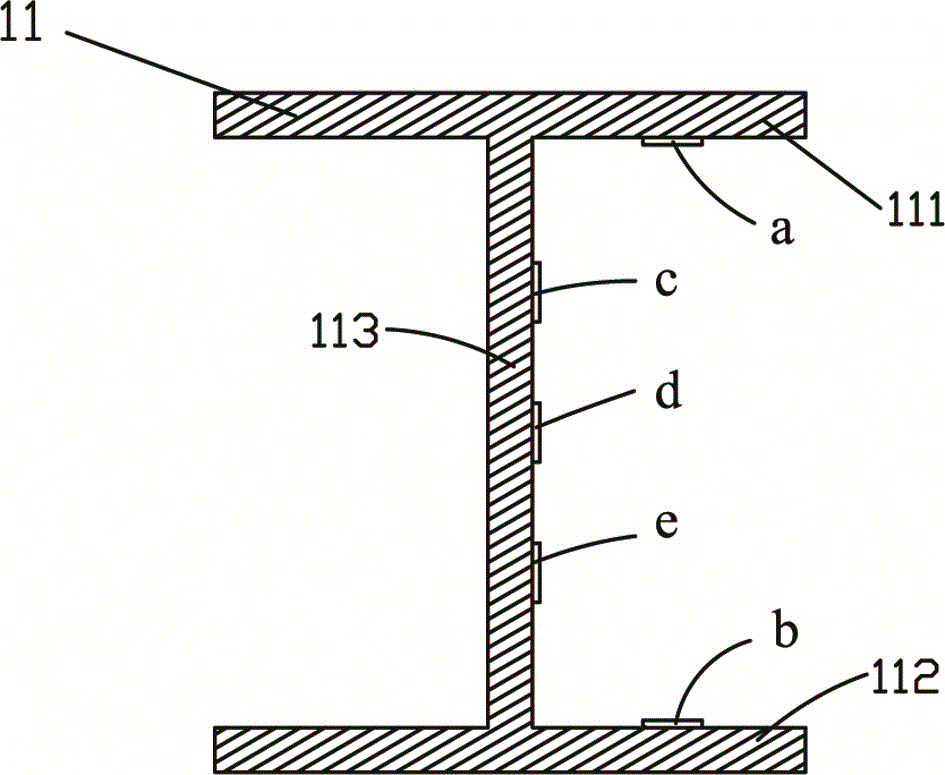

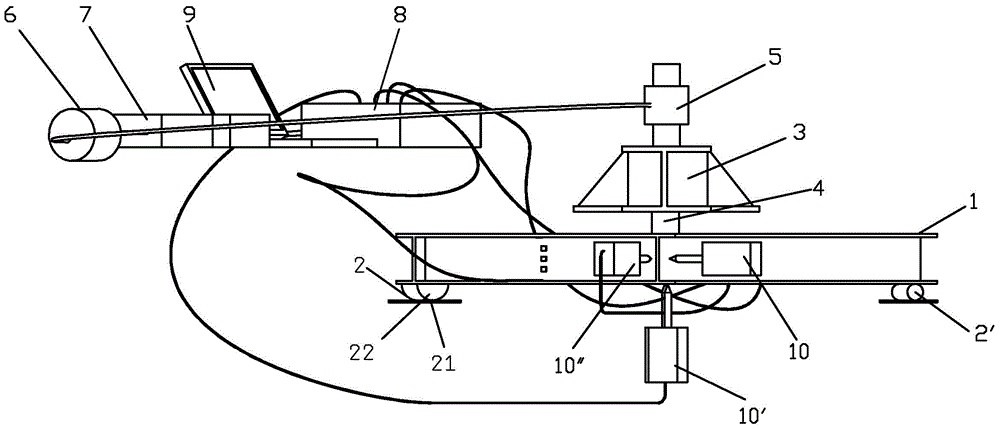

A method and device for testing the bending and torsion mechanical properties of an h-shaped girder frame

A testing method and testing device technology, applied in the field of automobile manufacturing, can solve the problems of undisclosed parts and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1: H-shaped girder frame-Q345 bending and torsion test

[0061] Using the test device to test the H-shaped girder frame-Q345 bending torsion test, under the load of 1KN, 2KN, 3KN, 4KN, 5KN, 6KN, 7KN, 8KN, 9KN, 10KN, the displacement changes of key parts, such as Figure 6 As shown, the strain changes in key parts, such as Figure 7 shown.

[0062] Figure 6 It shows that among the three directions, the Z-axis changes up to about 10mm, and the X-axis changes the least. Within 1mm, the maximum displacement of the Y-axis is less than 2mm.

[0063] Figure 7 It shows that the microstrain at the 10 strain test points changes linearly with the load, and the range of change is relatively small. The maximum tensile strain is 13με, and the maximum compressive strain is -19με.

Embodiment 2

[0064] Example 2: H-shaped girder frame-QSTE700 bending torsion test

[0065] Using the test device to test H-shaped girder frame-QSTE700 bending torsion test, under the action of 1KN, 1.5KN, 2KN, 2.5KN, 3KN, 3.5KN, 4KN, 4.5KN loading force, the displacement changes of key parts, such as Figure 8 As shown, the strain changes in key parts, such as Figure 9 shown.

[0066] Figure 8 It shows that the maximum change in Z axis is about 12mm, the change in X direction is the smallest, within 1mm, and the maximum displacement of Y axis is 2mm.

[0067] Figure 9 It shows that the microstrain at the 10 strain test points changes linearly with the load, the range of change is small, the maximum tensile strain is 24με, and the maximum compressive strain is -22με.

[0068] The method and device for testing the bending and torsion mechanical properties of the H-shaped girder frame by the present invention can be used to investigate the calculation of deformation, angle and displace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com