Axle gearbox wheel-to-axle box bearing test device

A technology of axle box bearings and test equipment, which is applied in the direction of mechanical bearing testing, etc., to achieve the effects of precise control, simple operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

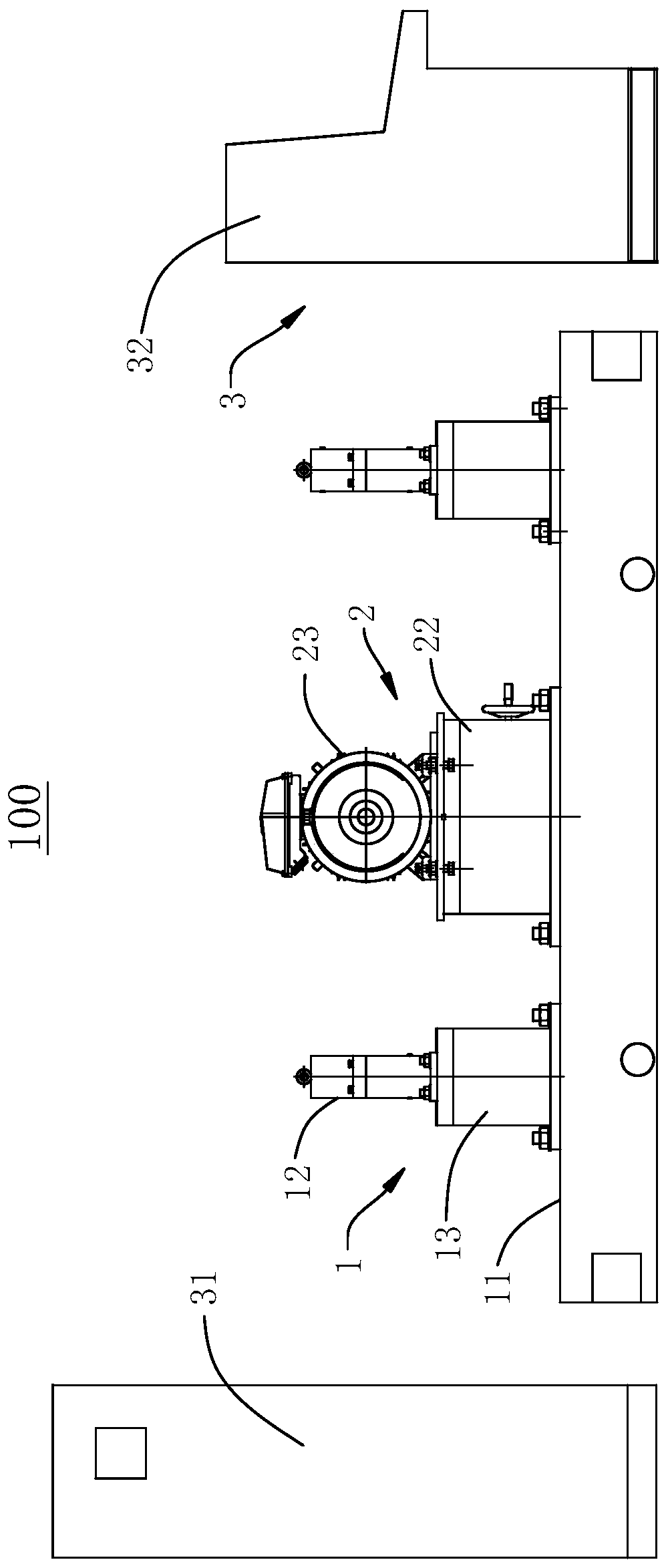

[0039] Please refer to figure 1 , this embodiment provides an axle gearbox wheel-to-axlebox bearing test device 100, which is mainly used in large-scale railway maintenance machinery, including a tooling fixing mechanism 1, a driving mechanism 2 and a control mechanism 3.

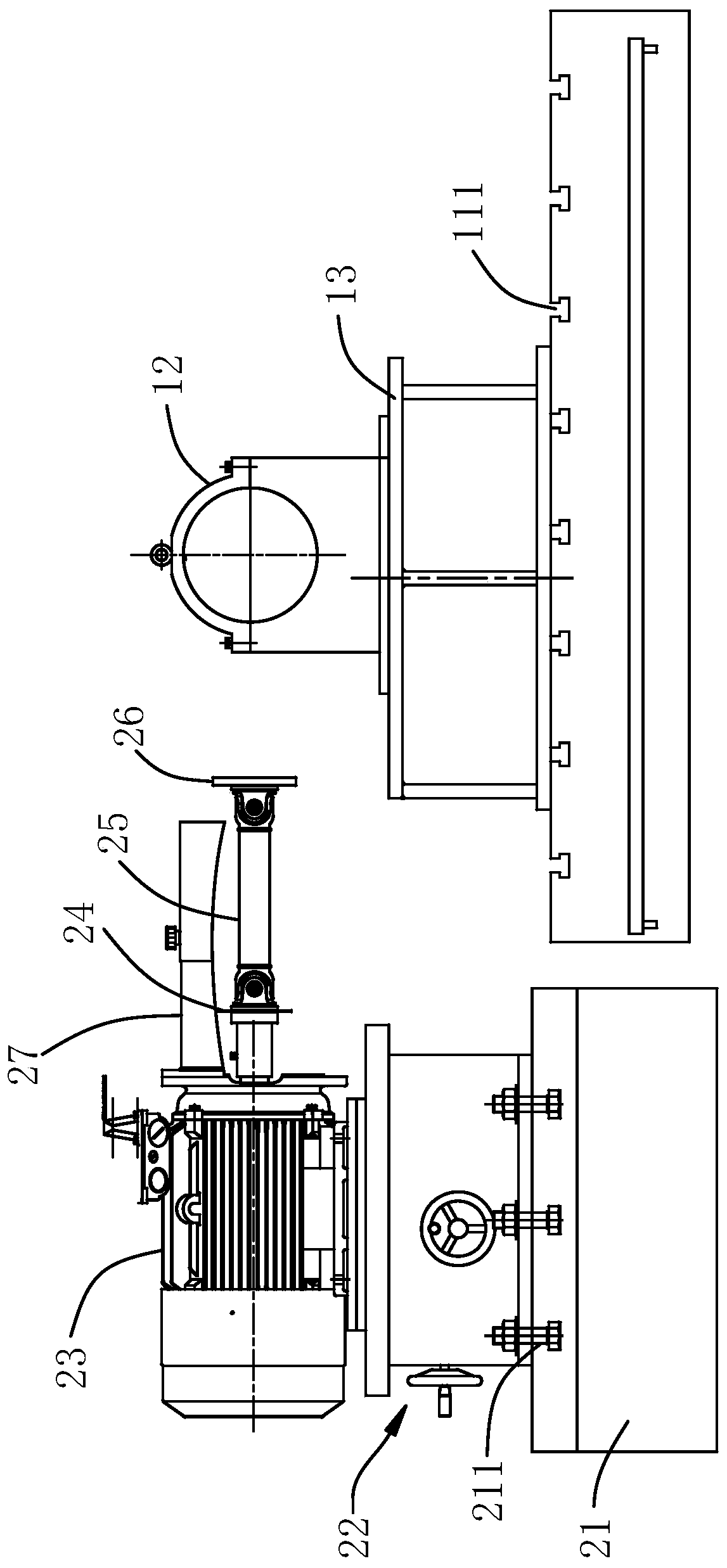

[0040] Such as Figure 1-Figure 9 As shown, in the present embodiment, the fixture fixing mechanism 1 includes a platform 11 and two test fixtures 12 installed on the platform 11, and the two test fixtures 12 are arranged at intervals for supporting the axle ends on both sides of the axle gearbox; Mechanism 2 includes a motor mounting base 21 and a motor adjustment seat 22 and a variable frequency motor 23 installed on the motor mounting base 21. The frequency conversion motor 23 is detachably connected with the motor mounting base 21 through the motor adjustment seat 22. When the motor adjustment seat 22 is released When connecting bolts with the motor mounting base 21, the motor adjustment seat 22 can mo...

no. 2 example

[0068] After research, researchers have found that the axle gearbox wheel-to-axlebox bearing test device 100 provided by the present invention, on the basis of the above-mentioned first embodiment, can also make the following optional other structural solutions, which are specifically described as follows:

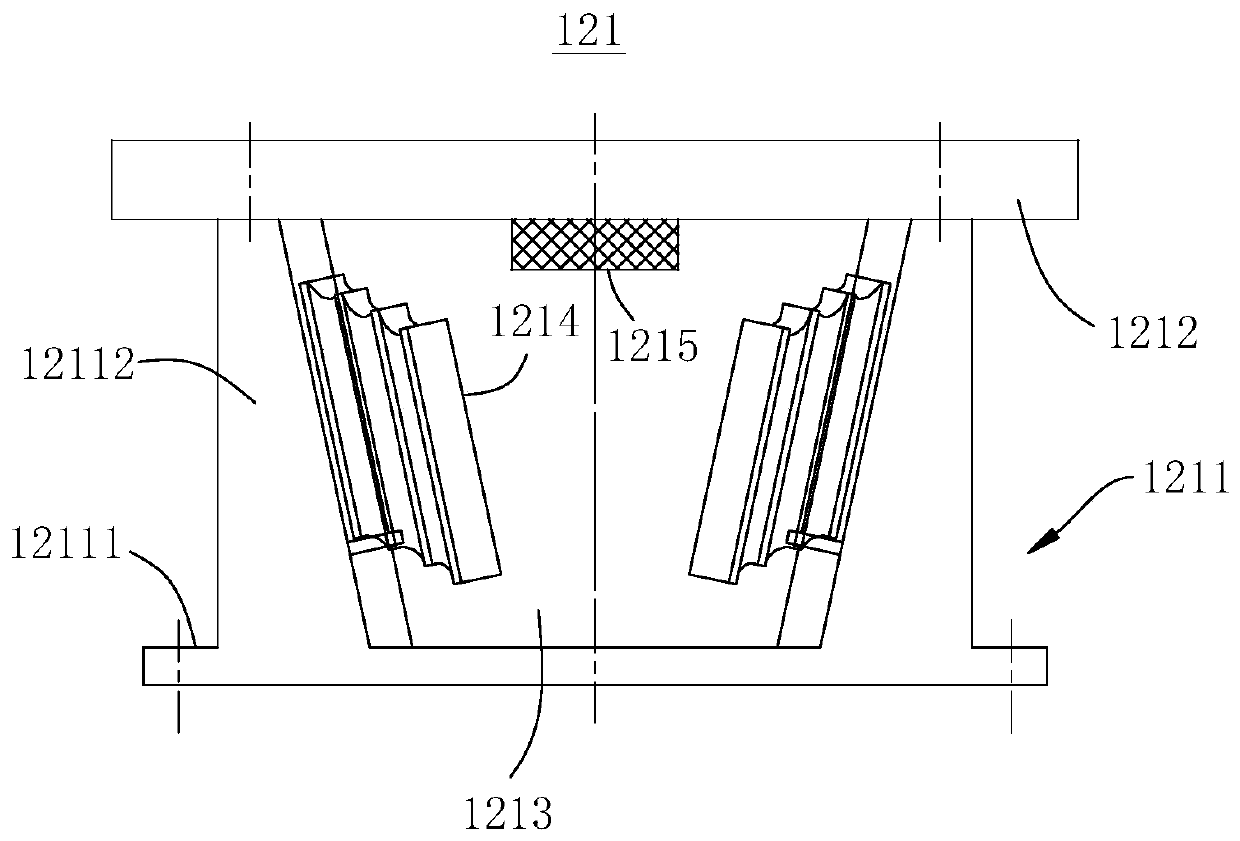

[0069] Such as Figure 10 As shown, the test fixture 12 includes a Harvard-type support 122, and the Harvard-type support 122 includes a Harvard-type base 1221 and a Harvard-type cover 1222 matched with the Harvard-type base 1221, and the Harvard-type cover 1222 and the Harvard-type base 1221 are connected by bolts , easy to install and disassemble; the Harvard-shaped base 1221 is provided with a semicircular first groove 12211, and the Harvard-shaped cover plate 1222 is provided with a second groove 12221 matching the first groove 12211, and the first groove 12211 is connected with the second groove 12211. The two grooves 12221 cooperate to form a cylindrical chamber 1223 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com