A method and device for detecting the aging performance of a lead-acid battery safety valve

A kind of technology of aging performance and lead-acid storage battery, applied in the direction of measuring device, mechanical valve test, mechanical component test, etc., can solve the problems of not being able to truly reflect the working condition of the safety valve, misjudgment, affecting battery life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

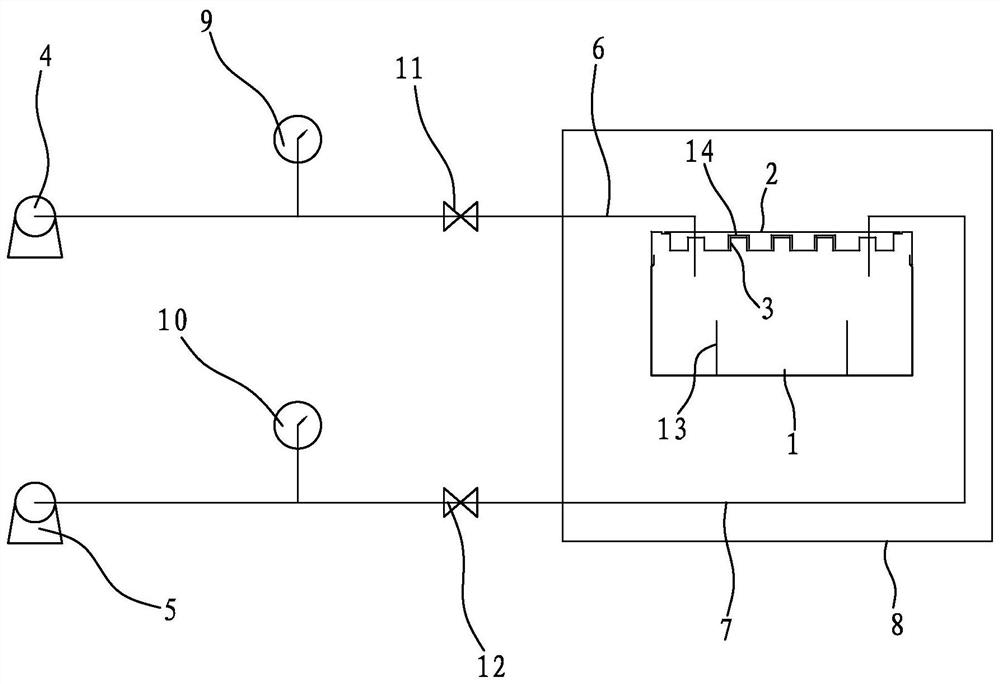

[0032] Such as figure 1 As shown, a device for testing the aging performance of the lead-acid battery safety valve includes: a battery tank, a compressed air source 4, a vacuum pump 5, an inflation tube 6 and an exhaust tube 7.

[0033] The compressed air source 4 is used to inflate the battery tank to maintain a positive pressure in the battery tank. Generally, the compressed air source 4 can use a steel cylinder with compressed air; the vacuum pump 5 is used to pump air to the battery tank to maintain a negative pressure in the battery tank. The compressed air source 4 and the vacuum pump 5 are switched to maintain positive and negative pressures in the interval of the battery tank, simulating the state of charging and discharging of the battery during actual use. The two ends of the inflation tube 6 are respectively connected to the compressed air source 4 and the battery tank; the two ends of the air extraction tube 7 are respectively connected to the vacuum pump 5 and the...

Embodiment 2

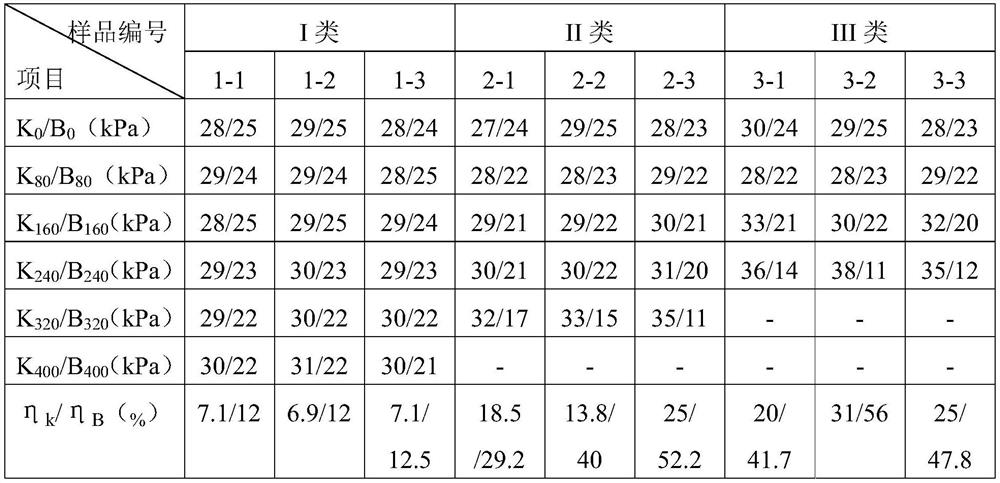

[0041] The device in Example 1 was used for detection. The temperature of the incubator was set at 45°C.

[0042] The detection method comprises the following steps:

[0043] (1) Detect the initial valve opening pressure and valve closing pressure of the safety valve sample, which are respectively K 0 and B 0 ;

[0044] (2) Install the safety valve sample on the valve seat of the empty battery tank cover filled with electrolyte, so that positive pressure and negative pressure are maintained in the empty battery tank in sequence. The positive pressure value is set to 20kPa, and the negative pressure value is Set to -10kP, one positive pressure and one negative pressure are one cycle, each positive pressure and negative pressure are maintained for 5 minutes respectively, and the valve opening pressure K of the safety valve sample is tested again after 80 cycles n and closing valve pressure B n ;

[0045] (3) Calculate the rate of change of valve opening pressure and valve cl...

Embodiment 3

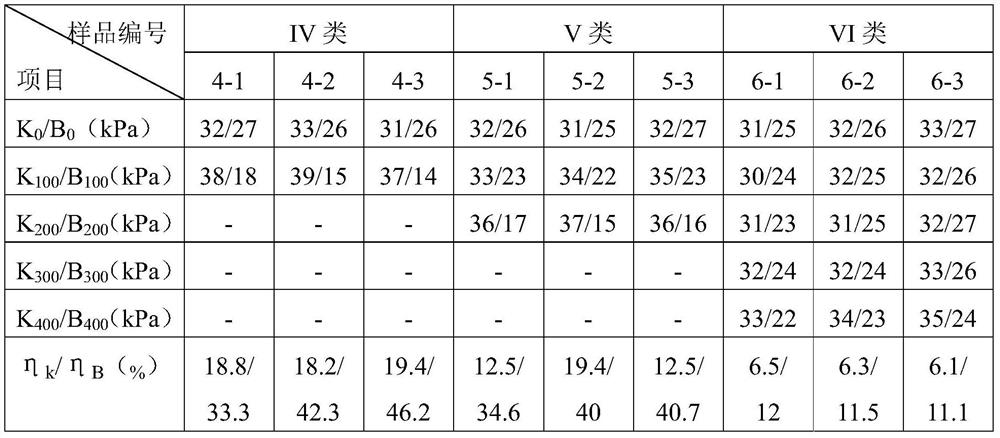

[0052] The device in Example 1 was used for detection. The temperature of the incubator was set at 55°C.

[0053] The detection method comprises the following steps:

[0054] (1) Detect the initial valve opening pressure and valve closing pressure of the safety valve sample, which are respectively K 0 and B 0 ;

[0055] (2) Install the safety valve sample on the valve seat of the empty battery tank cover filled with electrolyte, so that positive pressure and negative pressure are maintained in the empty battery tank in sequence. The positive pressure value is set to 45kPa, and the negative pressure value is Set to -20kPa, one positive pressure and one negative pressure are one cycle, each positive pressure and negative pressure are maintained for 2 minutes respectively, and the valve opening pressure K of the safety valve sample is tested again after 100 cycles n and closing valve pressure B n ;

[0056] (3) Calculate the rate of change of valve opening pressure and valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com