A twisted flexible cable for a robotic arm

A flexible cable and robot technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of easy deformation and fracture of cables, and achieve the effects of small friction coefficient, improved torsional performance, and high tensile strength

Active Publication Date: 2022-05-31

ANHUI LIANJIAXIANG SPECIAL CABLE

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The technical problem to be solved by the present invention is to provide a high tensile resistance, low friction coefficient for the problem that the cables in the prior art are easily deformed and broken in the high-speed movement, continuous bending and twisting and pulling force of the mechanical arm or drag chain system. , high torsion-resistant and high wear-resistant torsion flexible cable for robot arms

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Login to View More

Abstract

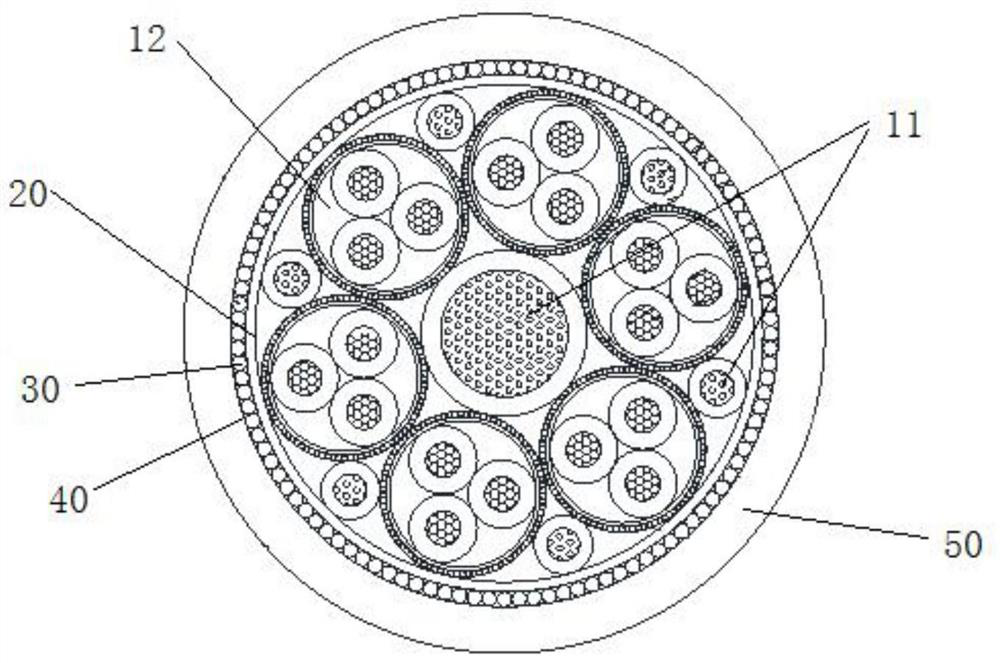

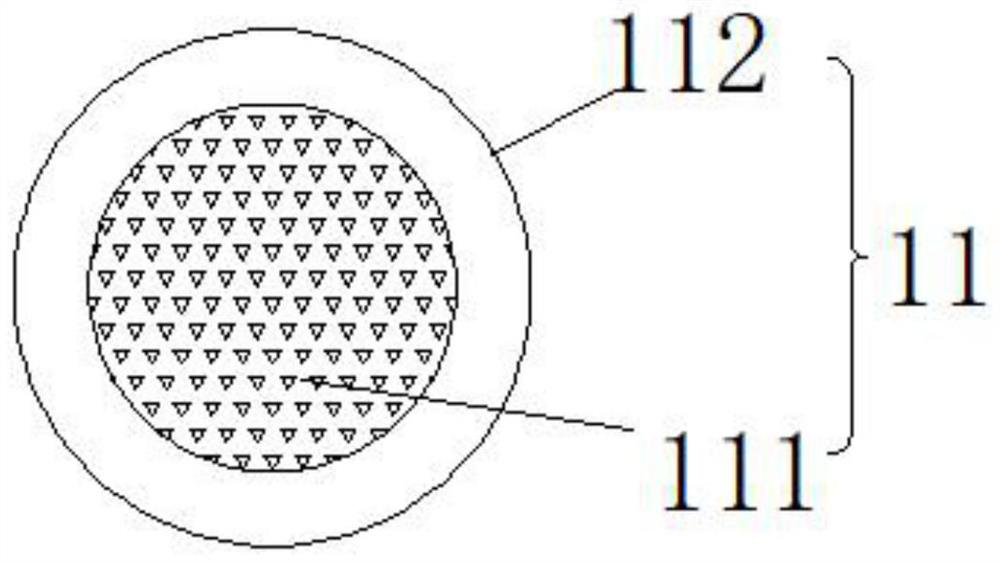

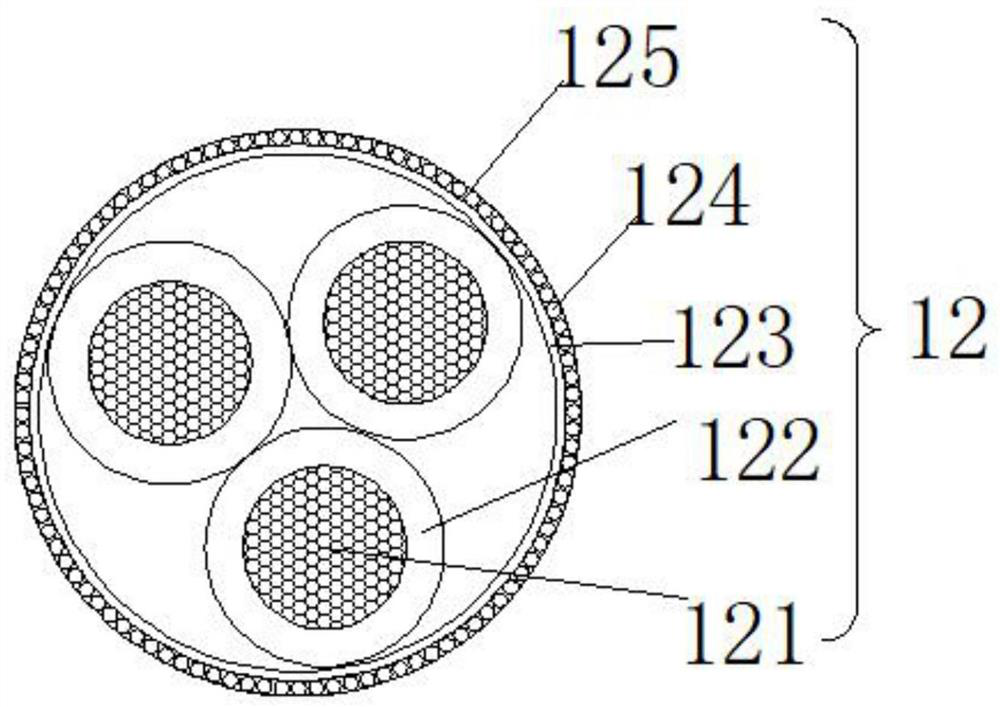

The invention discloses a twisted flexible cable for a robot arm. The flexible cable includes a cable core, and a first cladding layer made of polytetrafluoroethylene, which is sequentially coated on the outside of the cable core from inside to outside, The overall metal shielding layer made of copper-tantalum alloy wire winding, the second tape layer made of polytetrafluoroethylene and the outer sheath made of modified polytetrafluoroethylene material; the modified polytetrafluoroethylene The material is polytetrafluoroethylene as the base material, and polyether block amide is mainly added; the cable core includes multiple reinforcing cores and multiple three-wire assembly cores. The present invention provides a high tensile resistance, low friction coefficient, high torsion resistance and high wear resistance for high-speed movement, continuous bending and twisting, and the prior art cables are easily deformed and broken by the pulling force of the mechanical arm or towline system. Twisted flexible cables for robotic arms.

Description

A torsion flexible cable for robotic arm technical field The present invention relates to the technical field of cables for robots, more specifically, to a torsion soft cable. Background technique [0002] Intelligent manufacturing: This is a man-machine integrated intelligent system composed of intelligent machines and people. Intelligence is manufacturing The development direction of automation. In addition to being widely used in the manufacturing field, robots are also used in resource exploration and development, disaster relief and insurance, medical services, home, entertainment, military and aerospace and other fields. Robots are an important production and Service equipment is also an indispensable automation equipment in the field of advanced manufacturing technology. In many manufacturing fields, applied engineering The most widespread field of industrial robots is the automobile and auto parts manufacturing industry. Auto and Auto Parts in the Americ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01B7/02H01B7/04H01B7/17H01B7/18

CPCH01B7/04H01B7/18H01B7/17H01B7/0216

Inventor 黄冬莲

Owner ANHUI LIANJIAXIANG SPECIAL CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com