A vacuum glue filling method and a vacuum glue filling machine

A technology of glue filling machine and vacuum, which is applied in the field of vacuum glue filling method and vacuum glue filling machine, which can solve the problems of low production efficiency, inaccurate measurement, uncertain pipeline pressure, etc., so as to save time and achieve good glue filling effect , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

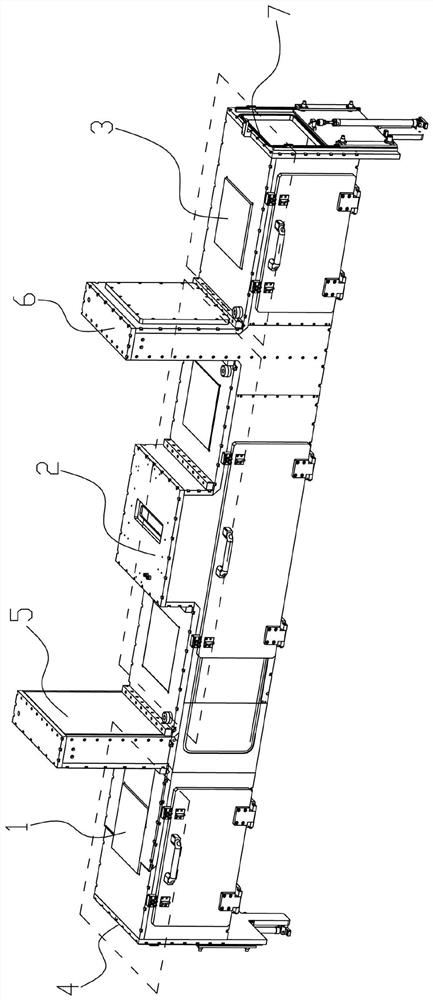

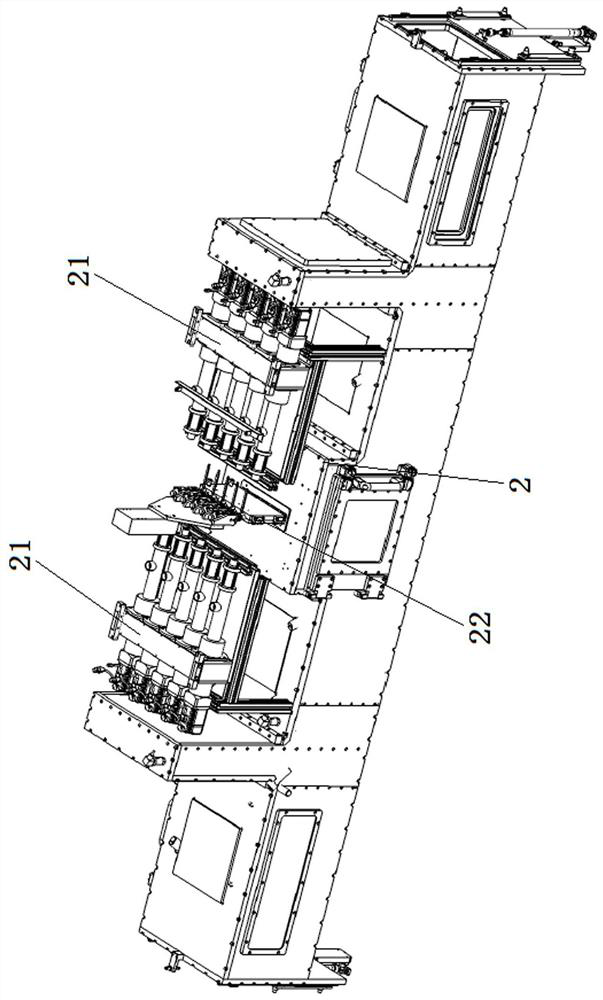

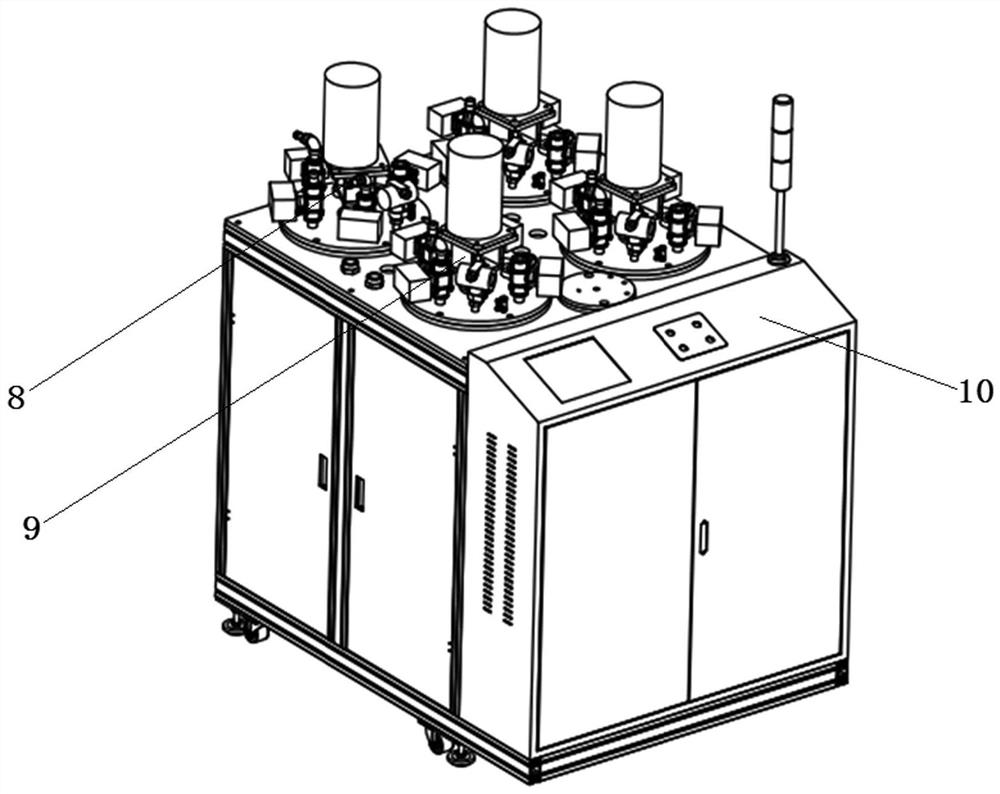

[0051] like figure 1 As shown, the vacuum filling method proposed in the embodiment of the present invention includes the following steps:

[0052] S1. After the product enters the pre-extraction box, door one and door two are closed to vacuumize the pre-extraction box, and then door three is closed to vacuumize the working box;

[0053] S2. After the negative pressure in the pre-pumping box and the working box is balanced, the second door is opened, the product one enters the working box from the pre-pumping box, and then the second door is closed;

[0054] S3. Product 1 begins to pour glue in the working box; at the same time, when the door is opened, the pre-pumping box is evacuated, and then product 2 is put in, then door 1 is closed, and the pre-pumping box is evacuated again; door 4 is closed, and the exhaust Vacuumize the air box. After the negative pressure balance between the exhaust box and the working box and the processing of the product in the working box is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com