Automatic vehicle-mounted steel pipe unloading device

A technology for automatic unloading and steel pipes, which is applied to vehicles with swing arms, manipulators, chucks, etc., and can solve problems such as lack of pressure sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

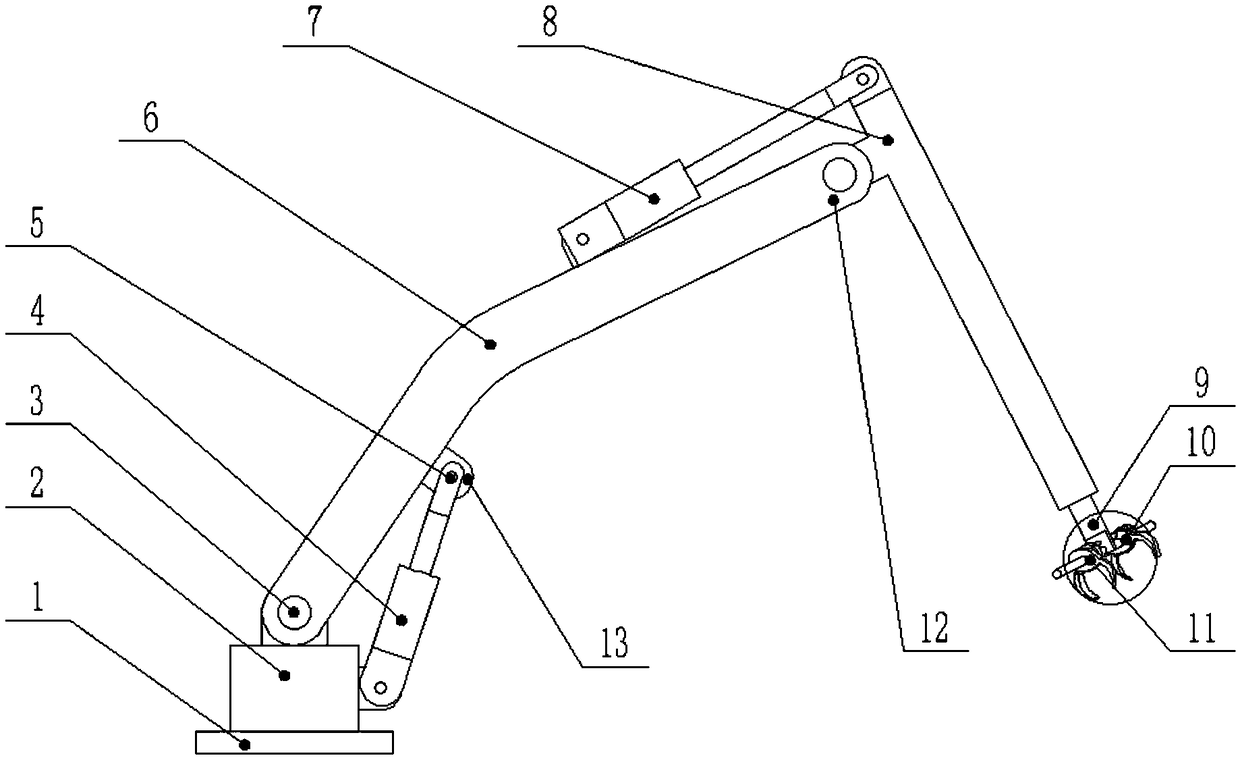

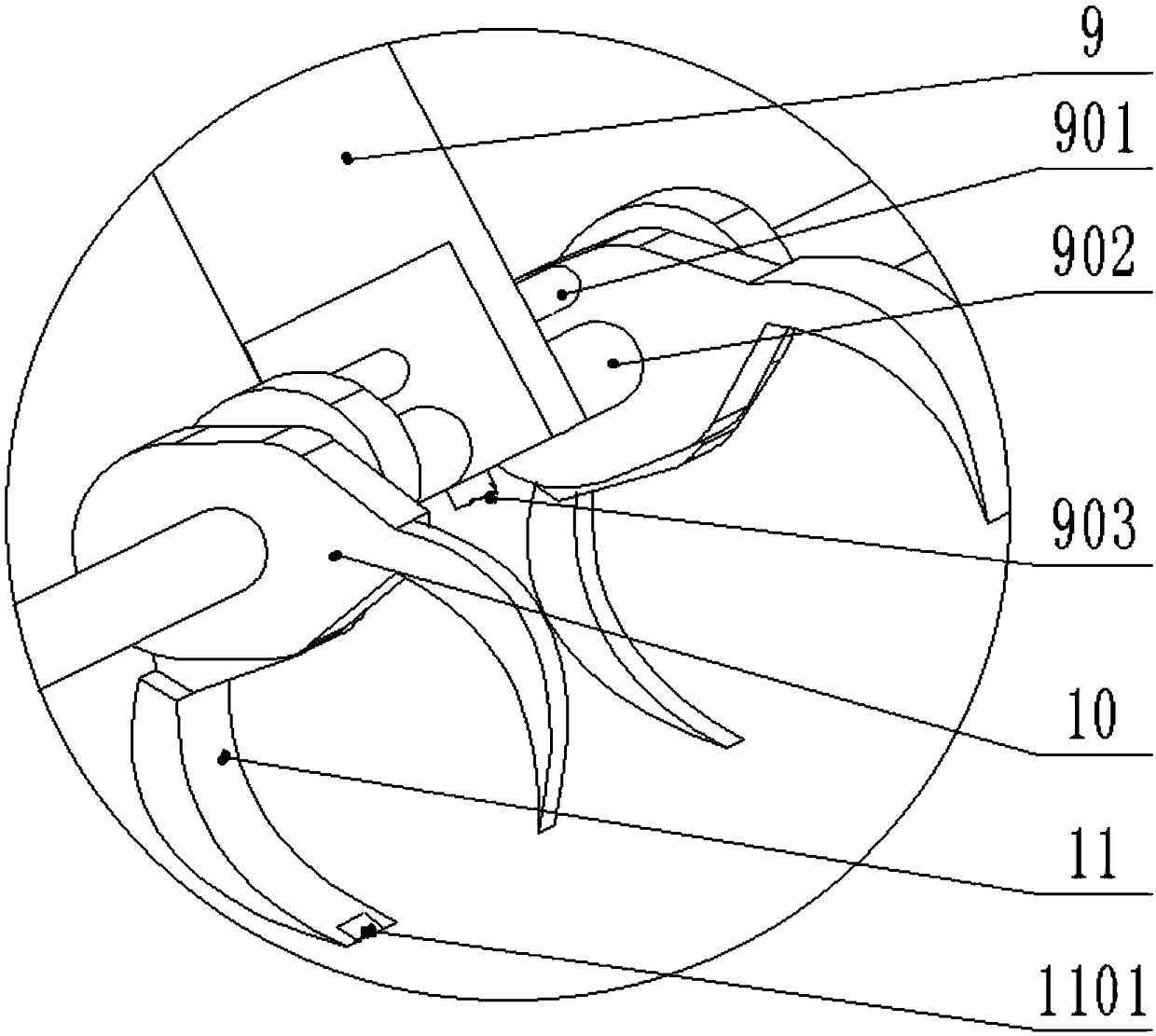

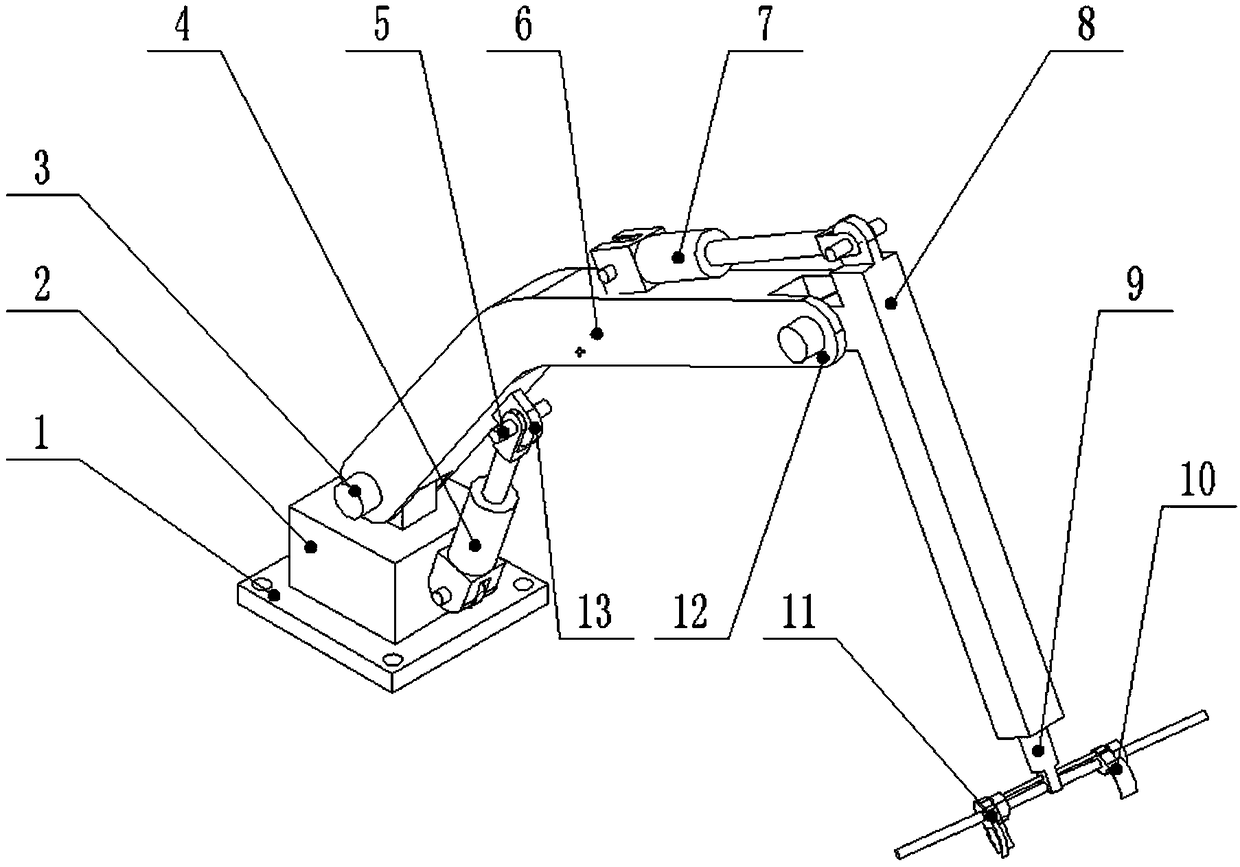

[0017] A vehicle-mounted automatic unloading steel pipe device is composed of a base 1, a turntable 2, a mechanical arm 6, a rotating arm 8, an upper hydraulic cylinder 7, a lower hydraulic cylinder 4, a thin connecting pin 5, a thick connecting pin 3, a steering gear 9, and a small steel pipe Composed of pliers 10 and large steel pipe tongs 11, it is characterized in that the turntable 2 has a structure of a disc and a connecting rib 13, and is connected to the base 1 through the lower disc, and the connecting rib 13 on the side of the turntable is connected to the lower hydraulic cylinder. 4 are connected by the thin connecting pin 5, and the upper connecting rib 13 is connected with the mechanical arm 6 by the thick connecting pin 3. The two ends of the mechanical arm 6 have two connecting rings 12 respectively, which are connected with the rotating disk 2 and the rotating arm 8. The connecting ribs 13 are matched and connected by the thick connecting pin 3. There are two co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com