Electric valve and refrigerating cycle system using the electric valve

A technology of electric valves and valve housings, which can be used in fluid circulation arrangements, lifting valves, refrigerators, etc., and can solve problems such as difficult access to valve seats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

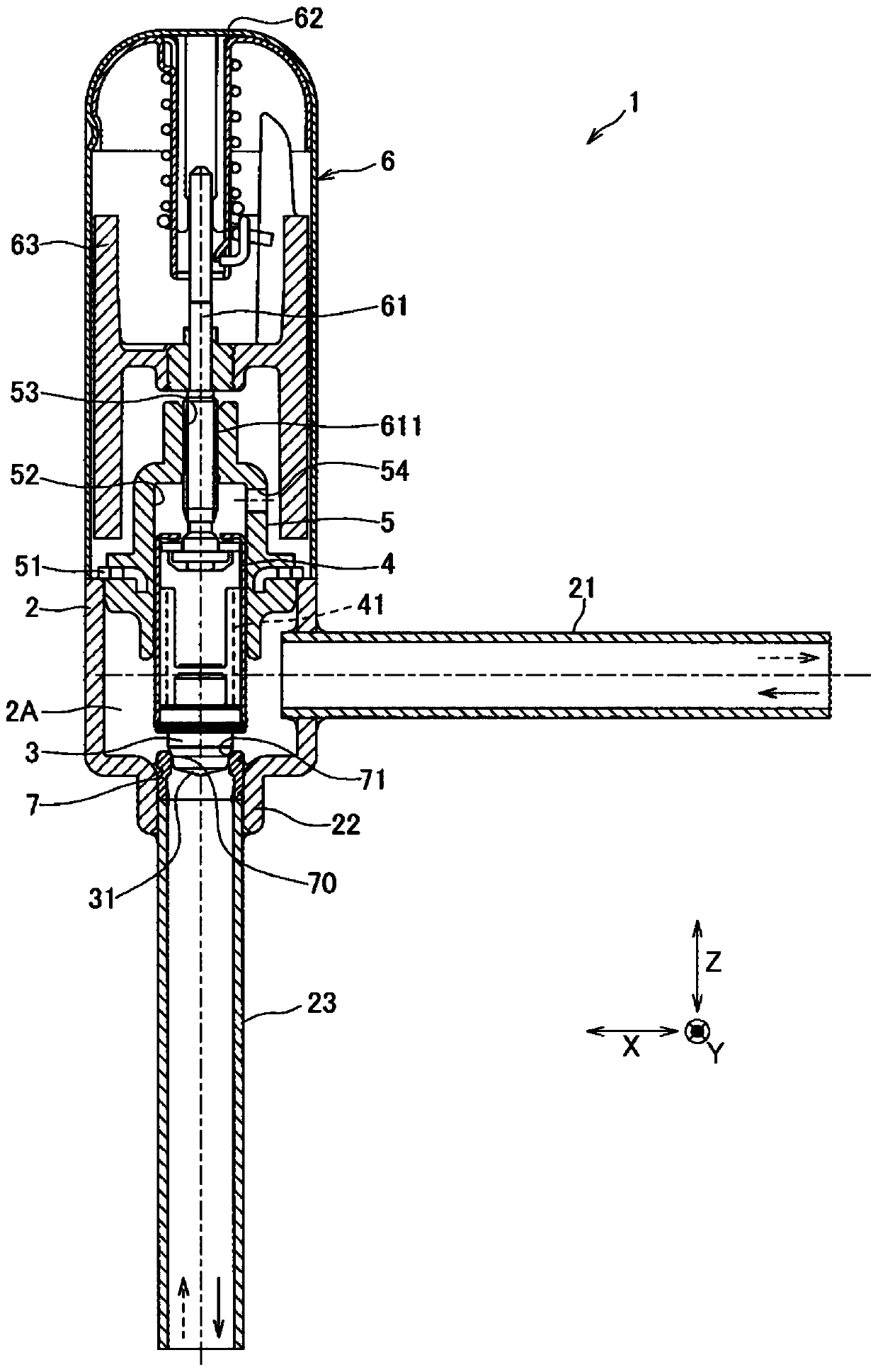

[0025] Hereinafter, each embodiment of the present invention will be described based on the drawings. Such as figure 1 As shown, the electric valve 1 of this embodiment is used in refrigeration cycle systems of air conditioners such as combined air conditioners and indoor air conditioners, and includes a valve casing 2 , a valve core 3 , a valve frame 4 , a support member 5 , and a stepping motor 6 . In this embodiment, the operating direction of the spool 3 is referred to as the Z direction, and two directions approximately perpendicular to the Z direction are referred to as the X direction and the Y direction, respectively.

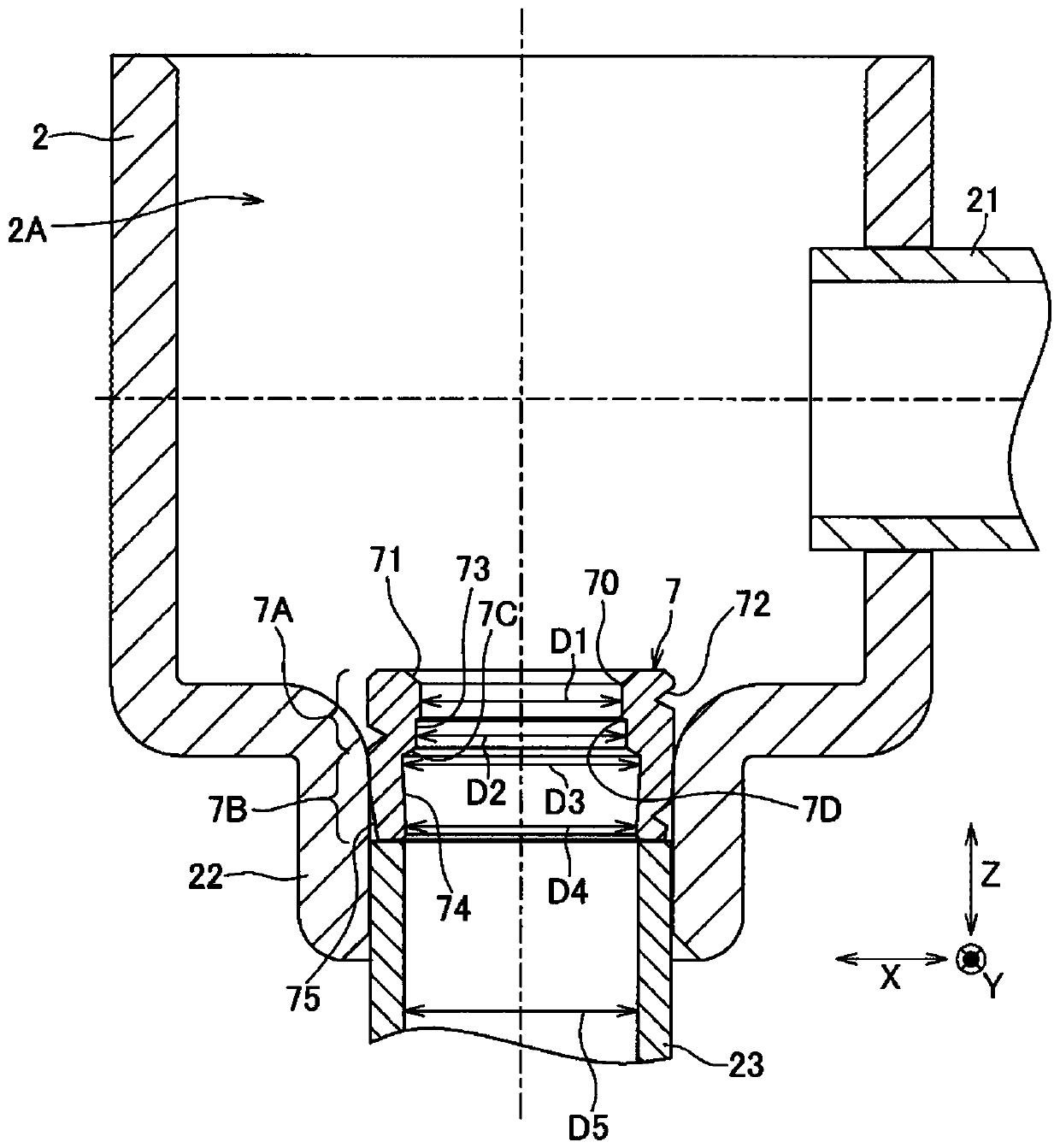

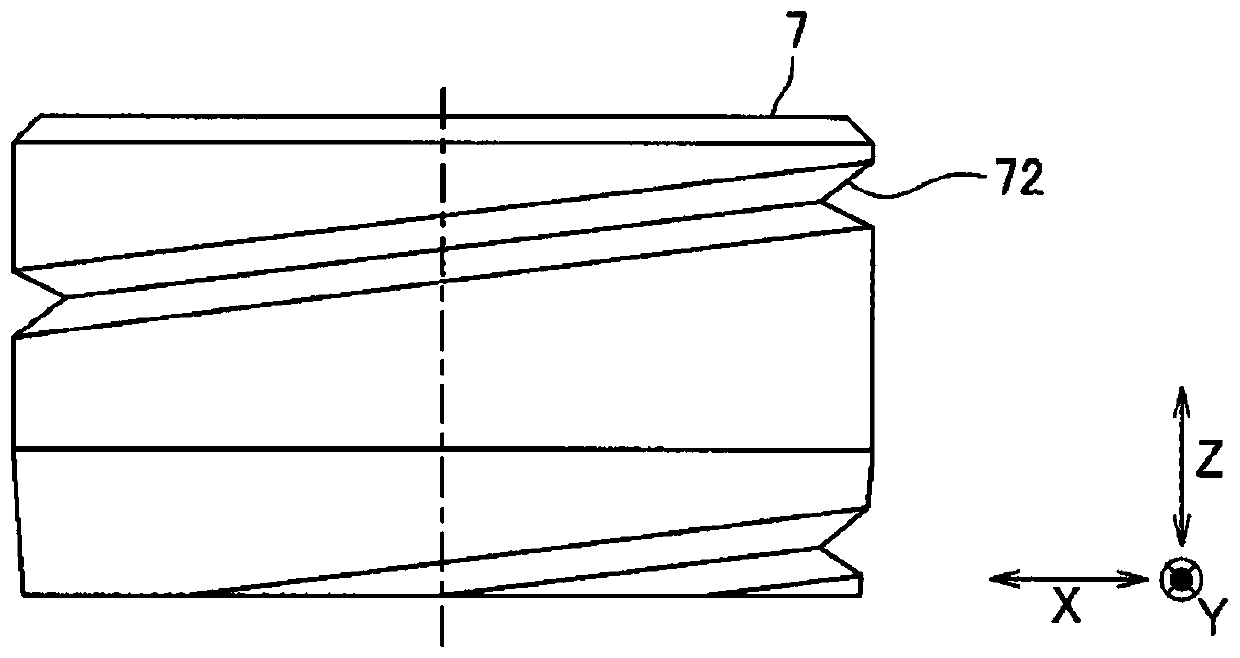

[0026] The valve casing 2 is formed in a cylindrical shape extending in the Z direction, and accommodates the valve body 3 and the valve frame 4 in the valve chamber 2A inside. Further, a joint pipe 21 communicating with the valve chamber 2A and extending in the X direction is attached to a side surface of the valve housing 2 , and a cylindrical openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com