Manufacturing and usage methods of membrane taking device for TSP (Total Suspended Particulates) collector with PM5 and PM2.5 sampling heads

A collector and sampling head technology, applied in the field of environmental protection equipment, can solve the problems of ring filter membrane deformation, difficult ring filter membrane removal, rupture, etc., to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

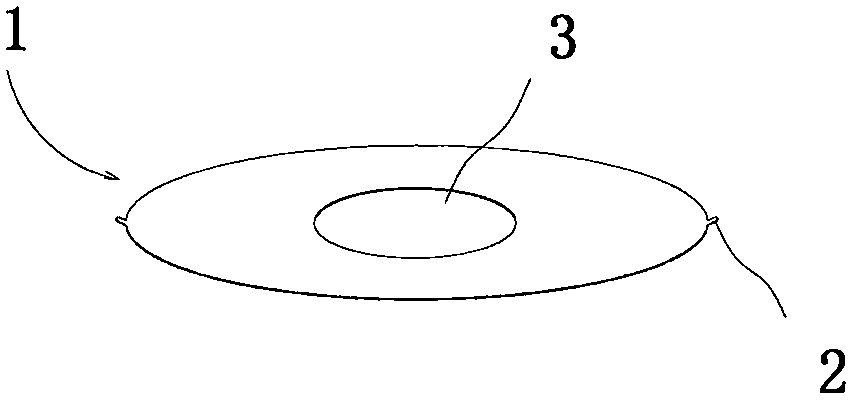

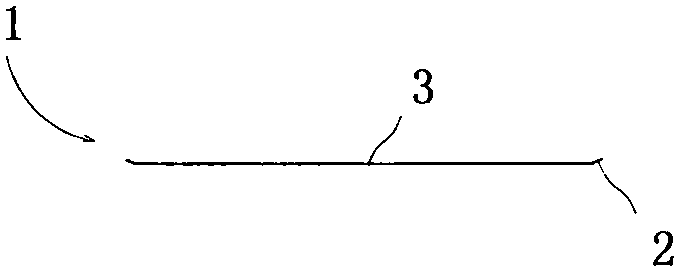

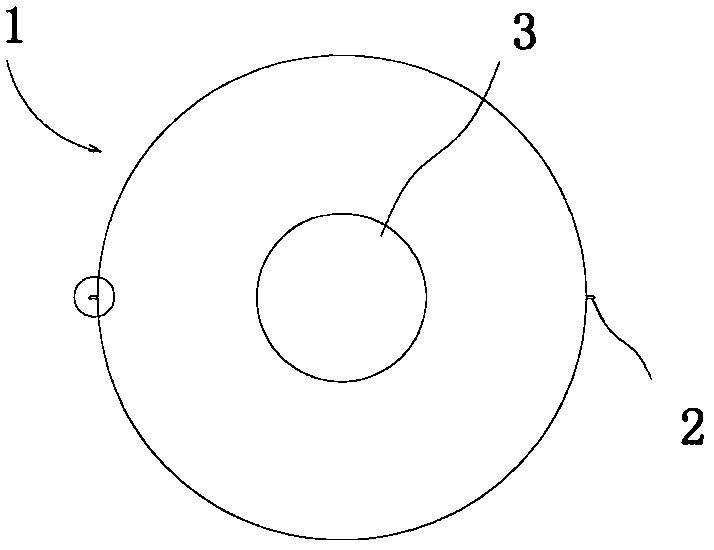

[0029] A kind of PM5 that the present invention relates to, PM2.5 sampling head TSP collector film taking device such as figure 1 , figure 2 , image 3 shown. It mainly includes an annular filter membrane support plate 1 and two tweezers 2 extending from the annular filter membrane support plate 1 on the outer arc edge of the annular filter membrane support plate 1 .

[0030] The shape and size of the annular filter membrane supporting plate 1 are consistent with the shape and size of the bottom plane of the annular groove 8 of the PM5, PM2.5 sampling head TSP collector, and its material is film, and the film thickness is set to 0.2 mm to 0.4 mm .

[0031] The two tweezers ears 2 are extensions of the annular filter membrane supporting plate 1, which are symmetrically arranged on the outer arc edge of the annular filtering membrane supporting plate 1, and are shaped as strips with a width of 1.5 mm and a length of 2.5 mm to 3.5 mm.

[0032] A circular arc gap 4 with a ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com