Preparation method for magnetic adsorption material for adsorbing heavy metals and application of magnetic adsorption material

A technology for magnetic adsorption material and heavy metal adsorption, applied in the field of soil pollution and remediation, can solve the problems of poor treatment effect of various heavy metals, non-reusable, and high restoration cost, and achieves the ability to enhance the ability to extract heavy metals and promote the coordination effect. ability, the effect of improving water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Dissolve 10g of carboxymethyl chitosan in 200ml of water to form an aqueous solution, then add 10g of activated carbon powder, 10g of oleic acid-wrapped magnetic ferric iron tetroxide nanoparticles and 5g of glutaraldehyde crosslinking agent to the aqueous solution, stir well and then add Sodium hydroxide solution, adjust the pH value to 12, place the reaction system in constant temperature water at 60°C for constant temperature crosslinking reaction for 7 hours, then add ethanol aqueous solution to the reaction product, separate solid and liquid, and wash the product with water and absolute ethanol five times After drying, grinding and sieving, the magnetic adsorption material can be obtained.

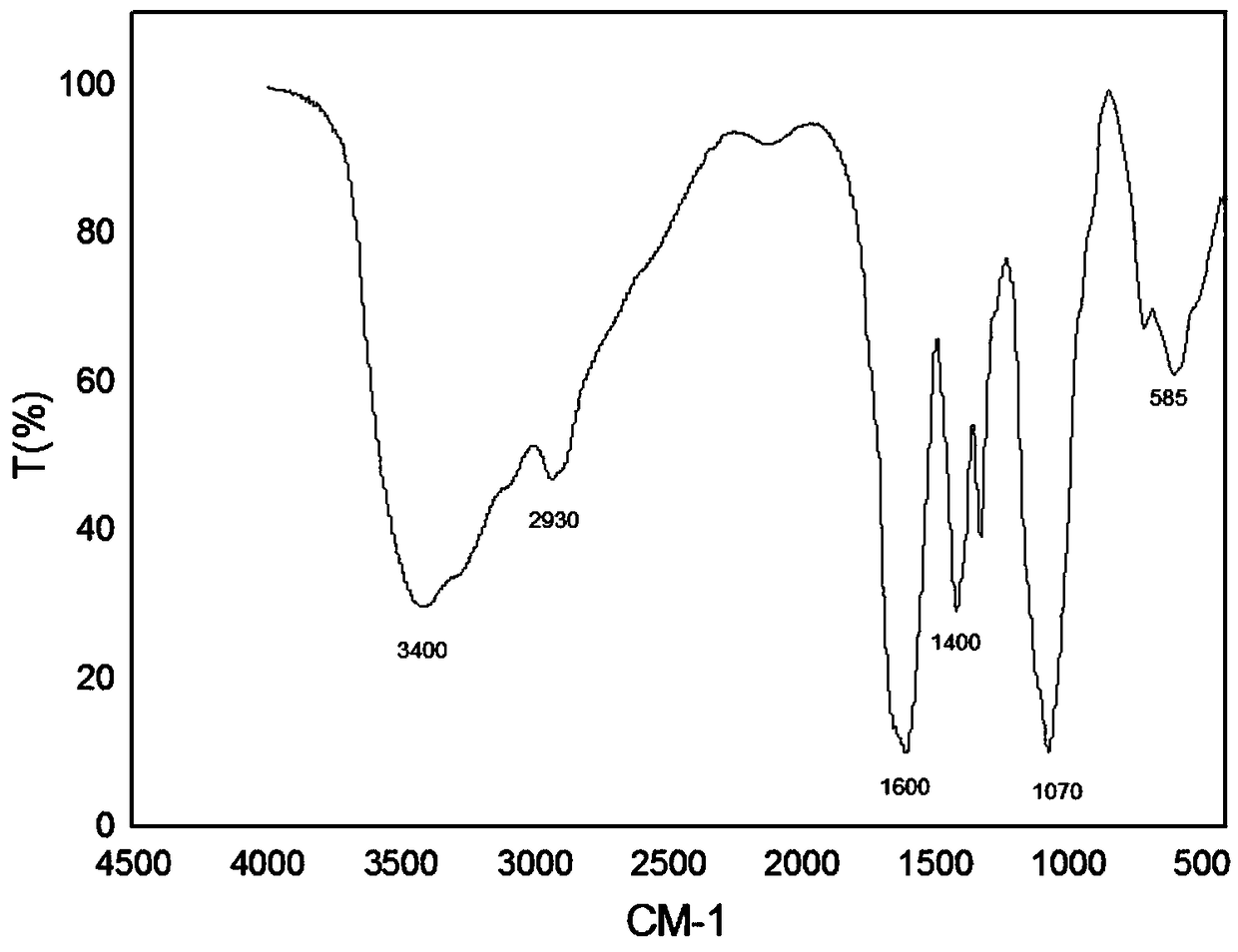

[0030] We carried out FT-IR test on the obtained magnetic adsorption material, the results are as follows: figure 1 shown, from figure 1 It can be seen that 1600cm -1 The characteristic peak is C=O bond, 1070cm -1 The absorption peak at CH is 2 The characteristic absorption...

Embodiment 2

[0033] Dissolve 10g carboxymethyl chitosan in 200ml water to form an aqueous solution, then add 50g activated carbon powder, 30g oleic acid-wrapped magnetic iron ferric oxide nanoparticles and 25g glyoxal cross-linking agent to the aqueous solution, stir well and add Sodium hydroxide solution, adjust the pH value to 10, place the reaction system in constant temperature water at 90°C for constant temperature crosslinking reaction for 12 hours, then add ethanol aqueous solution to the reaction product, separate solid and liquid, and wash the product five times with water and absolute ethanol After drying, grinding and sieving, the magnetic adsorption material can be obtained.

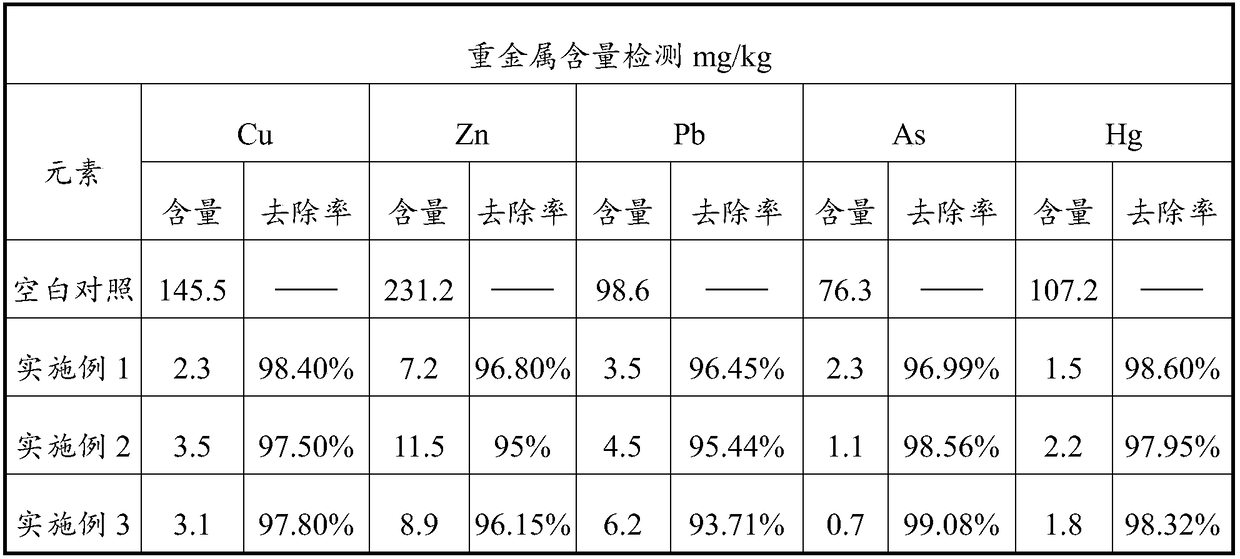

[0034] In order to verify the technical effect of the magnetic adsorption material obtained in Example 2, we applied the material obtained in Example 2 to heavy metal-contaminated soil, and added 0.1 kg of magnetic adsorption material to 1 kg of wet weight soil, mixed thoroughly, and the adsorption time wa...

Embodiment 3

[0036] Dissolve 10g of carboxymethyl chitosan in 200ml of water to form an aqueous solution, then add 30g of activated carbon powder, 50g of oleic acid-wrapped magnetic ferric iron tetroxide nanoparticles and 30g of epichlorohydrin crosslinking agent to the aqueous solution, and stir thoroughly Add sodium hydroxide solution, adjust the pH value to 9, place the reaction system in constant temperature water at 80°C for constant temperature crosslinking reaction for 5 hours, then add ethanol aqueous solution to the reaction product, separate solid and liquid, and wash the product with water and absolute ethanol for five After drying for a few times, the magnetic adsorption material can be obtained by grinding and sieving.

[0037] In order to verify the technical effect of the magnetic adsorption material obtained in Example 3, we applied the material obtained in Example 3 to heavy metal-contaminated soil, and added 0.01 kg of magnetic adsorption material to 1 kg of wet weight soi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap