A method for reducing the bubble rate of qfn chip welding and its steel mesh structure

A technology of chip welding and bubble rate, applied in welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as functional failure and affecting the reliability of solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Apparently, the drawings in the following description are only some embodiments of the present invention, and those skilled in the art can also obtain other implementation manners according to these drawings without creative efforts.

[0055]In an embodiment of the invention, a method for reducing the bubble rate of QFN chip soldering comprises the following steps:

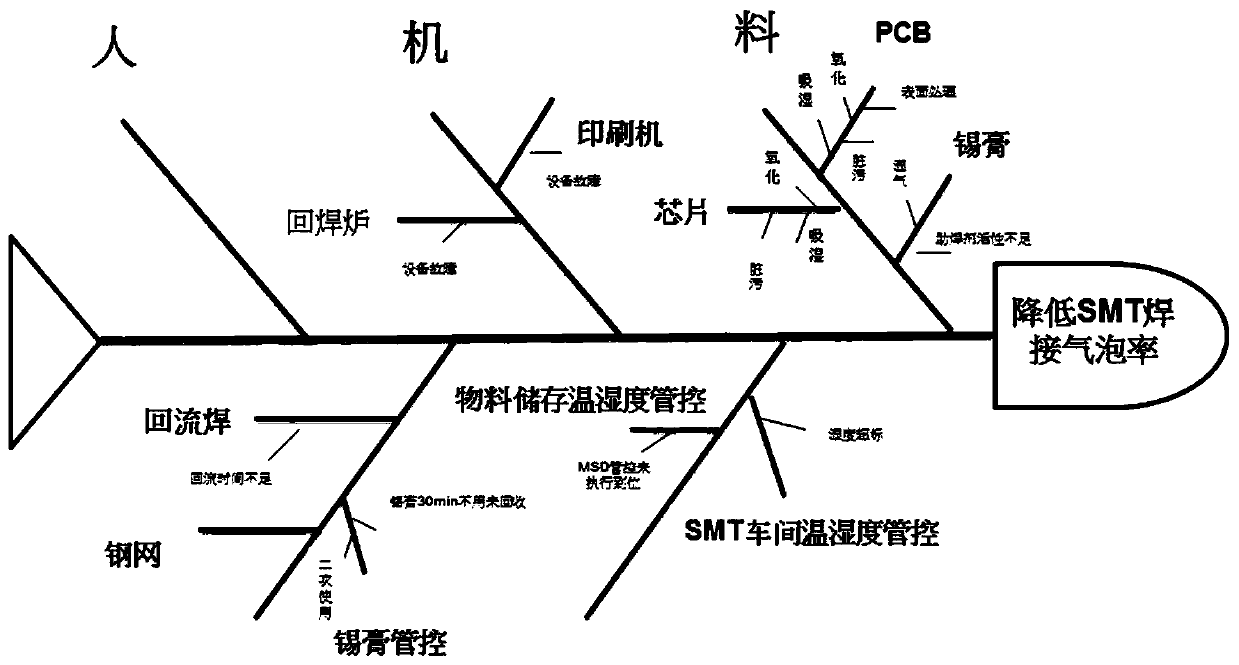

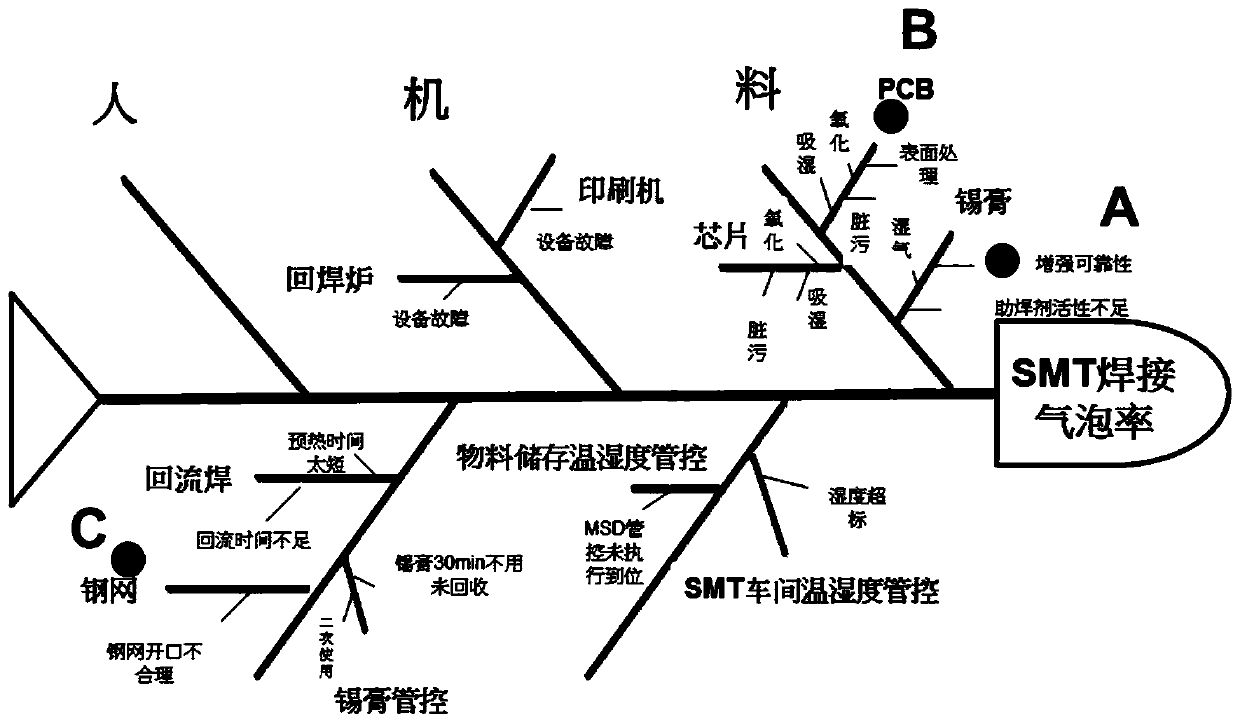

[0056] S01: judge the factors that generate the bubble rate, and obtain several main factors;

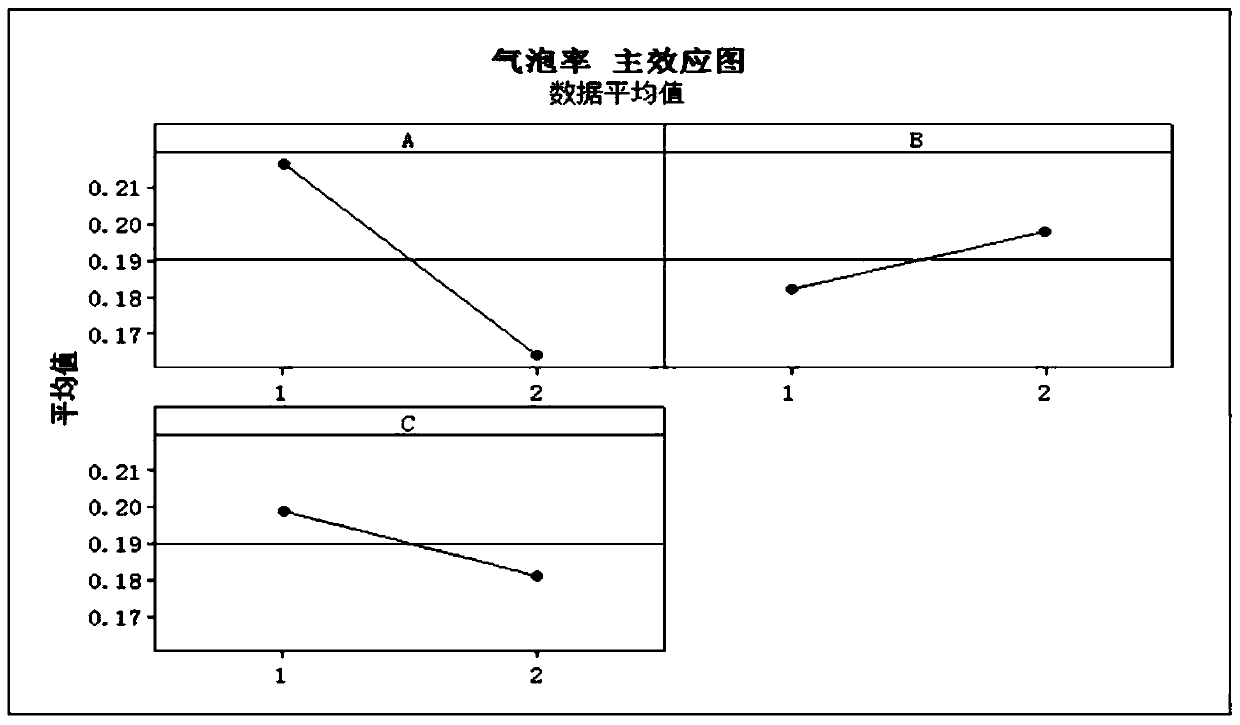

[0057] S02: According to several factors, each factor gives two different first fixed data respectively;

[0058] S03: Each factor in several factors selects a first fixed data respectively, forms the first test group, obtains the bubble rate value of corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com