Movable type gripping robot

A robot and mobile technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of difficult operation, inaccurate grasping range, low efficiency, etc. Take a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

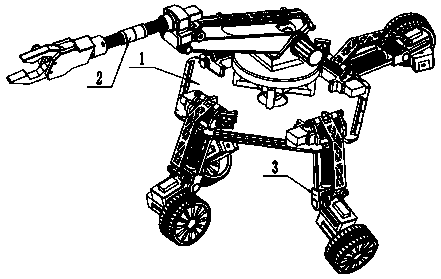

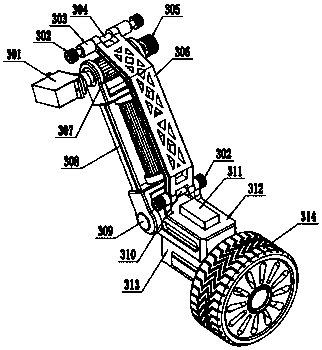

[0015] Example figure 1 , figure 2 , image 3 , Figure 4 As shown, a mobile grabbing robot includes: a main installation chassis 1, a grabbing unit 2, and a walking unit 3. It is characterized in that: the main installation chassis 1 is rhombus-shaped and has a circular hole in the middle, and the grabbing unit 2 through the circular hole and connected with the main installation chassis 1; there are protruding mounting seats near the four vertices of the rhombus chassis, and the traveling unit 3 is installed on the protruding mounting seat of the main mounting chassis 1, and the four traveling units 3 axis The adjacent angle is 90°.

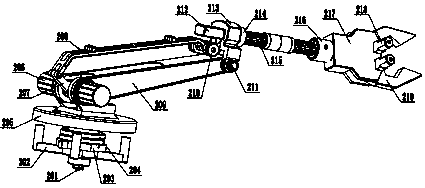

[0016] The further described mobile grabbing robot is characterized in that: the grabbing unit 2 includes: a turntable reducer 201, a turntable motor base 202, a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com