Roll paper side edge sealing and packing device

A technology of side sealing and rolling paper, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problem of operator burns, and achieve the effect of avoiding injury and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following is a further detailed description through specific implementations:

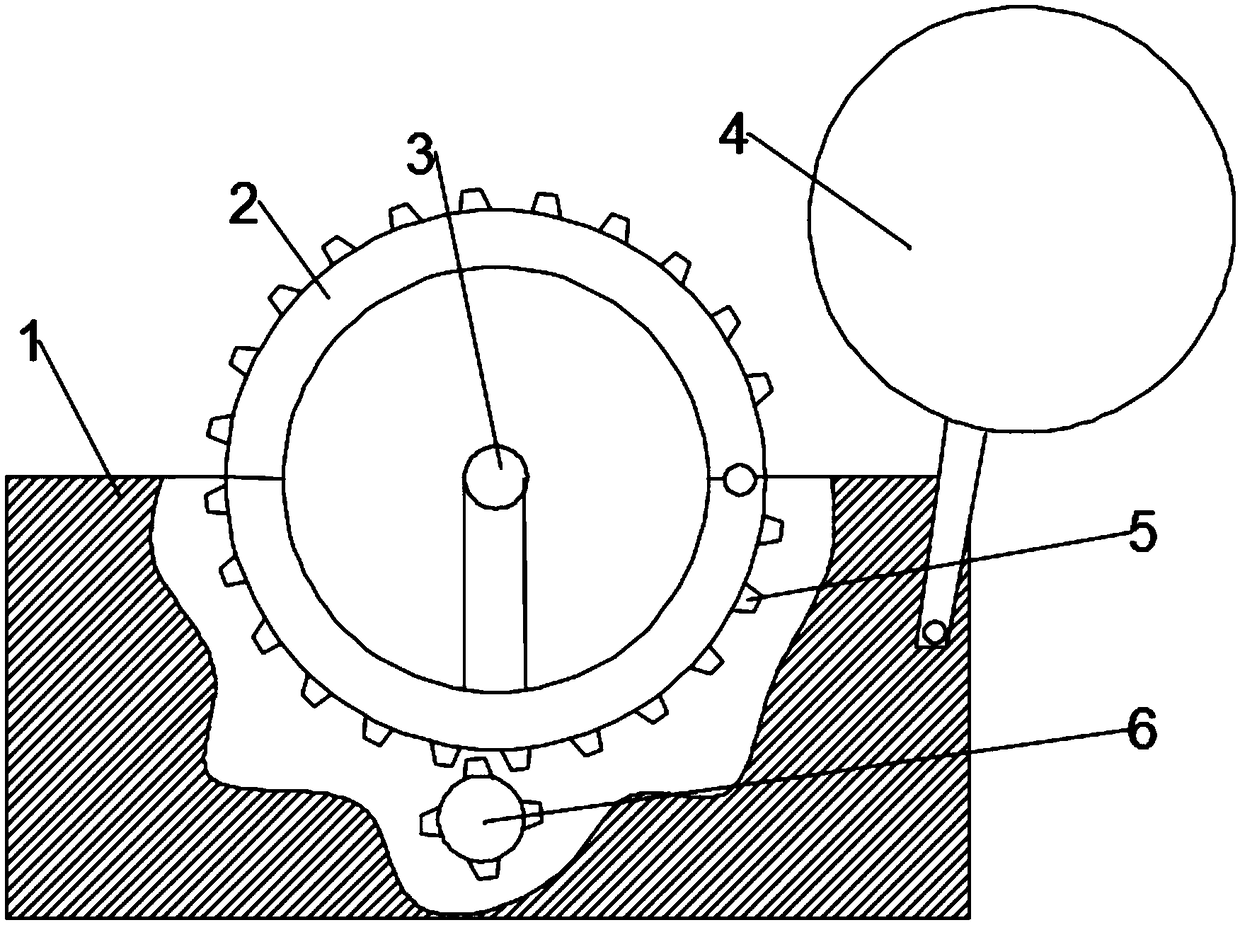

[0014] The reference signs in the drawings of the specification include: installation box 1, upper half cylinder 2, rotating shaft 3, heating plate 4, lower half cylinder 5, and gear 6.

[0015] The embodiment is basically as attached figure 1 Shown: a side sealing packaging device for roll paper, including a mounting box 1, a motor and a connecting rod are fixedly connected in the mounting box 1, a bearing is provided on the top of the connecting rod, a rotating shaft 3 is rotatably connected in the bearing, and the rotating shaft 3 is fixedly connected There is a central placement cylinder, the inner diameter of the placement cylinder is the same as the diameter of the roll paper; the installation box 1 is also connected to the heating plate 4, the outer wall of the heating plate 4 is in contact with the end of the placement cylinder away from the shaft 3, the heating plate The diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com