An entire row reversing conveying device

A conveying device and conveyor belt technology, applied in the field of conveying, can solve problems such as inconvenient operation, low production efficiency, poor continuity, etc., and achieve the effects of improving integrity and reliability, improving conveying efficiency, and shortening conveying cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

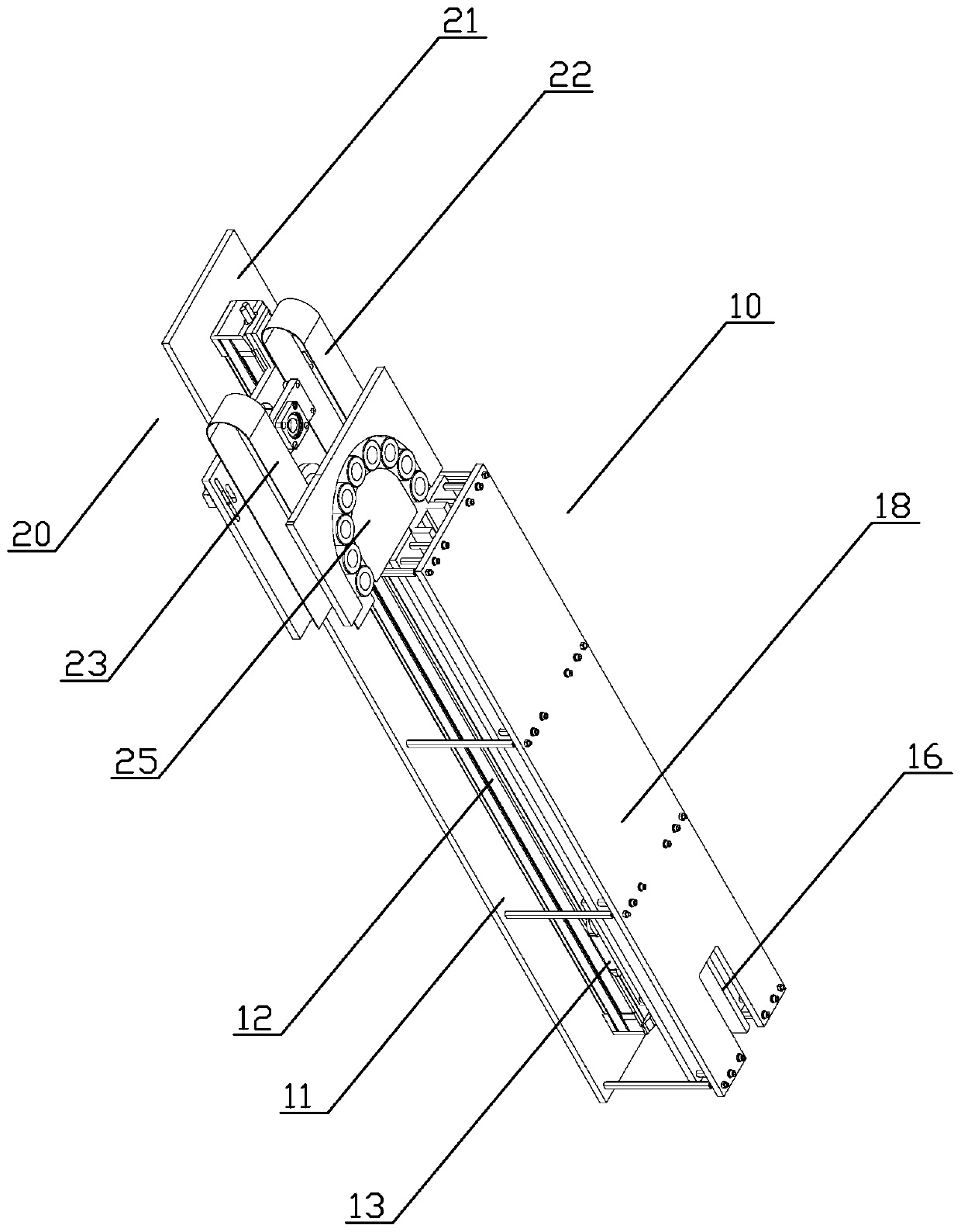

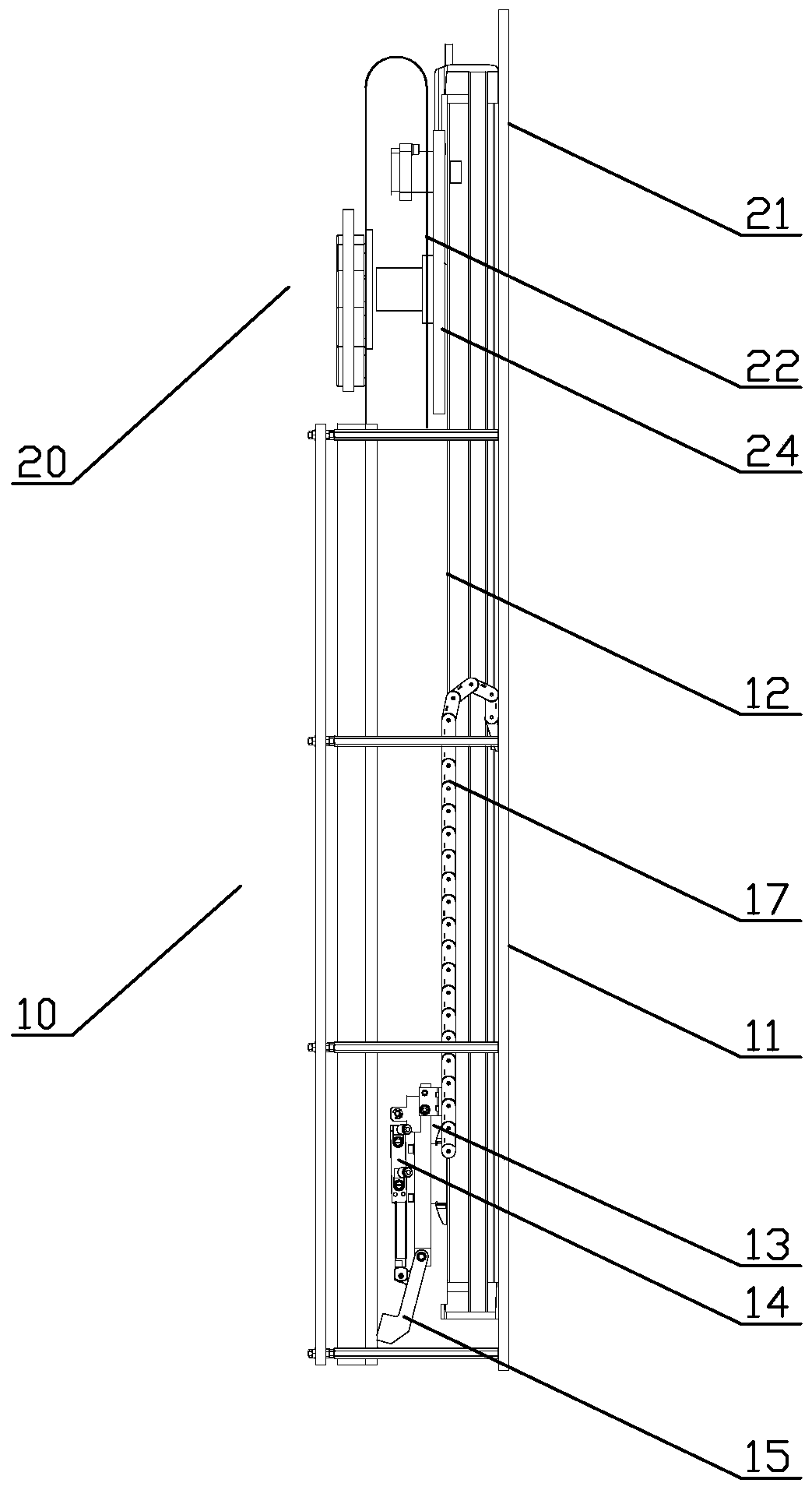

[0024] Such as figure 1 with figure 2 , a full-line reversing conveying device, including a full-line stacking device 10 and a steering conveyor 20, and the full-line stacking device 10 includes a bracket 11, a slide rail 12, a slide table 13, a cylinder 14, a claw hook 15, and a linear limit plate 16 , the slide rail 12 is fixed on the bracket 11, the slide table 13 is movably connected on the slide rail 12, the cylinder 14 is fixed on the slide table 13, and the claw hook 15 is hinged on the On the slide table 13, a limit groove is opened on the linear limit plate 16; the piston rod end of the cylinder 14 is hinged on the claw hook 15, and constitutes a lever mechanism;

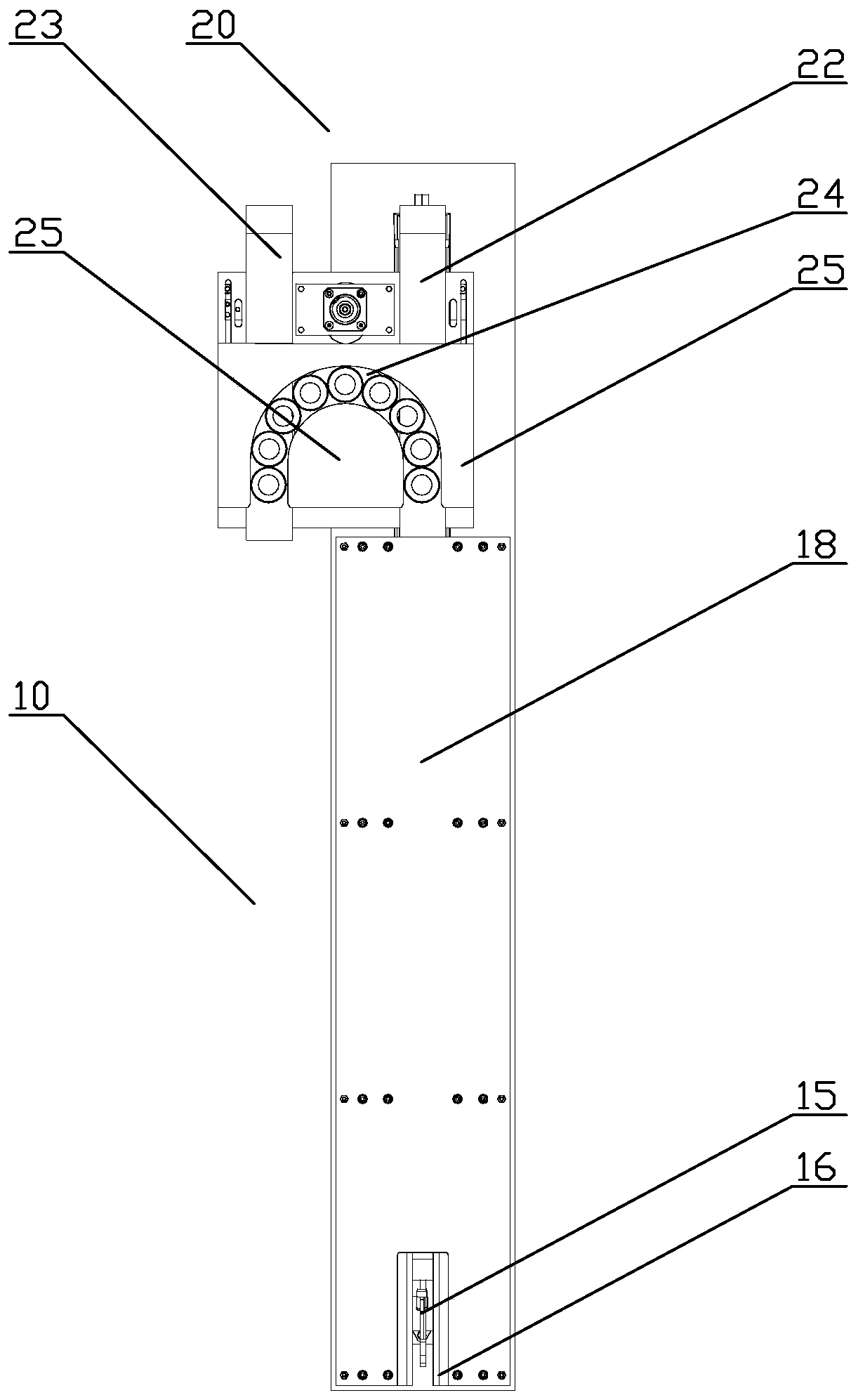

[0025] Such as image 3 , the turning conveying device 20 includes a base 21, a first conveyor belt 22, a second conveyor belt 23, a turntable 24 and an arc-shaped limit plate 25, and the first conveyor belt 22 and the second conveyor belt 23 are parallel Connected to the base 21, the turntable 24 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com