Aluminized paper for aluminum crystal labels and preparation method of aluminized paper

A technology of aluminized paper and labels, which is applied in the direction of chemical instruments and methods, paper/cardboard layered products, adhesive types, etc., which can solve the problems of slow labeling speed, non-universal use, and high price of plastic self-adhesive labels. achieve low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

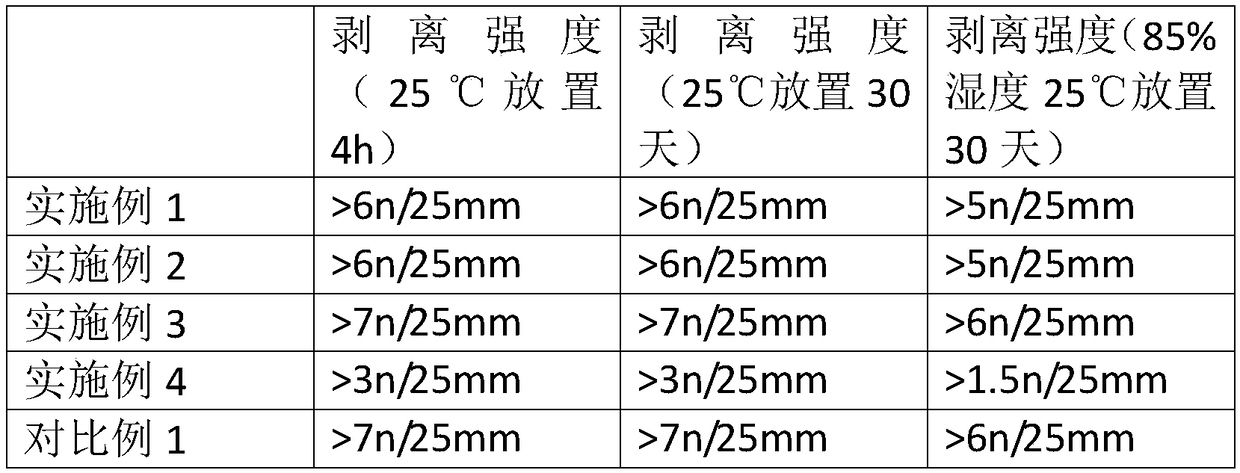

[0016] Embodiment 1-4 prepares the aluminized film paper layer for aluminum crystal label

[0017] The shrinkage rate of the two-way heat-shrinkable PET vacuum aluminized film is 50-70°C, 30%-45% in the longitudinal direction, and 55%-80% in the transverse direction, 32g; the base paper layer material is base paper with a medium wet strength of 32 grams; The wet tensile force of the base paper layer material is ≥8 in the longitudinal direction and ≥4 in the transverse direction; the curing agent is SY-03B.

[0018] The paint of the back coating comprises the following components by weight percentage: 1-8% of carboxymethyl cellulose, 8-15% of glycerol, 0.3-0.8% of lubricating and moisturizing agent (No. 060A01), and 83-90% of water.

Embodiment 1

[0019] The glue layer of the glue layer in Example 1 comprises the following components by weight percentage: 8% curing agent, 1% polyacrylic acid sodium salt, 2% phenolic resin, 40% ethyl acetate, and the balance water.

Embodiment 2

[0020] The glue layer of the glue coating layer in Example 2 comprises the following components by weight percentage: 12% of curing agent, 2% of polyacrylic acid sodium salt, 4% of phenolic resin, 50% of ethyl acetate, and the balance of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com