Aluminum crystal label and preparation method thereof

A label and aluminum crystal technology, applied in the field of aluminum crystal labels and their preparation, can solve the problems of easy bubbling, slow labeling, and easy wrinkling of labels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0020] Embodiment 1-4 prepares the aluminized film paper layer for aluminum crystal label

[0021] The shrinkage rate of the two-way heat-shrinkable PET vacuum aluminized film is 50-70°C, 30%-45% in the longitudinal direction, and 55%-80% in the transverse direction, 32g; the base paper layer material is base paper with a medium wet strength of 32 grams; The wet tensile force of the base paper layer material is ≥8 in the longitudinal direction and ≥4 in the transverse direction; the curing agent is SY-03B.

[0022] The paint of the back coating comprises the following components by weight percentage: 1-8% of carboxymethyl cellulose, 8-15% of glycerol, 0.3-0.8% of lubricating and moisturizing agent (No. 060A01), and 83-90% of water.

[0023] The glue layer of the glue layer in Example 1 comprises the following components by weight percentage: 8% curing agent, 1% polyacrylic acid sodium salt, 2% phenolic resin, 40% ethyl acetate, and the balance water.

[0024] The glue layer ...

Embodiment 5-8 and comparative example 1

[0034] Embodiment 5-8 and comparative example 1 prepare aluminum crystal label

[0035] The paint of the primer layer comprises the following components by weight percentage: 2.1-3.2% of glycol, 1.9-2.8% of ethanol, and the balance of water.

[0036] The aluminized film paper layers prepared in Examples 1-4 and Comparative Example 1 were respectively prepared into the aluminum crystal labels of Examples 5-8, and the preparation method was as follows:

[0037] On the PET layer of the aluminized film paper layer, the concave-convex printing layer and the varnish layer are sequentially coated, and after the primer layer is coated on the back coat layer of the aluminized film paper layer, the printing layer, the varnish layer and the primer layer are dried , that is, the aluminum crystal label is obtained.

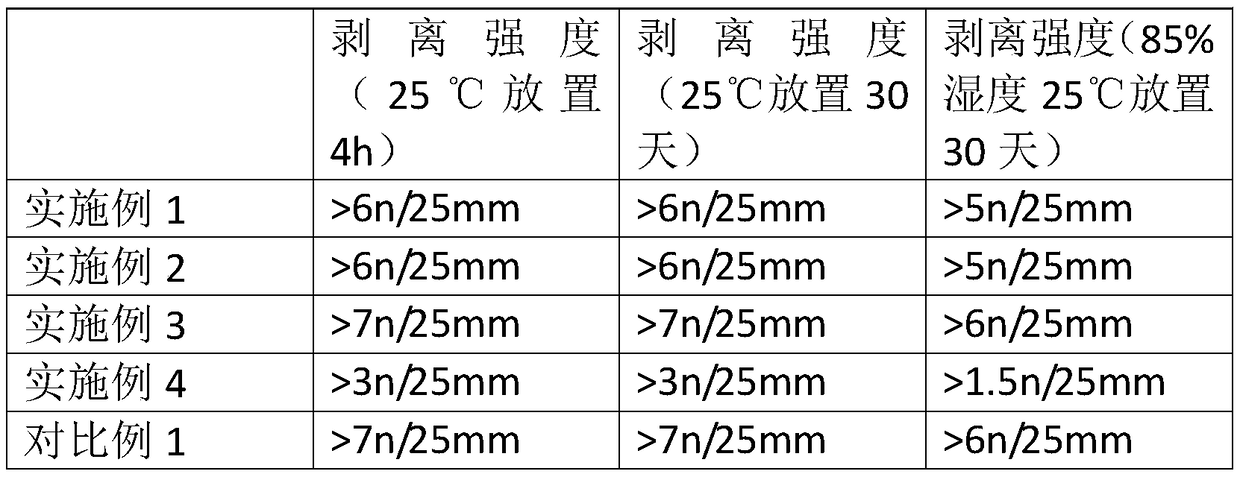

[0038] Test Results:

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com