Material transporting trolley

A material and trolley technology, applied in trolleys, trolley accessories, transportation and packaging, etc., can solve problems such as product quality impact, and achieve the effect of preventing rollover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

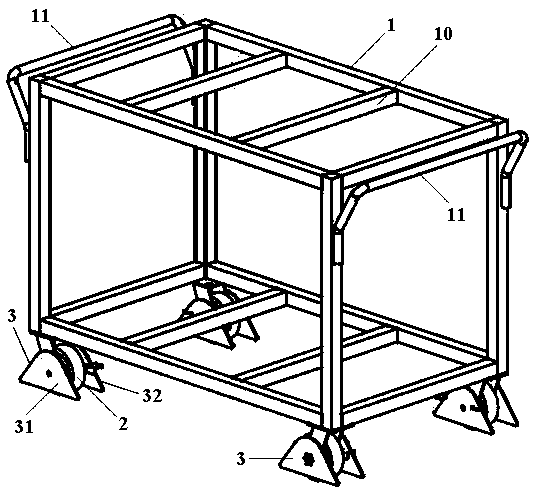

[0024] Please also refer to Figure 1-3 As shown, the embodiment of the present invention provides a material transport trolley, comprising:

[0025] The main frame 1, the top surface of the main frame 1 is used to carry materials;

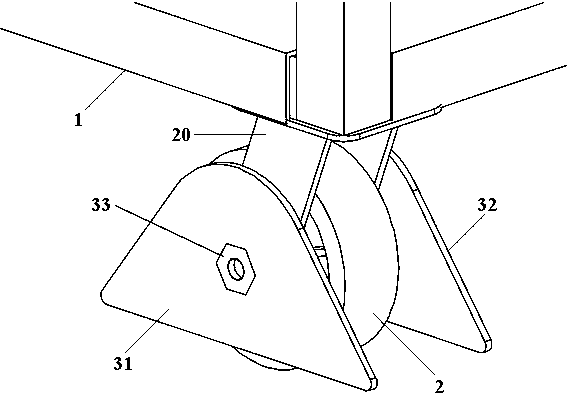

[0026] A plurality of rollers 2 installed on the bottom of the main body frame 1 are used for rolling on the ground;

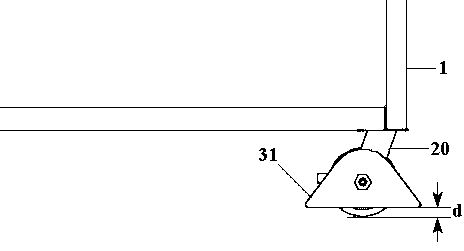

[0027] A support frame 3 installed on each roller 2, the support frame 3 has at least one support piece located outside the roller 2, the bottom surface of the support piece has a predetermined distance from the ground.

[0028] Specifically, the main body frame 1 is a cuboid with a plurality of reinforcing ribs 10 on its top surface for strengthening the support of the loaded materials. As an example, the main frame 1 is 1000 mm long, 600 mm wide, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com