Drainage device for liquid in pulling-out tubular column, tubular column pulling-out structure and tubular column pulling-out method

A technology for pipe strings and cylinders, which is applied in the field of liquid drainage devices in pipe strings, and can solve problems such as operator pollution, equipment pollution, and oil not falling to the ground.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The invention provides a device for draining liquid in a pipe string, such as Figure 4 , Figure 5 and Figure 7 As shown, the liquid drainage device in the lifting pipe string includes: a first fan-shaped cylinder 11, a second fan-shaped cylinder 12, a rubber plate 20 and a locking mechanism 30, and the second fan-shaped cylinder 12 is hinged to the first fan-shaped cylinder 11 Rubber plate 20 is located at the inner wall of the first fan-shaped cylinder 11 and the inner wall of the second fan-shaped cylinder 12, the first fan-shaped cylinder 11 and the second fan-shaped cylinder 12 can be relatively rotated to the closed state, in the closed state, the first The fan-shaped cylinder 11 and the second fan-shaped cylinder 12 drive the rubber plate 20 to surround and form a closed cylinder; the rubber plate 20 is provided with a liquid leakage through hole 201; the locking mechanism 30 can lock the first fan-shaped cylinder 11 and the second fan-shaped column The body ...

Embodiment 2

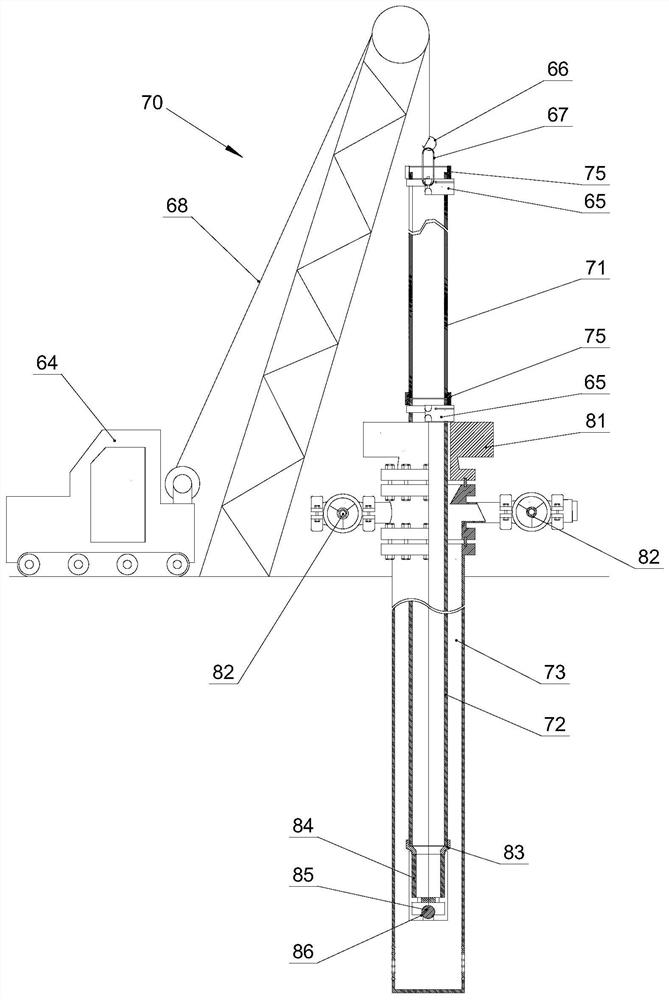

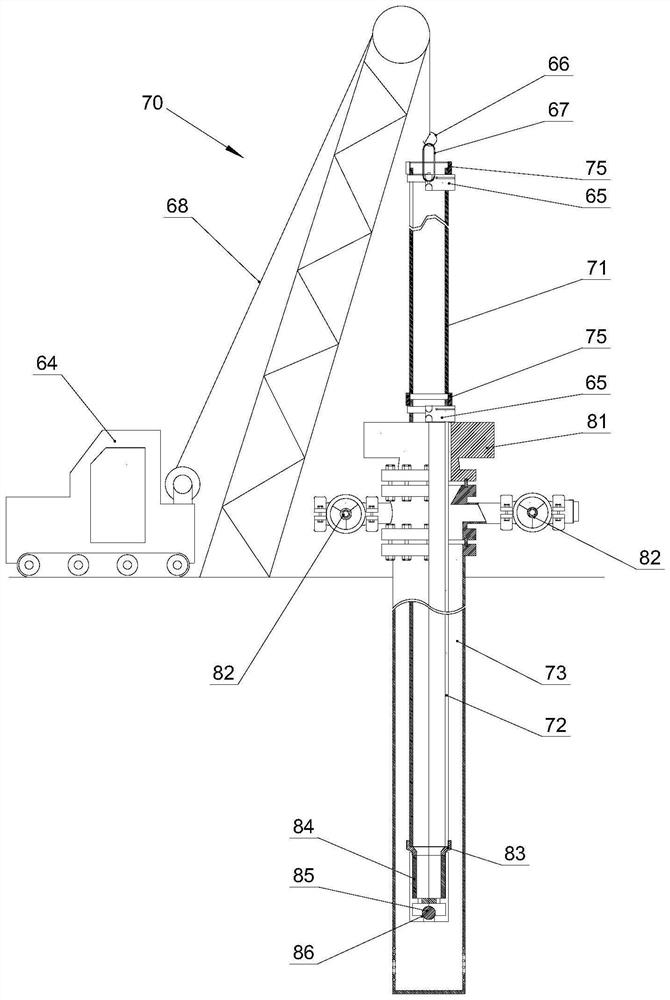

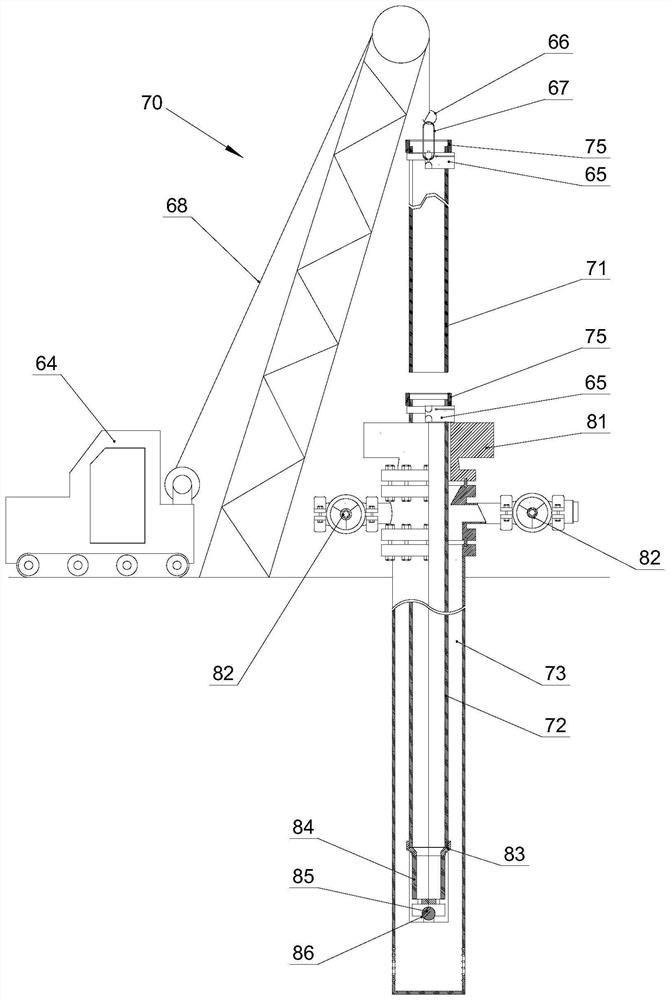

[0078]The present invention provides a pipe string extraction structure, including: an upper oil pipe 71, a lower oil pipe 72, an oil pipe coupling 75, a lifting mechanism 60 and the above-mentioned liquid drainage device in the extraction pipe string, and the upper oil pipe 71 and the lower oil pipe 72 pass through The oil pipe collar 75 is connected; the rubber plate 20 in the liquid drainage device of the lifting string is set outside the upper oil pipe 71 and the oil pipe collar 75; the lifting mechanism 60 is connected with the upper oil pipe 71 for lifting the upper oil pipe 71 upward.

[0079] Using the string lifting structure, the liquid in the string can be sealed and drained to the designated area, which alleviates the technical problem in the prior art that the liquid in the tubing will pour out during the construction of the string of pulling out tubing, and achieve The purpose of the oil well workover operation is to prevent the liquid from falling to the ground w...

Embodiment 3

[0088] The present invention provides a method for pulling out a pipe string, using the above-mentioned pipe string internal liquid drainage device, the pipe string lifting method includes: step S, pulling out 20 sets of rubber sheets in the pipe string internal liquid drainage device Set outside the upper oil pipe 71 and the oil pipe collar 75; step S, lift the upper oil pipe 71 upward, the upper oil pipe 71 moves upward relative to the rubber plate 20, and the liquid in the upper oil pipe 71 flows into the rubber plate 20; step S, the rubber plate 20 The liquid inside is discharged outward through the liquid discharge through hole 201 ; Step S, the upper oil pipe 71 moves upwards and separates from the rubber plate 20 .

[0089] Using the method for pulling out the tubing string, the liquid in the tubing string can be sealed and drained to a designated area, which alleviates the technical problem in the prior art that the liquid in the tubing will pour out when the tubing str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com