Retaining wall reinforcement structure and active repair method for retaining wall inclination

A technology for actively repairing and strengthening structures, applied in the repair of basic structures, basic structure engineering, construction, etc., can solve problems such as the reduction of the internal friction angle of the fill, the occurrence of obvious inclination, and the inclination of the retaining wall, so as to reduce resistance and prevent tilt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

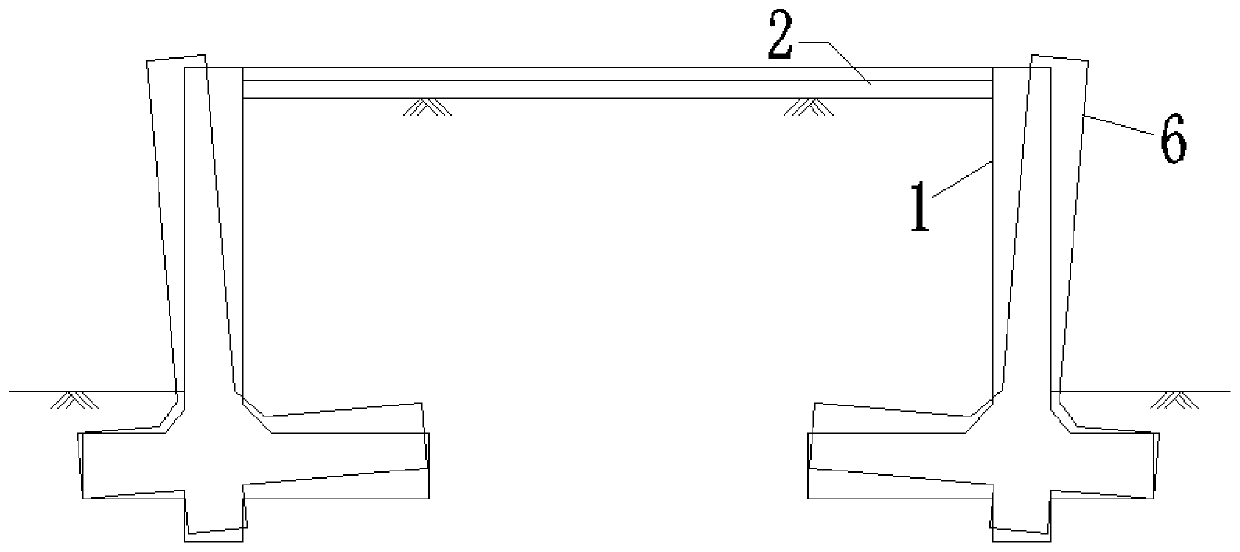

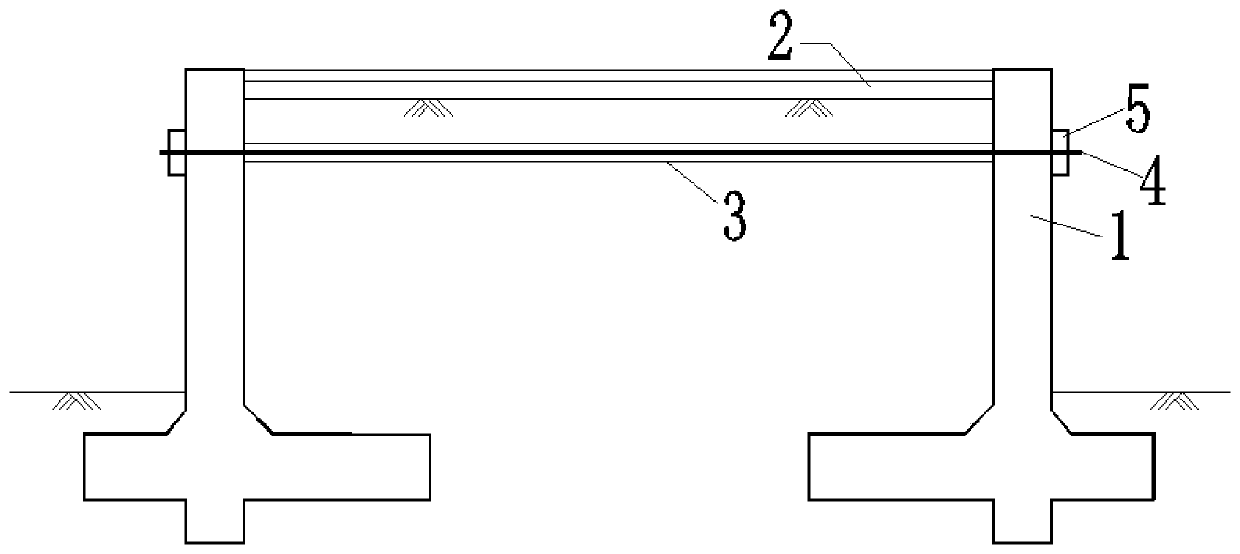

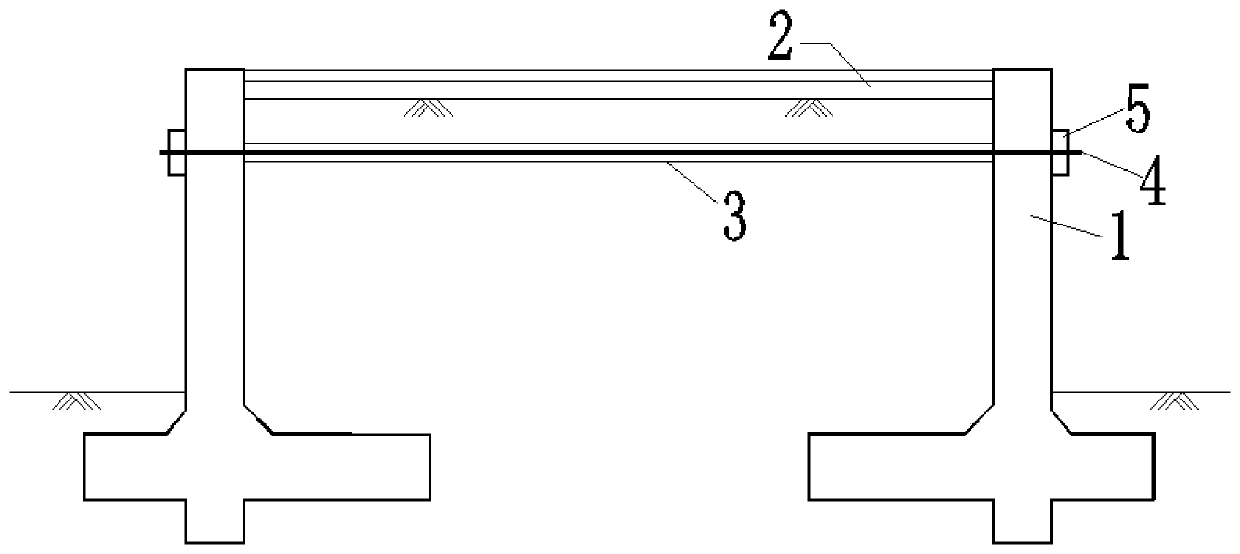

[0033] A retaining wall reinforcement structure of the present invention comprises a retaining wall body 1, a pavement structure and a pavement 2 are arranged between the two retaining wall bodies 1, and the two retaining wall bodies 1 pass through A protective pipe 3 is provided, and a prestressed steel bar 4 is arranged inside the protective pipe 3 , and the prestressed steel bar 4 is fixedly connected to the retaining wall body 1 through an anchor piece 5 .

Embodiment 2

[0035] An active repair method for sloped retaining walls, comprising the following steps:

[0036] S1. Mark the hole position on the main body 1 of the retaining wall on both sides;

[0037] S2, using a drilling rig to perforate according to the route of setting out;

[0038] S3. After the perforation is completed, place the protective pipe 3 in time to prevent the tunnel from collapsing;

[0039] S4, penetrating the prestressed steel bar 4 in the protective pipe 3;

[0040] S5. Tension the prestressed steel bars 4 to the design value, and use anchors for anchoring.

[0041] Specifically, in step S1, the holes on the retaining wall bodies on both sides should be on the same horizontal plane, and should be as close to the upper edge of the retaining wall as possible, and the line connecting the two holes should be perpendicular to the retaining wall.

[0042] Specifically, in step S2, when the distance between the two sides of the retaining wall body is relatively long, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com