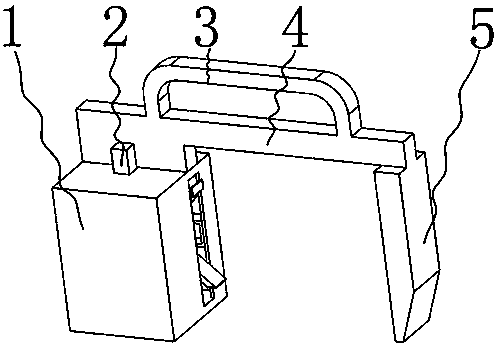

Labor-saving brick clamp device for building engineering

A construction engineering and brick card technology, which is applied in the field of brick cards to improve work efficiency, reduce hand soreness and reduce fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

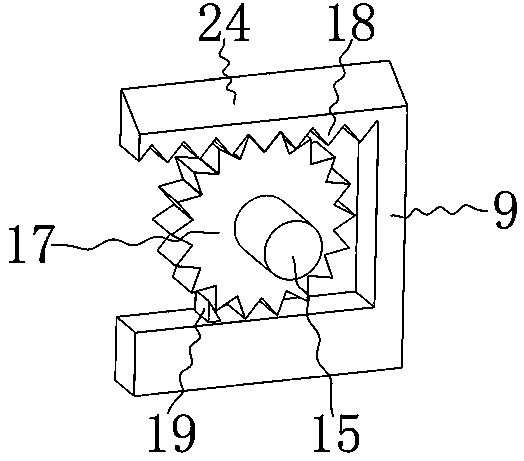

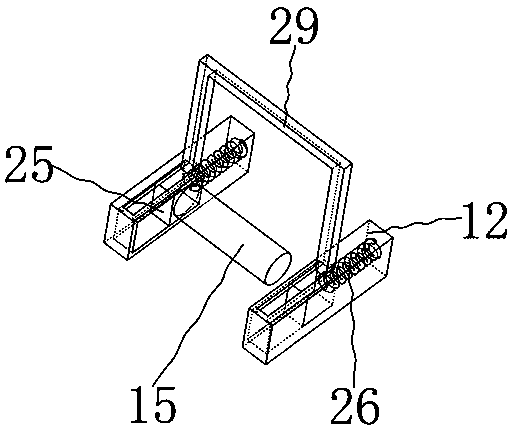

[0060] Specific embodiments: when people use the brick card designed by the present invention, the brick card is pressed down along the brick, and at this time the brick will squeeze the trigger bar 23 located on the upper side of the brick, and the lower side adjacent to the trigger bar The trigger bar is at a position away from the side of the brick; the trigger bar 23 on the upper side of the brick drives the trigger ring 22 to rotate clockwise, and the rotation of the trigger ring 22 will drive the support shaft 15 to rotate through the one-way ring 40; the rotation of the support shaft 15 drives the adjustment The gear 17 rotates; the adjusting gear 17 rotates under the effect of the driving teeth 18 on the U-shaped drive block 9, and the adjusting gear 17 will move along the guide rail block 12 to the side that leans against the brick lug 5; the adjusting gear 17 The movement drives the support shaft 15 to move; the movement of the support shaft 15 drives the trigger stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com