A heat exchange device based on inclined column and heat exchange method thereof

A technology of heat exchange device and inclined column, which is applied in the field of heat exchange device based on inclined column, can solve the problems of slow heating heat exchange speed, slow heating speed, low heating heat exchange efficiency, etc., so as to improve uniformity and improve heat exchange The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

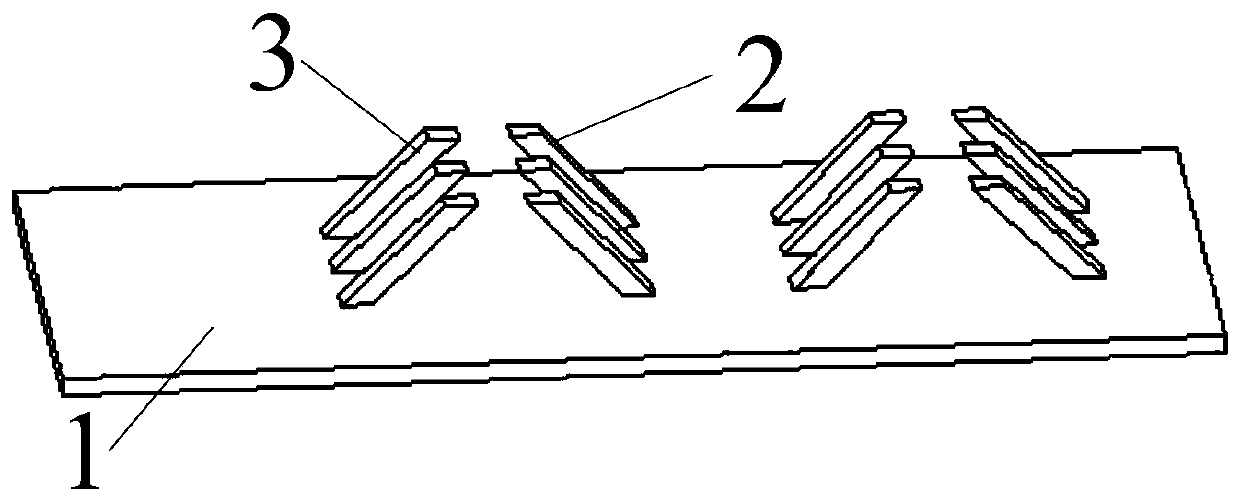

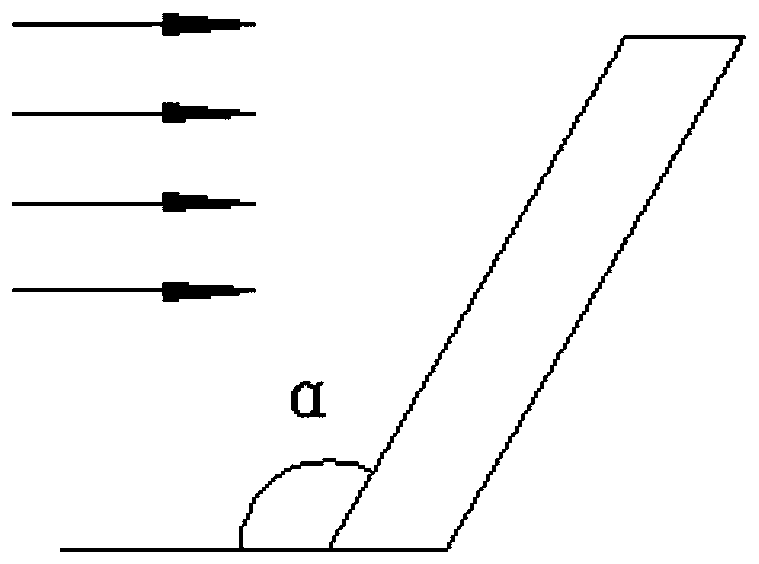

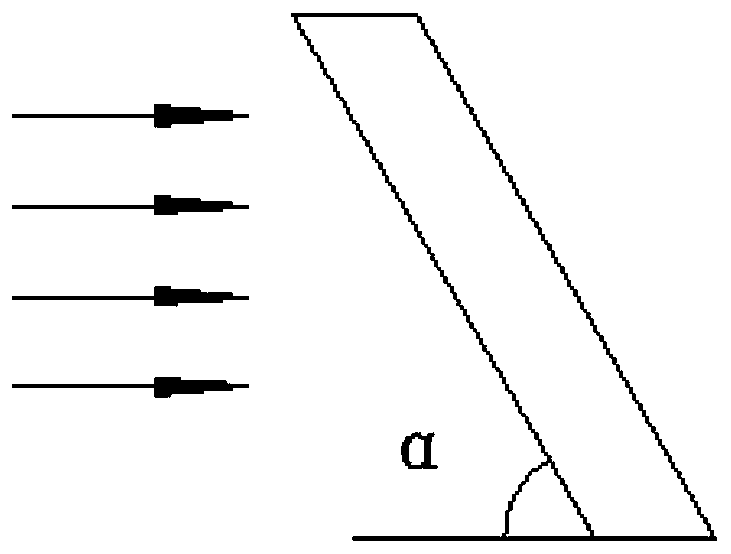

[0044] The front inclined column 3 is shown in Figure 2(a), and the rear inclined column 1 is shown in Figure 2(b). Both the front inclined column 3 and the rear inclined column 2 are oblique quadrangular prisms. The angle between the central axis of the front inclined column and the central axis of the rear inclined column and the installation side of the frame 1 is α, and α is 30°, 40°, 50° or 60°. The cross section of the front inclined column 3 and the rear inclined column 2 is a rectangle whose width is equal to c and length is equal to d, and 5mm≤d≤40mm.

[0045] In this embodiment, α is 50°, c is 25mm, h is 400mm, f is 200mm, s is 900mm, and there is an airflow of 4m / s from the inlet end of the frame to the outlet end, the heat transfer effect simulation diagram is as follows Figure 4(b), the simulated streamline diagram at the front inclined column is shown in Figure 3(b), and the simulated streamline diagram at the rear inclined column is shown in Figure 3(c).

[00...

Embodiment 2

[0049] The front inclined column 3 is shown in Figure 2(c), and the rear inclined column 1 is shown in Figure 2(d). Both the front inclined column 3 and the rear inclined column 2 adopt curved quadrangular prisms. The cross sections of the front inclined column 3 and the rear inclined column 2 are rectangular, and the center line is an arc segment. The concave sides of the front inclined column 3 and the rear inclined column 2 are both facing the air outlet end of the frame 1 . The angle between the line connecting the two ends of the center line of the front inclined column and the line connecting the two ends of the center line of the rear inclined column and the installation side of the frame 1 is α, and α is 50°. The cross section of the front inclined column 3 and the rear inclined column 2 is a rectangle whose width is equal to c and length is equal to d, and 5mm≤d≤40mm.

[0050] In this embodiment, c is 25mm, h is 400mm, f is 200mm, and s is 900mm, and when there is a...

Embodiment 3

[0054] The front inclined column 3 is shown in Figure 2(c), and the rear inclined column 1 is shown in Figure 2(f). Both the front inclined column 3 and the rear inclined column 2 adopt curved quadrangular prisms. The cross sections of the front inclined column 3 and the rear inclined column 2 are rectangular, and the center line is an arc segment. The concave side of the front inclined column 3 faces the air outlet end of the frame 1 . The concave side of the rear inclined column 2 faces the air intake end of the frame 1 . The angle between the line connecting the two ends of the center line of the front inclined column and the line connecting the two ends of the center line of the rear inclined column and the installation side of the frame 1 is α, and α is 50°. The cross section of the front inclined column 3 and the rear inclined column 2 is a rectangle whose width is equal to c and length is equal to d, and 5mm≤d≤40mm.

[0055] In this embodiment, c is 25mm, h is 400mm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com